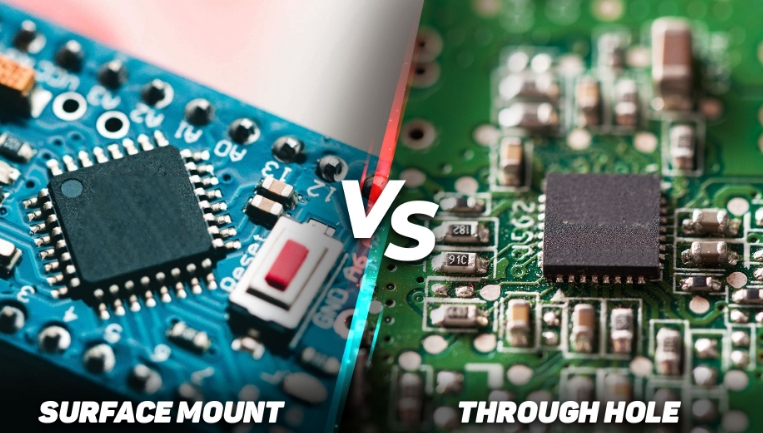

Through-hole assembly and Surface Mount Technology (SMT) assembly are two common methods used in electronic circuit board assembly, and they differ in how electronic components are mounted on the PCB (Printed Circuit Board).

1.Through-Hole Assembly:

Through-hole assembly is an older and more traditional method of mounting components on a PCB. In this process, components have wire leads (or pins) that go through holes in the PCB. These leads are then soldered on the opposite side of the board to establish an electrical connection. Here are some key characteristics of through-hole assembly:

Components with wire leads: Through-hole components typically have wire leads or pins that are inserted through holes in the PCB.

Soldering on the bottom side: The soldering is done on the bottom side of the PCB, and the excess leads are typically trimmed off.

Mechanical stability: Through-hole components are mechanically more robust and are less likely to be dislodged from the PCB due to mechanical stress.

Thicker PCBs: Through-hole components are commonly used in thicker PCBs, which can handle the stress of mounting components with leads.

2.SMT (Surface Mount Technology) Assembly:

Surface Mount Technology (SMT) is a more modern and widely used method for mounting components on PCBs. In SMT assembly, components are mounted directly onto the surface of the PCB. Here are some key characteristics of SMT assembly:

Components without leads: SMT components are typically smaller and do not have wire leads. They have small metal pads on their undersides, which are soldered directly to corresponding pads on the PCB's surface.

Reflow soldering: SMT components are soldered using a reflow soldering process, which involves applying solder paste to the PCB, placing the components, and then heating the entire assembly to melt the solder and create the electrical connections.

Space-saving: SMT components are smaller and allow for denser component placement on the PCB, which is advantageous in compact and miniaturized electronic devices.

Compatibility with automated assembly: SMT assembly is highly compatible with automated assembly processes, making it more efficient and cost-effective for mass production.

In summary, the main difference between through-hole and SMT assembly is the way components are mounted and soldered onto the PCB. Through-hole assembly uses components with wire leads that go through holes in the PCB and are soldered on the other side, while SMT assembly uses components without leads, soldered directly to the PCB's surface. The choice between these assembly methods depends on the specific requirements of the PCB design, manufacturing processes, and the desired characteristics of the final electronic product.

Get more knowledge about the difference between through-hole assembly and SMT assembly please refer to Rigaopcb:https://www.rigaopcb.com/