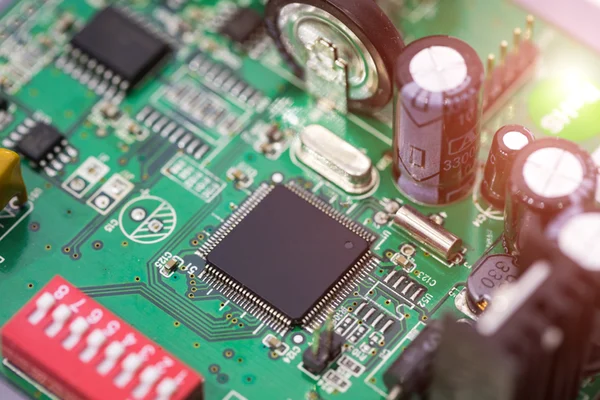

As professionals in the field of electronic manufacturing, understanding the intricacies of circuit card assembly pricing is pivotal. This article aims to shed light on the multifaceted factors that influence the cost of circuit card assembly, providing insights into the considerations that shape pricing strategies in the industry.

1. Complexity and Design intricacy: Unraveling the Puzzle

One of the primary determinants of circuit card assembly pricing lies in the complexity and design intricacy of the circuitry. Elaborate designs with intricate components or advanced technologies often translate to higher manufacturing costs.

2. Quantity Matters: Navigating Economies of Scale

The volume of circuit card assemblies being produced significantly impacts the pricing dynamics. Economies of scale come into play, with larger production volumes generally leading to reduced per-unit costs.

3. Material Choices: The Building Blocks of Cost

The selection of materials used in circuit card assembly plays a crucial role in determining its price. High-quality, specialized materials may increase costs, while cost-effective alternatives could lead to more budget-friendly solutions.

4. Technological Advancements: Innovate or Expire

The incorporation of cutting-edge technologies and features in circuit card assembly can elevate its price. As technology evolves, staying at the forefront of innovation may contribute to a higher manufacturing cost.

5. Manufacturing Processes: From Blueprint to Reality

The chosen manufacturing processes influence pricing. Whether utilizing traditional methods or advanced techniques like surface-mount technology (SMT), each approach carries its own set of cost considerations.

6. Customization and Specialization: Tailoring for Uniqueness

The level of customization or specialization required in circuit card assembly can impact pricing. Tailoring solutions to meet specific needs often involves additional costs but can be essential for certain applications.

7. Quality Assurance and Testing: Ensuring Reliability

Rigorous quality assurance measures and testing procedures contribute to the overall cost. Ensuring the reliability and functionality of each circuit card assembly adds value but also incurs additional expenses.

8. Labor Costs: Skilled Hands, Worth the Investment

The expertise and labor required for circuit card assembly play a crucial role in pricing. Skilled professionals contribute to the precision and quality of the assembly, justifying their impact on the overall cost.

9. Market Dynamics: Navigating Supply and Demand

The ever-changing landscape of market trends and demand for electronic components influences pricing. Understanding market dynamics is crucial for manufacturers to adapt their pricing strategies accordingly.

10. Geographic and Regional Influences: Navigating the Global Landscape

Geographic location and regional factors can introduce variations in circuit card assembly prices. Understanding the global context helps manufacturers adjust their pricing strategies to remain competitive.

In essence, the pricing of circuit card assembly is a tapestry woven from various threads, each representing a different consideration in the manufacturing process. As professionals, navigating this intricate landscape requires a holistic understanding of these factors to provide clients with cost-effective and high-quality solutions.