In the fast-paced world of electronics, time is of the essence. Whether you're a startup racing to launch a new product or an established company looking to stay ahead of the competition, quick turn printed circuit board (PCB) assembly is crucial. This article delves into the benefits of fast turn PCB assembly, the importance of quick turnaround times, and how to choose the right service provider to meet your needs.

Quick turn PCB assembly services are designed to reduce the time it takes to get your printed circuit board assemblies from concept to production. In an industry where technology evolves rapidly, being able to produce quick turn PCBs can be the difference between success and failure. Shorter lead times mean faster prototyping, quicker iterations, and ultimately, a faster time to market.

Time to market is a critical factor for any product development cycle. Delays in PCB manufacturing can lead to missed opportunities and lost revenue. By opting for quick turn PCB prototypes, you can significantly shorten your development cycle, allowing you to bring your products to market faster and stay ahead of the competition.

One of the most significant advantages of quick turn PCB assembly is the reduced turnaround times. Some service providers can deliver prototype PCBs in as little as 24 hours, enabling rapid testing and iteration. This quick turnaround is essential for projects with tight deadlines or those that require multiple design revisions.

Exceptional customer service is a hallmark of reputable quick turn PCB assembly providers. From the initial consultation to final delivery, these providers prioritize clear communication and responsive support. This ensures that any issues are promptly addressed, saving you time and reducing stress.

Despite the emphasis on speed, quality should never be compromised. Reliable quick turn PCB assembly services adhere to stringent quality standards, employing state-of-the-art equipment and rigorous testing procedures. This ensures that your quick turn circuits are not only delivered quickly but also meet the highest quality standards.

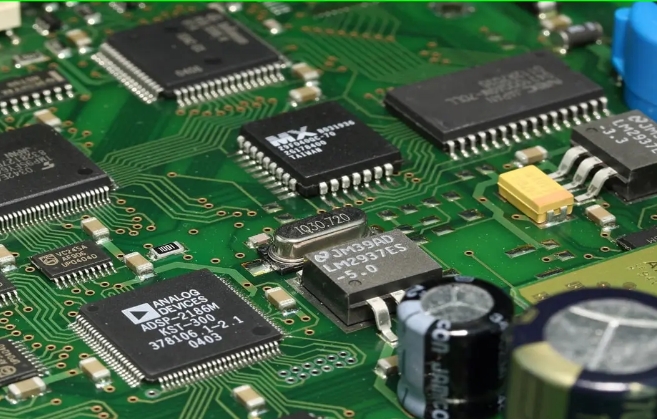

The first step in the process is PCB fabrication, where the physical board is created based on your design specifications. Advanced manufacturing techniques and state-of-the-art machinery are used to produce high-quality boards with precision and accuracy. This stage is crucial for ensuring the reliability and performance of your printed circuit board assemblies.

Once the boards are fabricated, the next step is sourcing the components. Reliable quick turn PCB assembly providers have established relationships with component suppliers, allowing them to quickly procure the necessary parts. This efficient sourcing process helps to further reduce lead times and ensures that your project stays on schedule.

The final stage is the assembly process, where the components are placed and soldered onto the boards. Automated assembly lines and skilled technicians work together to ensure that each board meets the specified requirements. Advanced inspection and testing procedures are employed to verify the quality and functionality of the assembled boards.

When selecting a quick turn PCB assembly service, it's essential to evaluate their turnaround times. Look for providers that offer flexible options, such as 24-hour or 48-hour turnaround for prototype PCBs. This flexibility allows you to choose the service that best fits your project's timeline and requirements.

Quality should never be sacrificed for speed. Ensure that the service provider adheres to industry standards and employs rigorous quality control measures. This includes using state-of-the-art equipment, conducting thorough inspections, and performing functional testing on all assembled boards.

Exceptional customer service is vital for a smooth and successful project. Choose a provider that offers clear communication, responsive support, and a collaborative approach. This ensures that any issues are promptly addressed and that you have a positive experience throughout the project.

One of the best ways to assess a service provider's capabilities is by reviewing case studies and customer testimonials. Look for examples of similar projects and read about the experiences of other clients. This can provide valuable insights into the provider's reliability, quality, and customer service.

Quick turn PCB assembly is a service that focuses on reducing the time it takes to produce and assemble printed circuit boards. This allows for faster prototyping, testing, and product development.

Some quick turn PCB assembly providers offer turnaround times as short as 24 hours for prototype PCBs. The exact time can vary based on the complexity of the design and the provider's capabilities.

Choose a reputable service provider that adheres to industry standards and employs rigorous quality control measures. Look for providers with positive reviews, case studies, and testimonials that highlight their commitment to quality.

Key factors to consider include turnaround times, quality standards, customer service, and the provider's track record. Evaluate their capabilities, review case studies, and ensure they offer clear communication and responsive support.

Quick turn PCB assembly reduces lead times, allowing for faster prototyping and product development. This can help you bring your product to market sooner, reducing development costs and increasing potential revenue.

Exceptional customer service ensures a smooth and successful project. Clear communication, responsive support, and a collaborative approach help address any issues promptly, saving you time and reducing stress.

Quickly assembling printed circuit boards is a big improvement in the electronics field. It helps with faster production, better customer service, and top-notch quality.

Choosing the right quick turn PCB assembly service can help you launch products faster. This will keep you competitive. It will also help you reach your project goals with confidence. Whether you're developing quick turn PCB prototypes or scaling up to full production, understanding the nuances of quick turn PCB assembly will help you make informed decisions and achieve optimal results.