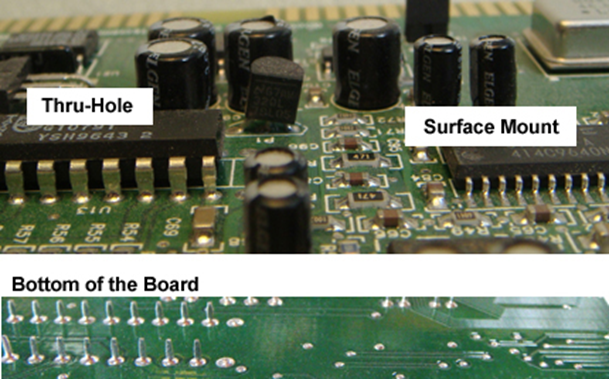

SMT stands for Surface Mount Technology, an innovative process used in the manufacturing of printed circuit boards (PCBs). Unlike traditional through-hole technology (THT), where components are inserted through holes in the PCB and soldered at the base, SMT attaches components directly to the surface of the PCB. This method offers several key advantages, particularly in the areas of production speed, cost, and component miniaturization. In this article, we will explore the meaning of SMT, its process, and its benefits compared to older assembly methods.

Surface Mount Technology (SMT) is a widely used process in electronics assembly, where components are mounted directly on the surface of the PCB rather than through holes. SMT is known for enabling faster and more efficient production of smaller, more compact devices. It is used in virtually every type of electronic product, from consumer electronics to industrial devices, and has revolutionized PCB manufacturing by allowing more components to fit into smaller spaces, thus supporting the trend towards miniaturization in electronics.

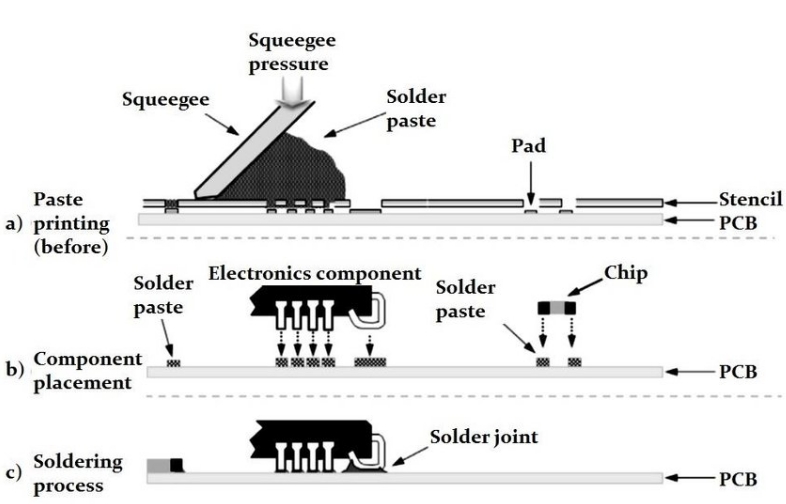

The SMT process involves several stages, each crucial for ensuring the accuracy and functionality of the final product. Here’s a simplified breakdown of how SMT works:

Solder Paste Application: The first step involves applying solder paste onto the PCB’s solder pads using a stencil. The paste is applied in the exact locations where components will be placed.

Placement of Components: Using a pick-and-place machine, surface-mount devices (SMDs) are carefully placed onto the solder-pasted areas of the PCB. This is done with great precision to ensure each component is aligned perfectly.

Reflow Soldering: The PCB with its placed components then moves to a reflow soldering oven. Here, the temperature is gradually increased to melt the solder paste, securely attaching the components to the PCB.

Inspection: Once the soldering process is complete, the PCB is often cleaned to remove any residues and inspected for defects. Automated Optical Inspection (AOI) or manual checks ensure that all components are properly soldered and that no short circuits or other issues exist.

In the context of SMT, SMD refers to Surface Mount Devices—the actual components that are placed on the PCB during the assembly process. These components come in a wide range of types, including resistors, capacitors, diodes, microchips, and connectors, to name a few. SMD components are often smaller and lighter than their through-hole counterparts, which allows them to be used in high-density designs and compact devices.

SMT offers several significant advantages over traditional through-hole technology (THT), including:

Faster Production: The automation involved in SMT allows for quicker manufacturing cycles compared to THT, which requires manual placement of larger components and drilling holes in the PCB.

Cost Efficiency: SMT components are generally smaller and lighter, reducing material costs. Moreover, the automated process minimizes human labor, further driving down production costs.

Higher Component Density: SMT allows for more components to be mounted in a smaller area. This is especially important in today’s space-constrained applications, such as smartphones, wearables, and IoT devices.

Improved Performance: SMT allows for lower inductance and resistance at connection points, which can improve the overall high-frequency performance of the PCB. Additionally, the smaller components reduce electromagnetic interference (EMI) and radiated emissions, making devices more reliable.

| Feature | SMT | THT |

|---|---|---|

| Production Speed | Faster due to automation | Slower, requires manual assembly |

| Component Size | Smaller, more compact components | Larger components with longer leads |

| Cost | More cost-effective in mass production | More expensive due to manual work and material costs |

| Repair | More challenging to repair due to smaller parts | Easier to repair with traditional tools |

| Applications | Ideal for compact, high-density designs | Used for larger components, typically in heavy-duty electronics |

SMT is used extensively across various industries, including:

Consumer Electronics: Smartphones, laptops, and wearable devices all rely on SMT to create smaller, more efficient devices.

Industrial Equipment: SMT is used in the production of programmable logic controllers (PLCs), sensors, and automation systems.

Automotive: Modern vehicles contain a vast array of electronic systems, all of which benefit from SMT, from safety features to entertainment systems.

Medical Devices: Precision medical instruments use SMT to pack more functionality into smaller, reliable devices.

While SMT offers numerous advantages, it is not without challenges:

Repair Difficulty: SMT components are much smaller than through-hole components, making them more difficult to repair, especially when dealing with tiny SMD parts.

Specialized Equipment: The assembly process requires specialized machinery, such as pick-and-place machines and reflow soldering ovens. These can be expensive to maintain, especially for small manufacturers.

Thermal Sensitivity: SMT components are sensitive to temperature, and the solder joints can be affected during temperature changes, potentially leading to failures in some cases.

Surface Mount Technology (SMT) has transformed the electronics manufacturing industry by enabling the production of smaller, more efficient devices. By using Surface Mount Devices (SMDs) and advanced automated processes, SMT allows manufacturers to produce high-density, cost-effective PCBs at faster rates. While it does have its limitations, such as repair difficulty and the need for specialized equipment, the advantages far outweigh the drawbacks in modern electronics production.

As the electronics market continues to evolve, the role of SMT will only grow, especially as miniaturization and high-frequency performance become even more critical in the devices we use every day.