Optimizing the printed circuit assembly (PCA) process is crucial for improving efficiency, reducing costs, and ensuring the reliability of electronic devices. Here are some steps and strategies to consider when optimizing the PCA process:

1.Design for Manufacturability (DFM):

Begin optimization at the design stage by ensuring that PCB layouts are manufacturable and assembly-friendly. This includes considering component placement, trace routing, and the selection of components to minimize manufacturing challenges.

2.Bill of Materials (BOM) Optimization:

Carefully select components based on cost, availability, and reliability. Consolidate suppliers when possible to reduce lead times and costs.

Consider alternative components with shorter lead times or better pricing without compromising performance.

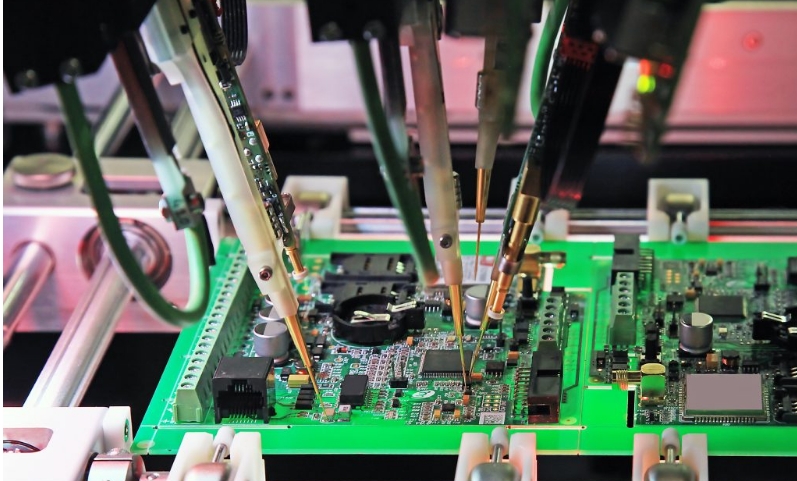

3.Automated Assembly:

Invest in automated assembly equipment and technology, such as pick-and-place machines, soldering robots, and automated inspection systems. This reduces manual labor, improves accuracy, and increases throughput.

4.Surface Mount Technology (SMT):

Utilize SMT components and assembly techniques for higher-density PCBs. SMT components are smaller, lighter, and faster to assemble compared to through-hole components.

5.Quality Control:

Implement rigorous quality control measures at various stages of assembly, including visual inspection, automated testing, and functional testing. This helps detect defects early and reduces rework.

6.Lean Manufacturing:

Adopt lean manufacturing principles to eliminate waste, reduce cycle times, and optimize the flow of materials and information throughout the PCA process.

7.Component Inventory Management:

Maintain an efficient component inventory management system to avoid stockouts and excess inventory. Just-in-time (JIT) inventory practices can help reduce carrying costs.

8.Process Documentation:

Develop comprehensive assembly process documentation, including assembly instructions, work instructions, and quality control procedures. Standardizing processes ensures consistency and reduces errors.

9.Employee Training:

Provide training and certification programs for assembly personnel to enhance their skills and knowledge. A well-trained workforce is essential for efficient assembly and quality control.

10.Supply Chain Optimization:

Work closely with suppliers to establish reliable supply chains. Develop contingency plans for critical components to mitigate risks of disruptions.

11.Continuous Improvement:

Implement a culture of continuous improvement (Kaizen) to regularly review and optimize the PCA process. Encourage employees to suggest and implement improvements.

12.Design for Test (DFT):

Design PCBs with testability in mind. Incorporate test points, built-in self-test (BIST) features, and boundary scan testing to simplify the testing and debugging process.

13.Environmental Considerations:

Consider environmentally friendly assembly processes and materials, such as lead-free solder, to comply with environmental regulations.

14.Reliability Testing:

Perform reliability testing on assembled PCBs to ensure they meet performance and durability requirements under various operating conditions.

15.Cost Analysis:

Continuously monitor and analyze the cost of the PCA process to identify areas for cost reduction without compromising quality.

By implementing these strategies and continuously monitoring and refining the PCA process, you can achieve improved efficiency, reduced costs, and higher-quality electronic products.

Get more knowledge about Printed circuit assembly process optimization please refer to Rigaopcb:https://www.rigaopcb.com/