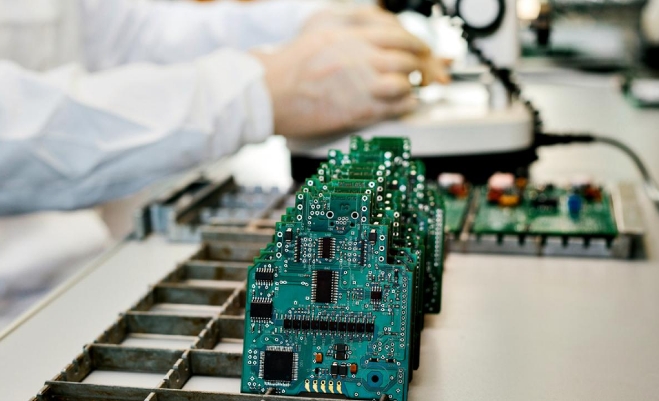

The complexity of a Circuit Card Assembly (CCA) significantly influences its price, a relationship shaped by various factors. Firstly, complex CCAs often necessitate the use of highly specialized and high-quality materials, such as high-density interconnect technologies, leading to elevated material costs. Secondly, the manufacturing processes become more intricate, involving precision assembly, advanced soldering techniques, and specialized testing procedures, which require additional labor, equipment, and time, contributing to increased manufacturing costs. Additionally, the higher component count and diversity amplify costs, and the overall complexity of the design, coupled 69with the adoption of advanced technologies, raises development costs. In summary, the complexity of a CCA impacts its price through heightened material, manufacturing, testing, and design costs.

Let’s take a closer look at these influencing factors:

1. Material Costs: As the complexity of a CCA increases, the need for specialized and high-quality materials often grows. Advanced technologies, such as high-density interconnects, may be required, leading to higher material costs.

2. Manufacturing Processes: More complex CCAs often require more intricate manufacturing processes, including precision assembly, advanced soldering techniques, and specialized testing procedures. These processes may involve more labor, equipment, and time, contributing to higher manufacturing costs.

3. Component Count and Diversity: A complex CCA typically includes a higher number of components and may involve a greater diversity of electronic elements. Each additional component and the complexity of integrating them into the assembly can add to the overall cost.

4. Testing and Quality Assurance: Complex CCAs may require more extensive testing and quality assurance procedures to ensure that all components function correctly and the assembly meets performance specifications. This can involve additional testing equipment, time, and skilled personnel.

5. Design Complexity: The complexity of the circuit design itself can impact the price. Highly intricate and advanced designs may require more sophisticated engineering expertise, simulation tools, and validation processes, contributing to increased development costs.

6. Technology and Innovation: Cutting-edge technologies and innovations often come with higher costs, especially if they are relatively new or require specialized manufacturing processes. The adoption of advanced technologies can contribute to the complexity and cost of a CCA.

7. Volume of Production: The volume of CCAs being produced also influences the cost. In some cases, the economies of scale may apply, reducing the cost per unit for larger production runs. However, for low-volume or custom designs, the fixed costs of development and tooling may be spread over fewer units, resulting in a higher cost per unit.

8. Compliance and Certification: Certain applications, especially in industries like aerospace, medical devices, or automotive, may require adherence to strict regulatory standards and certifications. Meeting these standards can increase the complexity and cost of the CCA.

In summary, the complexity of a circuit card assembly affects its price due to increased material costs, more intricate manufacturing processes, a higher component count, additional testing and quality assurance requirements, the complexity of the design, the use of advanced technologies, and considerations related to production volume and compliance.