When working on a PCB (Printed Circuit Board) project, whether for prototyping or mass production, understanding the various file types involved is essential. The file types used in PCB design and fabrication not only determine how a circuit board is created but also play a critical role in ensuring the design can be accurately and efficiently produced. Below is an overview of the most commonly used file types in PCB design, schematic drawings, and manufacturing processes.

The most common file type for PCB design is the Gerber file. These files are the industry standard for PCB design data and contain detailed information about each layer of the board, such as copper layers, solder mask layers, and silkscreen layers. Gerber files enable manufacturers to interpret the design and produce the actual board.

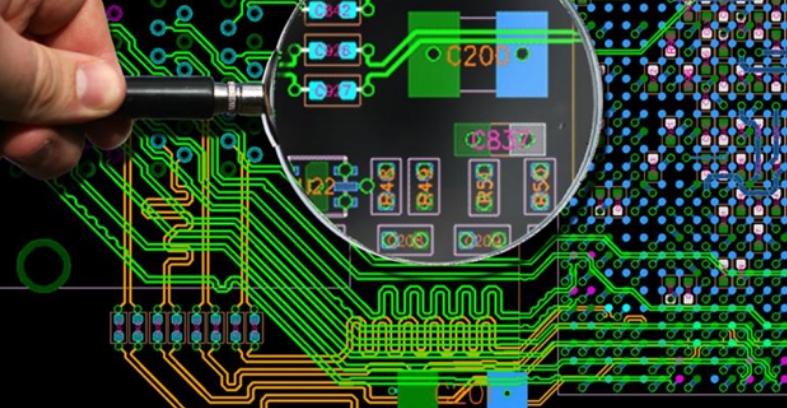

Gerber files are typically generated from PCB design software like Altium Designer, Eagle, or KiCad. These tools provide an intuitive platform for creating complex designs, but once the design is complete, it is exported into a format readable by PCB manufacturers. Common Gerber file extensions include .gbr and .ger.

In addition to Gerber files, PCB schematic drawings are typically represented using formats like .sch or .dsn. Schematic files define the logical connections between components but do not contain physical layout details. These files are crucial during the design phase, allowing engineers to visualize how components are interconnected.

Although schematic files don’t specify physical layout data, they are essential for defining the electrical characteristics of the PCB, which will later be translated into the physical design. Tools like OrCAD or Altium Designer are commonly used to create and modify schematic files.

For PCB fabrication, several critical files are required. These include:

Gerber files: The primary file format used in PCB fabrication, containing information for each layer of the board.

Bill of Materials (BOM): A comprehensive list of all the components needed to build the PCB, including part numbers, descriptions, and quantities. This file helps manufacturers source the required materials.

Pick-and-place files: These files provide the precise location of each component on the PCB, facilitating automated assembly processes.

Drill files: Used to specify the locations and sizes of holes to be drilled in the PCB, crucial for vias and component leads.

ODB++ or IPC-2581 files: These newer formats integrate all the necessary information for PCB manufacturing and assembly into a single file.

Design for manufacturing (DFM) is a process aimed at ensuring a PCB design can be easily and accurately produced. During this phase, the design files are analyzed to identify potential issues that could complicate production, such as component placement conflicts or violations of trace width requirements.

DFM software tools are often used to analyze Gerber files and BOMs to ensure manufacturability before the design is sent to production. This step helps avoid costly rework and delays during the PCB fabrication and assembly stages.

PCB design and assembly involves creating the physical PCB layout and populating it with components. The design phase includes creating the layout, selecting the components, and preparing all the necessary files. Once the design files are complete, the assembly process begins, during which the PCB is populated with components.

This process requires files such as the BOM and pick-and-place files, which guide automated assembly machines. Online tools for circuit board design allow designers to easily create PCB layouts and even order boards directly from the design platform.

The most common file types for PCB designs are Gerber files and schematic files (.sch, .dsn). Gerber files contain detailed layer information, while schematic files define the electrical connections between components.

For PCB fabrication, the essential files include Gerber files, a Bill of Materials (BOM), pick-and-place files, drill files, and optionally ODB++ or IPC-2581 files.

For PCB assembly, the primary files are the Bill of Materials (BOM) and pick-and-place files, which specify the components and their precise locations on the board.

The file types for PCB schematic drawings are typically .sch or .dsn files, which define the electrical connections between components.

Gerber files are crucial for translating the PCB design into a physical board. These files communicate the layer information, such as copper layers and solder masks, to the manufacturer.

Several software tools are available for creating and managing PCB design files. Popular options include:

Altium Designer: Known for its advanced features, Altium supports Gerber, BOM, and pick-and-place files, making it a top choice for professional PCB designers.

KiCad: An open-source tool ideal for hobbyists and smaller projects, KiCad can create Gerber and schematic files.

Eagle: A versatile PCB design tool that can handle both simple and complex designs, integrating well with manufacturing tools.

When selecting a tool, it’s essential to ensure that it can export the necessary files, including Gerber files, schematic drawings, and assembly files, to meet your manufacturing requirements.

Creating a PCB involves several steps, with different file types serving distinct purposes throughout the design and manufacturing process. From Gerber files to schematic drawings and Bill of Materials, each file plays a vital role in ensuring that the final product meets design specifications and can be efficiently fabricated and assembled. Whether designing a PCB for the first time or managing the production process, understanding the file types required at each stage is key to a smooth and successful outcome.