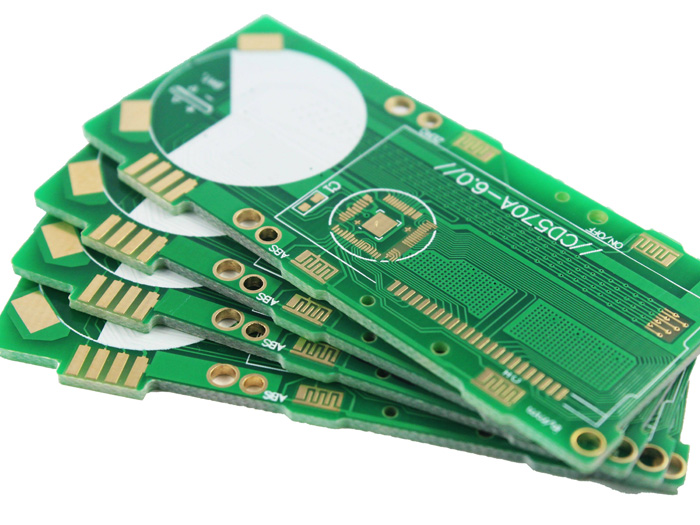

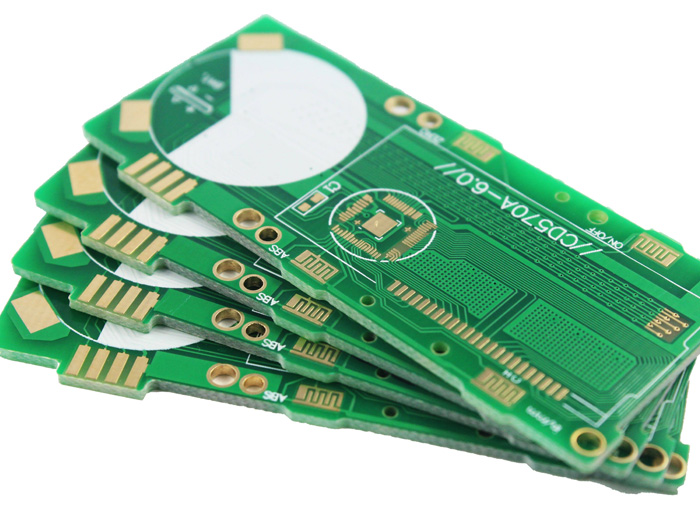

PCBs are essential components of electronic devices. Prototyping helps engineers evaluate the design's functionality before mass production, ensuring the concept's feasibility.

Prototype PCBs have a pivotal role in electronics production. They provide a safety net for catching and correcting potential design errors before full-scale manufacturing begins. The process contributes significantly to the final product's overall efficiency and functionality, often contributing to significant savings in time, costs, and resource allocation.

Creating a prototype PCB generally follows two essential stages:

In this stage, the design concept comes to life in two sub-steps:

The design journey commences with engineers crafting a concept based on the final product's anticipated functionality.

Next, the concept translates into a formal schematic design. This schema depicts the connections between different components on the PCB like resistors, capacitors, and more.

Once the schematic design gains approval, the next stage of creating a physical model commences.

Engineers utilize computer-aided design (CAD) software to develop a tangible model of the printed circuit board (PCB) based on the schematic design. This intricate process requires a meticulous approach to ensure that the physical model accurately represents the intended design while meeting the required specifications.

Lastly, this physical model, or the prototype board, undergoes rigorous testing to identify potential challenges. Any identified issues are debugged, and design revisions ensue until the prototype meets the required standards.

If you are considering using a PCB prototype service, it's important to understand that there are several factors to consider.

Firstly, you should ensure that the service provider you choose has the necessary expertise and experience to produce high-quality PCB prototypes that meet your requirements. This will ensure that you receive a product that is reliable, efficient, and durable.

Secondly, you should consider the cost of the service and whether it fits within your budget. It's important to find a service provider that offers good value for money and is transparent about their pricing structure.

If you have urgent deadlines to meet, you may also want to look for a service provider that offers fast turnaround times. This will ensure that you receive your PCB prototypes in a timely manner and can complete your project on schedule.

Other important factors to consider include the types of PCB materials and designs that are available, as well as the level of customer support that the service provider offers. It's important to choose a service provider that can offer you a range of options and can provide you with the support you need throughout the process.

By taking all of these factors into account, you can choose a PCB prototype service that meets your needs and helps you achieve your goals.

The type of materials used significantly influences the final PCB's performance and cost. Crucially, this depends on the prototype board's intended application and the environment it will operate in.

The complexity of the design can affect the prototyping process and final production. More complex designs require more thorough testing.

The use of high-quality prototype PCBs in electronics manufacturing can offer a wide range of benefits. These PCBs are designed to offer superior performance, durability, and reliability, making them ideal for use in a variety of electronic applications. In addition, they can also help to accelerate the production process, reduce costs, and improve overall efficiency. By using high-quality prototype PCBs, manufacturers can ensure that their products meet the highest standards of quality and performance.Risk Mitigation

Design errors get identified before mass production, substantially reducing the risk of expensive problems further down the line.

Prototype boards contribute to minimizing the time and cost involved in design iterations, reducing the risk of production delays.

Prototype PCBs provide a valuable testing ground for innovative designs. Concepts that appear feasible on paper can be effectively tested and amended as necessary.

Prototype PCBs serve a crucial purpose in electronics manufacturing, offering an invaluable checkpoint before moving to mass production. They allow for design verification, foster cost-effectiveness, and stimulate innovation within the field.

A: A PCB design outlines how the final PCB will look and function. In comparison, a prototype PCB is the physical incarnation of that design, produced for validation and testing purposes.

A: The choice of materials can considerably impact the final PCB’s performance, cost, and its compatibility with the anticipated operating conditions.

Although not strictly obligatory, creating a prototype PCB is a critical step for exhaustive design testing and timely detection of potential issues.

These processes expose any shortcomings or inconsistencies in the prototype, which can be addressed before proceeding to mass production.

Prototype PCBs encourage innovation by offering a safe context to test and refine new designs, thereby fostering the exploration and realization of new ideas.

Using a 24 hours PCB prototype service can significantly expedite the prototyping process, allowing for rapid adjustments and improvements in design, thus ensuring a seamless transition to the final production stage.