Using a PCB (Printed Circuit Board) prototype board allows you to build and test electronic circuits without the need for soldering or custom manufacturing. Here's a step-by-step guide on how to use a PCB prototype board:

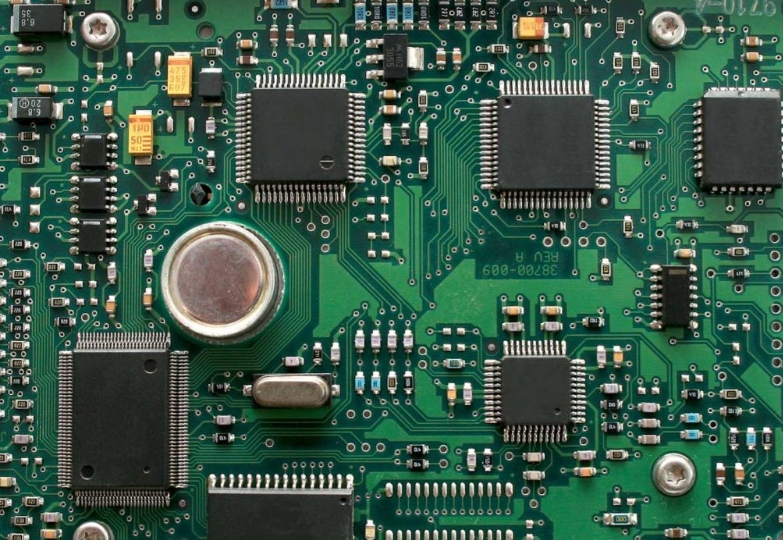

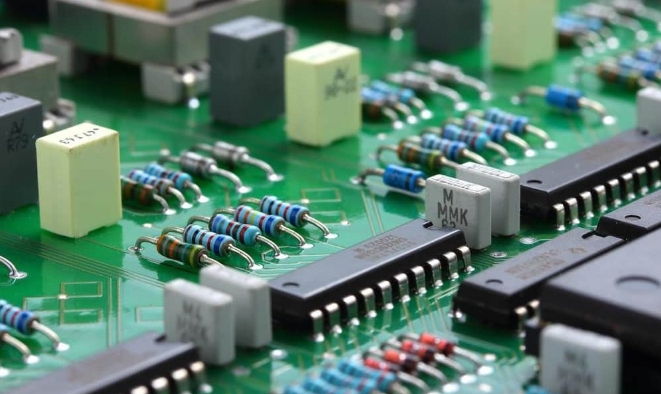

1.Gather the necessary materials: Get a PCB prototype board, electronic components (such as resistors, capacitors, ICs, etc.), a solderless breadboard, and basic tools like wire cutters and strippers.

2.Plan your circuit: Decide on the circuit you want to build and draw a schematic diagram. This will help you understand the connections and component placement on the PCB prototype board.

3.Prepare the PCB: Clean the prototype board using isopropyl alcohol to remove any dirt or residue. This ensures good electrical connections.

4.Component placement: Identify the locations on the PCB where you will place each component. For through-hole components, insert the leads into the appropriate holes on the board. Make sure the component sits flush against the board.

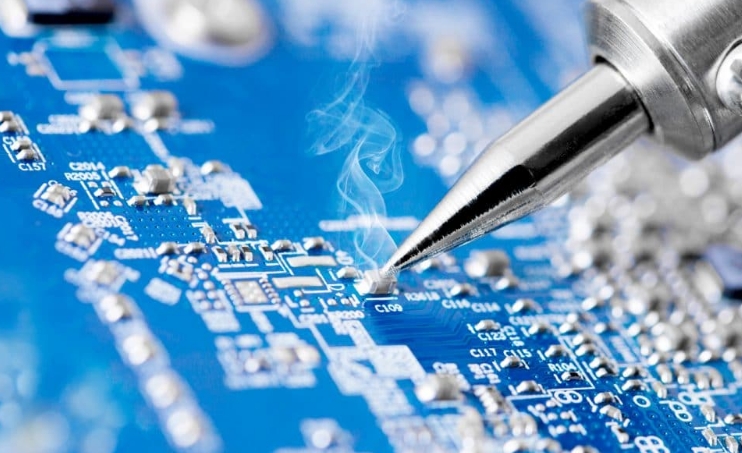

5.Bend and trim leads: On the reverse side of the PCB, bend the leads of the components at right angles to hold them in place. Trim the excess length of the leads using wire cutters, leaving a small length for soldering.

6.Make connections: Use solid-core wire or component leads to connect the different components together. You can bend the wires or leads and insert them into adjacent holes on the board to establish connections.

7.Secure components: To ensure stability, you can add a small drop of hot glue or use adhesive tape to hold the components in place on the PCB.

8.Test the circuit: Once all the connections are made, double-check for any errors or loose connections. Connect the power source and any required input/output devices, and test your circuit to verify its functionality.

9.Troubleshoot and refine: If your circuit doesn't work as expected, carefully inspect the connections, component orientations, and component values. Make any necessary corrections or adjustments to troubleshoot and refine your circuit.

Using a PCB prototype board allows you to iterate on your design and make modifications easily without the need for soldering. It provides a convenient way to build and test circuits before moving to a more permanent soldered PCB.

How to Prepare for PCB Prototyping

Before embarking on the PCB (Printed Circuit Board) prototyping process, it's crucial to assess whether prototyping aligns with your project's needs. While prototyping is invaluable for many projects, it may not be essential for every type. To initiate the prototyping journey, you'll need some fundamental information about your project.

Determining the Need for a Prototype

Prototypes prove exceptionally beneficial when you aim to test your design or conduct a quality assessment of your circuit board. They are particularly useful when implementing a new design for a fresh project. If you have previously achieved success in producing an electronic product using a specific board, you might not necessarily require a prototype. However, if you introduce design modifications or embark on an entirely new PCB design or product, ordering a prototype is advisable.

Through our rapid prototyping service, we can construct test boards with a maximum of eight layers, delivering top-notch standard IPC1 boards utilizing standard RF-4 material. Our prototype services cater to orders ranging from 5 to 100 pieces, with a quick turnaround time of four to five business days. Once you've given your approval for the prototype, you can proceed to order a full-scale production of boards with increased layer counts and diverse materials in larger quantities.

Common Challenges in PCB Manufacturing

The electronics and PCB manufacturing sector currently faces a series of challenges alongside promising opportunities. Amid the imperative to control costs, PCB manufacturing services must explore avenues to capitalize on prevailing trends. This entails considering the integration of technologies beyond their primary domains of expertise while meeting customer demands for highly efficient, eco-friendly manufacturing processes. The prominent trends and challenges in the electronics manufacturing industry are likely to encompass:

Manufacturing vs. Designing:

Your PCB design may appear flawless on paper or a computer screen, but the manufacturing phase can present entirely new hurdles.

For instance, there may be inadequate tolerances between tracks on the board, leading to complications during production.

To address this issue, it's essential to collaborate closely with your PCB manufacturer and take into account their manufacturing capabilities and requirements from the outset of your design process. Ensuring that your design aligns with the manufacturing processes can prevent costly delays and redesigns.

Cost Control: Managing manufacturing costs is a persistent challenge in the PCB industry. With the ever-evolving technology landscape and market demands for cost-effective solutions, manufacturers must constantly seek ways to optimize production processes, reduce material wastage, and improve efficiency.

Technology Integration: Keeping up with technological advancements can be demanding. PCB manufacturers may need to explore incorporating new technologies and processes into their operations to stay competitive. This may involve expanding their expertise into areas like IoT (Internet of Things), flexible electronics, or advanced materials.

Environmental Considerations: As environmental concerns continue to grow, PCB manufacturers must also focus on eco-friendly practices. Customers are increasingly demanding environmentally responsible manufacturing processes and materials. Adhering to sustainability standards and regulations is becoming a critical aspect of the industry.

In summary, before diving into PCB prototyping, evaluate whether it aligns with your project's needs. Prototypes are valuable for testing and ensuring the quality of your design, especially for new projects or significant design changes. Collaborating closely with your PCB manufacturer and staying abreast of industry trends and challenges is essential to navigate the evolving landscape of PCB manufacturing successfully.

Get more knowledge about how to use pcb prototype board please refer Rigaopcb:https://www.rigaopcb.com/