In the electronics manufacturing industry Printed Circuit Assembly (PCA) is a critical process. It involves the assembly of electronic components onto printed circuit boards (PCBs) to create functional electronic devices. As a professional manufacturer, we will delve into what PCA is, how it works, and its significance in the world of electronics.

What is Printed Circuit Assembly (PCA)?

Printed Circuit Assembly, also known as PCB Assembly, is the process of populating a bare PCB with various electronic components like resistors, capacitors, integrated circuits, and connectors to create a functional electronic device. This assembly process is at the heart of all electronic gadgets we use in our daily lives, from smartphones to medical equipment and automotive systems.

How Does Printed Circuit Assembly Work?

Design and Prototyping: The PCA process starts with the design of the PCB. Engineers create a schematic that outlines the placement of components and their interconnections. This design is then converted into a PCB layout. Prototyping is often the next step, where a small batch of PCBs is fabricated to validate the design.

PCB Fabrication: Once the PCB design is finalized, the actual circuit board is manufactured. This involves etching copper traces onto the board and drilling holes for component placement. The PCB's quality and precision are crucial at this stage, as it directly impacts the assembly process.

Component Procurement: The next step is procuring electronic components. These components come in various packages and specifications, and it's essential to select the right ones for the application. Components are sourced from reputable suppliers to ensure quality and consistency.

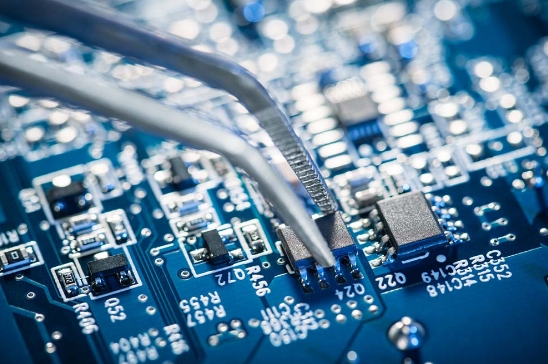

Component Placement: In the assembly process, Surface Mount Technology (SMT) and Through-Hole Technology (THT) are commonly used. SMT involves placing components directly onto the PCB's surface, while THT involves inserting component leads through holes in the PCB. Automated pick-and-place machines are often used for SMT, ensuring high precision and speed.

Soldering: After component placement, soldering is performed to establish electrical connections. Soldering methods can include wave soldering, reflow soldering, or hand soldering for THT components. The solder bonds the component leads to the PCB's copper traces, ensuring electrical conductivity.

Inspection and Testing: Every PCA goes through a rigorous inspection and testing phase to identify defects, such as soldering defects, component misalignment, or open circuits. Automated optical inspection (AOI) and in-circuit testing (ICT) are commonly used methods.

Quality Control: Quality control procedures are in place to ensure the final PCA meets industry standards and customer specifications. This may include compliance with RoHS (Restriction of Hazardous Substances) regulations and other environmental standards.

Packaging and Shipping: Once the PCA passes all quality tests, it is packaged and prepared for shipping to the customer or for integration into larger electronic systems.

Significance of Printed Circuit Assembly

Printed Circuit Assembly is crucial for several reasons:

Efficiency: PCA allows for the mass production of electronic devices, ensuring efficiency and cost-effectiveness.

Precision: Modern assembly techniques provide high precision and accuracy, essential for intricate electronic devices.

Innovation: PCA enables the creation of increasingly complex and advanced electronic systems, driving technological innovation.

Reliability: High-quality assembly processes result in reliable electronic products with fewer defects and longer lifespans.

As a professional manufacturer, we understand the vital role that Printed Circuit Assembly plays in the electronics industry. It is the bridge that transforms electronic designs into functional devices, influencing the performance and reliability of the end product. The continuous advancement of assembly techniques ensures that electronics continue to evolve, meeting the demands of an ever-changing world.

Get more knowledge about guide to Printed Circuit Assembly please refer to Rigaopcb:https://www.rigaopcb.com/