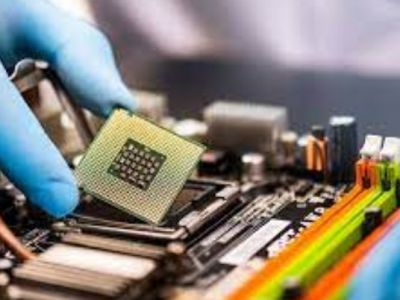

Delving into the complexities of electronic assembly, the exploration sheds light on the unique attributes of Ball Grid Array (BGA) assembly as compared to conventional printed circuit board (PCB) assembly methods. Unveiling its distinctive use of solder balls and high-density connections and examining its impact on electrical performance and thermal characteristics, the narrative navigates through the realm of miniaturization and efficient design facilitated by BGA assembly. The discussion further probes into challenges related to rework, considerations for lead-free applications, and the adherence to industry standards, offering a comprehensive perspective on the pivotal role of BGA assembly in advancing electronic devices.

Ball Grid Array (BGA) assembly differs from other PCB assembly methods in several key aspects:

1. Connection Method:

BGA uses an array of small solder balls for connections between the integrated circuit (IC) and the printed circuit board (PCB). This is in contrast to methods like through-hole assembly or surface-mount technology (SMT), which use different types of leads or pads for connections.

2. Component Packaging:

In BGA assembly, the solder balls are arranged in a grid on the underside of the package, providing a high density of connections in a compact space. Other methods may involve leads or pins extending from the sides or bottom of the component.

3. Density of Connections:

BGA assembly allows for a higher density of connections compared to many other methods. This is particularly advantageous in applications where a large number of connections are required in a limited space.

4. Electrical Performance:

The grid of solder balls in BGA provides better electrical performance, as the shorter path lengths and reduced parasitic inductance contribute to improved signal integrity. This can be a critical factor in high-frequency or high-speed applications.

5. Thermal Characteristics:

BGA assembly typically offers enhanced thermal characteristics due to the even distribution of heat through the solder balls. This is important for applications where efficient heat dissipation is crucial.

6. Rework and Repair Challenges:

BGA assembly can present challenges in terms of rework and repair due to the compact nature of the solder ball grid. Other assembly methods, such as through-hole, may be more accessible for manual rework.

7. Miniaturization:

BGA assembly is often associated with miniaturization efforts in electronic devices. The compact design and high connection density contribute to the development of smaller and more efficient devices.

8. Lead-Free Considerations:

BGA assembly can be adapted for lead-free soldering, aligning with environmental regulations. This may differ from assembly methods that traditionally use lead-based solder.

9. Industry Standards and Guidelines:

BGA assembly may have specific industry standards and guidelines governing its implementation, which can differ from those associated with other assembly methods.

Understanding these differences is crucial for manufacturers and engineers when selecting the most suitable assembly method for a particular application based on factors such as space constraints, performance requirements, and manufacturing capabilities.