In the realm of electronics enthusiasts, DIY PCB board fabrication has become an increasingly popular endeavor. Understanding the PCB board fabrication process is essential for those looking to create their circuits affordably and efficiently. This guide will walk you through the steps of DIY PCB board fabrication, providing insights into cost-effective methods to achieve cheap PCB board fabrication.

DIY PCB Board Fabrication: Unveiling the Process

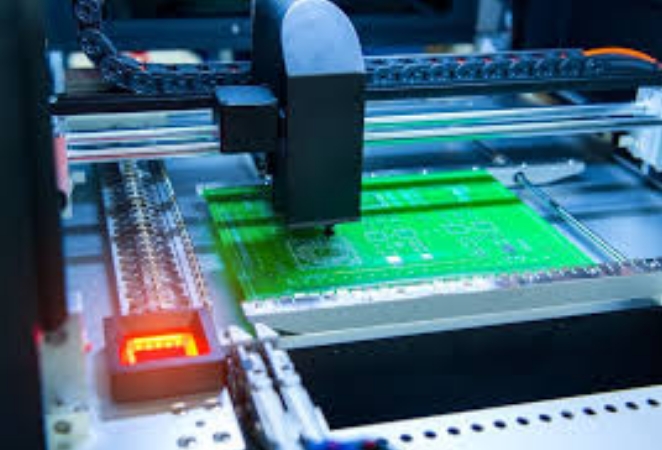

DIY PCB board fabrication involves a series of steps that transform a raw substrate into a functional printed circuit board. The process typically begins with designing the circuit layout using software tools. Once the design is finalized, it's time to move on to the actual fabrication.

The Steps of DIY PCB Board Fabrication: From Concept to Reality

Design Phase: Utilize PCB design software to create a layout that matches your circuit requirements. Ensure proper placement of components and traces for optimal functionality.

Material Selection: Opt for cost-effective yet reliable materials. Many DIY enthusiasts choose materials like copper-clad boards for their balance of performance and affordability.

Transfer the Design: Print the circuit design onto a transparency or special PCB transfer paper. This serves as a guide for transferring the design onto the raw PCB material.

Etching Process: Use an etchant solution to remove excess copper from the board, leaving behind the circuit traces. This step demands careful attention to detail to avoid over-etching.

Drilling Holes: Employ a drill to create holes for component placement. Ensure precision to avoid damaging the circuit traces.

Component Placement: Affix the electronic components onto the board following the design. Soldering is a crucial skill here, and DIYers often prefer affordable soldering kits for this purpose.

Quality Check: Thoroughly inspect the board for any defects or errors. Conduct continuity tests to ensure proper connections.

Affordable Innovations: Cheap PCB Board Fabrication Techniques

For those on a budget, several strategies can help achieve cheap PCB board fabrication without compromising quality:

Optimize Design: Minimize the complexity of your design to reduce the amount of material and production time.

Bulk Material Purchases: Buy materials in bulk to take advantage of discounts and reduce per-unit costs.

DIY Etchant Solutions: Create your etchant solution at home using common household items to cut down on chemical costs.

Reuse and Recycle: Salvage components from old electronics to reduce expenses on new components.

Conclusion: Empowering DIY Enthusiasts

In conclusion, DIY PCB board fabrication is an empowering journey for electronics enthusiasts. Understanding the PCB board fabrication process and implementing cost-effective strategies can make this endeavor not only educational but also budget-friendly. By embracing innovation and frugality, anyone can embark on the exciting path of crafting their circuits through DIY PCB board fabrication.