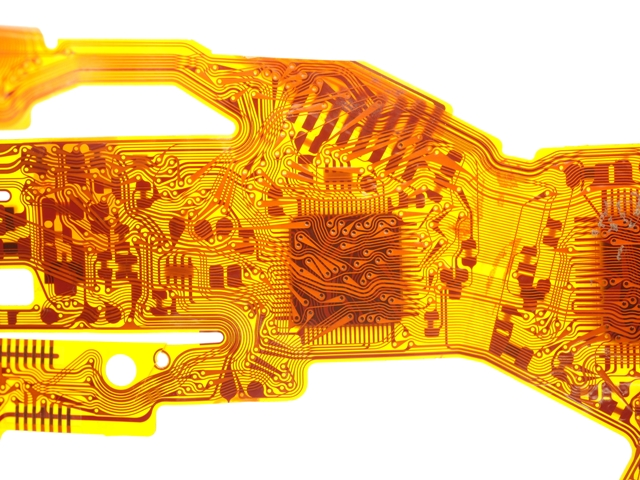

Flexible printed circuit assemblies utilize various components, often chosen for their compatibility with the flexible nature of the circuit. Commonly used components include:

1.Surface Mount Devices (SMDs): These components are directly mounted onto the surface of the flexible circuit. Examples include resistors, capacitors, diodes, and integrated circuits.

2.Flexible Integrated Circuits (Flex ICs): Custom-designed integrated circuits that can bend and flex with the flexible PCB, often used in applications where space and weight are critical.

3.Connector Systems: Flexible circuits frequently incorporate connectors for interfacing with other electronic devices. These connectors allow for reliable electrical connections while accommodating the bending and flexing of the circuit.

4.Flexible Displays: In applications such as flexible displays, organic light-emitting diodes (OLEDs) or other flexible display technologies may be integrated into the flexible circuit assembly.

5.Flexible Sensors: Components like sensors, such as strain gauges or temperature sensors, can be integrated into flexible circuits for applications in wearables, medical devices, or other sensor-based systems.

6.Microcontrollers and Microprocessors: These components provide the processing power for the electronic device and can be mounted on flexible circuits to enable computing functionalities.

7.Flexible Batteries: In some applications, flexible printed circuit assemblies may include thin and flexible batteries, especially in devices with curved or irregular shapes.

8.Flexible Printed Antennas: Antennas designed to be flexible can be integrated into flexible circuits, particularly in wireless communication devices.

9.Light Emitting Diodes (LEDs): Flexible circuits may incorporate LEDs for indicators or lighting purposes, especially in applications where a flexible form factor is essential.

10.Conductive Inks and Adhesives: In addition to traditional solder, conductive inks and adhesives are used in flexible circuit assemblies to provide electrical connections while maintaining flexibility.

The selection of components depends on the specific requirements of the application and the intended use of the flexible printed circuit assembly. The goal is to ensure that all components can withstand the bending and flexing of the circuit while maintaining reliable electrical connections and overall functionality.