Surface Mount Technology (SMT) is a widely used method in printed circuit assembly (PCA), offering several advantages over traditional through-hole technology (THT). These advantages make SMT the preferred choice for many electronic applications. Here are the key benefits of SMT in PCB assembly:

Miniaturization: SMT components are significantly smaller than their through-hole counterparts. This allows for the creation of smaller and more compact electronic devices, which is especially important in the design of portable gadgets and wearables.

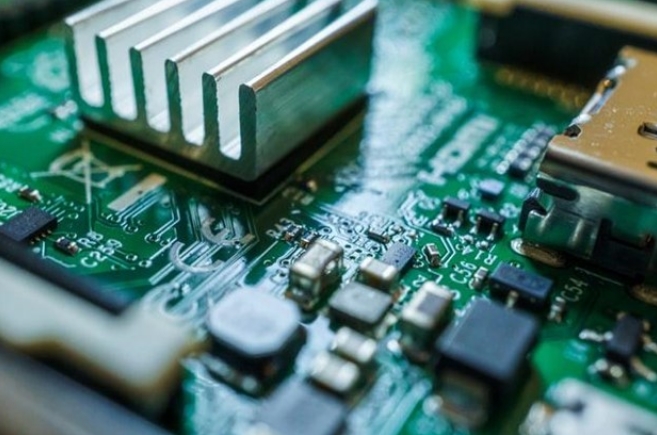

Higher Component Density: SMT enables a higher component density on the PCB. Components are mounted on both sides of the PCB, and their compact size allows for more components to be placed on the same board, increasing functionality.

Improved Performance: With shorter connection lengths and reduced parasitic effects, SMT offers improved electrical performance. It results in reduced signal distortion and better high-frequency characteristics, making SMT suitable for high-speed digital and RF applications.

Cost Efficiency: SMT processes are highly automated, reducing labor costs. Additionally, SMT components are often less expensive than through-hole components. This makes SMT a cost-effective choice, especially for high-volume production.

Enhanced Reliability: SMT reduces the mechanical stress on the PCB since components are attached to the surface rather than passing through holes. This results in a lower likelihood of PCB warping or cracking, improving overall reliability.

Reduced Weight: SMT components are lightweight, contributing to the overall weight reduction of electronic devices. This is critical for applications like aerospace and automotive industries.

Conservation of Space: SMT components do not require holes in the PCB for insertion, which saves valuable real estate on the board. This space can be used for routing additional traces or placing other components.

Improved Heat Dissipation: SMT components are typically closer to the surface of the PCB, allowing for better heat dissipation. Heat can be conducted more efficiently to the PCB, which can then be equipped with heat sinks or other cooling solutions.

Automated Assembly: SMT lends itself well to automated assembly processes, making it faster and more efficient than THT assembly. This results in higher production throughput and reduced assembly time.

High Precision and Accuracy: SMT components are placed with high precision using automated pick-and-place machines. This minimizes errors in component alignment and soldering, leading to improved assembly quality.

Versatility: SMT is compatible with various component packages, including small-outline ICs, resistors, capacitors, and discrete components. This versatility makes it suitable for a wide range of electronic applications.

Better Signal Integrity: With shorter trace lengths and minimal crosstalk, SMT contributes to better signal integrity in high-speed digital and RF circuits.

Environmental Compliance: SMT processes often align with environmental regulations, such as RoHS (Restriction of Hazardous Substances), as they use lead-free solder and have reduced waste.

In summary, Surface Mount Technology (SMT) offers multiple advantages in PCB assembly, including miniaturization, cost-efficiency, improved performance, and enhanced reliability. These benefits make SMT the preferred choice for modern electronic devices, where space, efficiency, and functionality are of paramount importance.

Get more knowledge about advantages of surface mount technology in PCB assembly please refer to Rigaopcb:https://www.rigaopcb.com/