Circuit card assembly involves the use of various soldering techniques to join electronic components to printed circuit boards (PCBs). The choice of soldering technique depends on factors such as the type of components, the PCB design, and the manufacturing requirements. Here are some common soldering techniques used in circuit card assembly:

1. Surface Mount Technology (SMT): This is the most widely used soldering technique for modern PCB assembly. Surface mount components have small, flat leads or no leads at all, and they are mounted directly onto the surface of the PCB. SMT involves using solder paste, which is applied to the PCB using a stencil, and then components are placed on top of the paste. The assembly is then heated in a reflow oven, causing the solder to melt and create a strong electrical connection.

2. Through-Hole Technology (THT): In this technique, components with wire leads are inserted into holes drilled in the PCB. The leads protrude through the other side of the board, and they are soldered to create a connection. THT is commonly used for components that require a strong mechanical connection or for components that generate a lot of heat.

3. Wave Soldering: This technique is primarily used for through-hole components. The PCB is passed over a wave of molten solder, which creates solder joints on the exposed leads of the through-hole components. Before wave soldering, components are often temporarily held in place using adhesive or mechanical fixtures.

4. Hand Soldering/Iron Soldering: Skilled technicians can use soldering irons to solder components manually. This technique is often used for rework or repair tasks, as well as for small-scale production. It allows for precision control over the soldering process, especially in situations where automated methods might not be practical.

5. Reflow Soldering: This technique is part of the SMT process and involves heating the entire assembly in a reflow oven. The solder paste reflows, creating solder joints between the components and the PCB. Reflow soldering is suitable for mass production and ensures consistent and reliable solder joints.

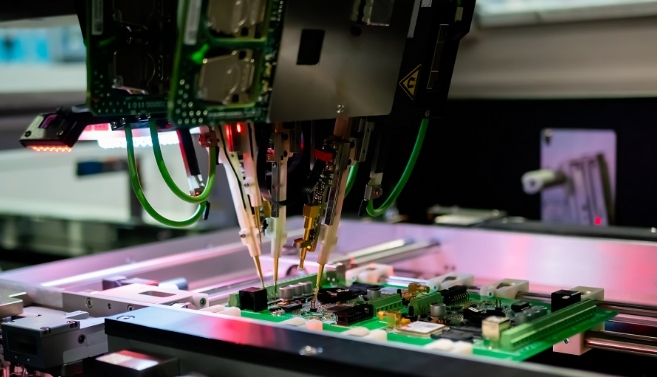

6. Selective Soldering: This technique is often used when a combination of through-hole and surface mount components is present on the same PCB. Selective soldering machines target specific areas for soldering, allowing for precise application of solder to particular components.

These soldering techniques are chosen based on the specific requirements of the PCB design and the components being used in the circuit card assembly process.