In the realm of electronics manufacturing, the intricate dance of components and circuits comes together within the domain of PCB assembly, a cornerstone of modern technology. The amalgamation of circuit card assembly, PCB fabrication, and a medley of soldering techniques orchestrates the symphony that powers our gadgets, devices, and machinery.

At its core, circuit board fabrication encompasses an intricate process, intertwining various methodologies to create the backbone of electronic systems. PCB design and assembly serve as the initial steps, laying the groundwork for the subsequent stages. Here, the integration of electronic components begins, utilizing both surface mount technology (SMT) and through-hole assembly.

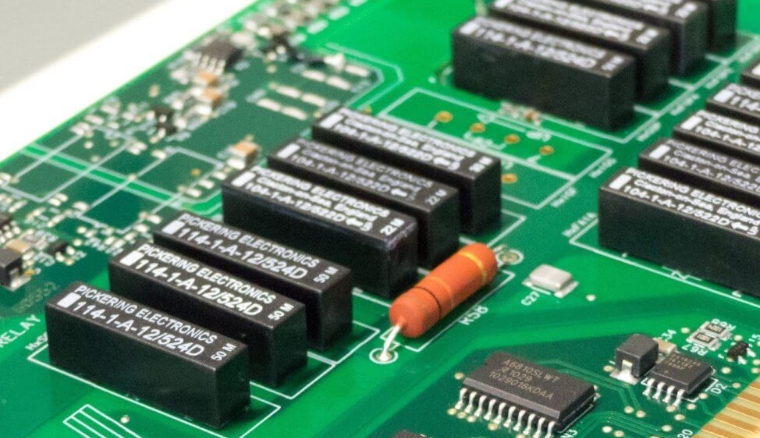

Surface mount technology stands as a hallmark in electronics manufacturing, enabling the mounting of components directly onto the surface of the PCB. Its finesse lies in the meticulous placement of tiny electronic parts, enhancing efficiency and allowing for compact designs. Conversely, through-hole assembly, a more traditional technique, involves components inserted into pre-drilled holes on the PCB, fostering robust connections and durability.

The heart of PCB manufacturing lies in its intricate soldering techniques. Soldering, an art unto itself, solidifies the union between components and the circuit board. Whether through reflow soldering, wave soldering, or hand soldering, the precision and skill employed determine the integrity and functionality of the final product.

The PCB manufacturing process unfolds in a sequence of meticulous steps. It commences with the design phase, where engineers conceptualize the layout and connections of the circuit board. This blueprint undergoes meticulous scrutiny before transitioning to the fabrication stage, where the physical PCB is produced through a series of etching, layering, and printing processes.

Once the board is fabricated, the electronic component integration stage begins. This phase demands adeptness and precision, ensuring components are placed accurately and securely. This leads to the crucial phase of soldering, where the connections between the board and components are meticulously forged. The soldering process, when executed flawlessly, results in durable, reliable connections crucial for the functionality of the final product.

Circuit board production encapsulates an intricate ballet of technologies, each step crucial in shaping the efficiency and reliability of the end product. From PCB design to component integration, from surface mount technology to soldering techniques, each facet plays a pivotal role in the evolution of electronic systems.

In conclusion, the mastery of circuit card assembly encompasses an array of disciplines and techniques. Electronics manufacturing thrives on the harmonious interplay of PCB design, fabrication, and assembly techniques. As technology advances, the art of soldering and PCB assembly continues to evolve, ushering in a new era of innovation and efficiency in the realm of electronic devices.