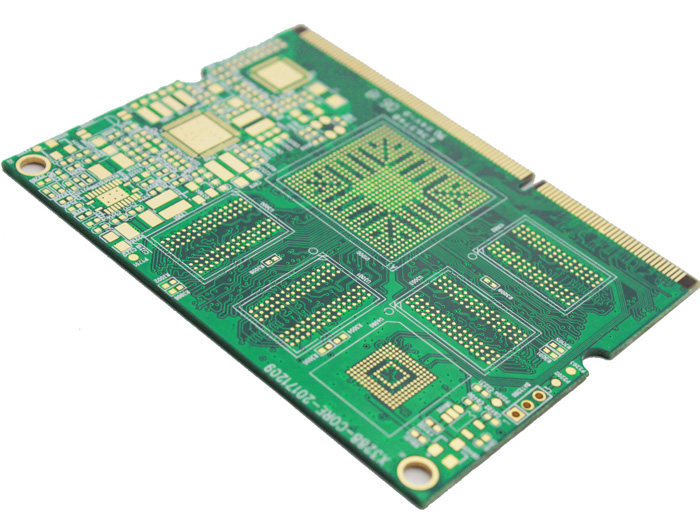

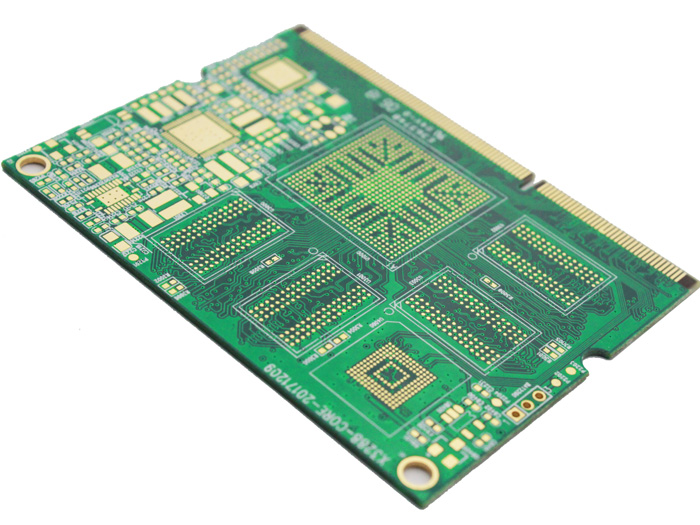

Using a PCB prototype in product development offers advantages such as early error detection through design validation and testing, ensuring the final product's functionality and reliability. Prototyping aids in cost savings by identifying and correcting issues before mass production, accelerating development timelines, and allowing customization of circuit layouts. Improved communication and collaboration among team members and stakeholders, compliance with industry standards, and effective risk management are additional benefits. Prototypes also facilitate user feedback, enhancing the overall usability of the final product, and serve as a blueprint for scalable mass production.

Here are several advantages:

1.Design Verification: PCB prototypes allow designers to validate and verify their circuit designs before mass production. This helps in identifying and rectifying any design flaws or errors early in the development process.

2.Testing and Debugging: Prototypes provide a platform for thorough testing and debugging of the electronic components and their interactions. This helps in ensuring the functionality and reliability of the final product.

3.Cost Savings: Identifying and rectifying issues in the prototype stage is more cost-effective than making changes after mass production has begun. It helps prevent costly mistakes and ensures that the final product meets performance requirements.

4.Time Efficiency: Prototyping accelerates the development process by allowing designers to iterate quickly and make necessary adjustments based on testing results. This helps in meeting tight development timelines.

5.Customization: Prototyping allows for customization and optimization of the PCB layout and component placement. Designers can experiment with different configurations to achieve the best performance and functionality.

6.Risk Mitigation: By building and testing a prototype, developers can identify potential risks and challenges early on. This proactive approach allows for the implementation of risk mitigation strategies before mass production.

7.Collaboration and Communication: Prototypes serve as tangible models that facilitate communication and collaboration among team members, stakeholders, and clients. They provide a clearer understanding of the product's physical form and functionality.

8.Regulatory Compliance: Prototypes help in ensuring that the product complies with industry standards and regulations. This is crucial for products that need to meet specific safety and quality requirements.

User Feedback: Prototypes can be used to gather feedback from end-users, allowing developers to make improvements based on real-world usage scenarios. This user-centric approach enhances the overall usability and satisfaction of the final product, and serve as a blueprint for scalable mass production.