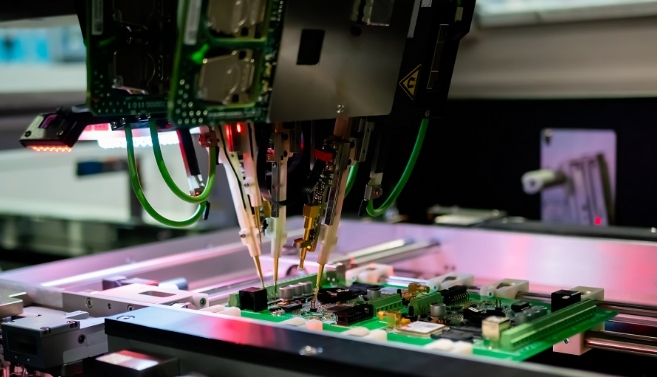

Circuit card assembly testing, often referred to as PCB (Printed Circuit Board) testing, is a crucial step in the electronics manufacturing process. It involves evaluating the functionality, reliability, and quality of assembled circuit boards before they are integrated into electronic devices. The primary goals of circuit card assembly testing are to identify and rectify any defects, errors, or malfunctions in the circuitry to ensure that the final product meets the specified requirements and standards.

Importance of Circuit Card Assembly Testing in Electronics Manufacturing:

Quality Assurance: Circuit card assembly testing is essential for maintaining high-quality standards in electronics manufacturing. It helps identify and rectify defects early in the production process, reducing the likelihood of faulty products reaching the market.

Reliability: Testing ensures that the assembled circuit boards function reliably under normal operating conditions. This is crucial for the overall reliability of electronic devices, especially those used in critical applications such as medical equipment, aerospace, and automotive systems.

Compliance with Specifications: Manufacturers need to adhere to specific design specifications, industry standards, and regulatory requirements. Circuit card assembly testing verifies whether the assembled boards meet these specifications, ensuring compliance with safety and performance standards.

Cost Reduction: Identifying and fixing defects early in the manufacturing process is more cost-effective than dealing with issues after the product has been fully assembled. Circuit card assembly testing helps prevent costly recalls and rework.

Fault Detection: Testing helps detect and isolate faults or defects in individual components, solder joints, traces, and other elements of the circuit board. This allows for targeted troubleshooting and correction.

Process Optimization: Continuous monitoring and analysis of testing results contribute to the optimization of the manufacturing process. Manufacturers can identify areas for improvement, refine production processes, and enhance overall efficiency.

Customer Satisfaction: Ensuring that electronic devices are free from defects enhances customer satisfaction. Reliable and high-quality products contribute to positive user experiences and help build a reputable brand image.

Prevention of Field Failures: Comprehensive testing reduces the risk of field failures, which can be costly and damaging to a company's reputation. Early defect detection minimizes the chances of products failing in real-world applications.

Risk Mitigation: Circuit card assembly testing helps mitigate the risks associated with manufacturing variations, component tolerances, and other uncertainties. It provides a level of assurance regarding the performance and functionality of the final product.

In summary, circuit card assembly testing is a critical step in the electronics manufacturing process, playing a pivotal role in ensuring the production of high-quality, reliable, and compliant electronic devices.