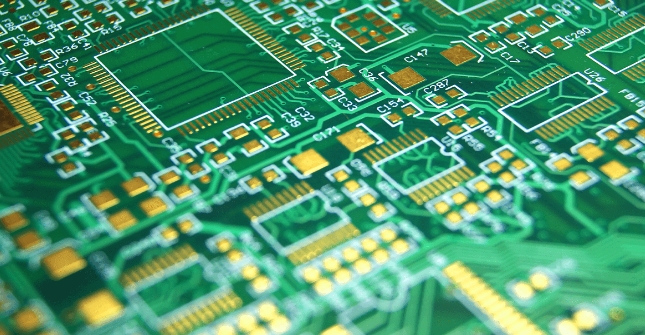

The design phase of printed circuit assembly(PCA) is a critical stage that can significantly impact the performance, reliability, and manufacturability of electronic devices. Here are key factors to consider during the design phase of a printed circuit assembly:

1. Circuit Layout and Schematic Design:

Clearly define the circuit requirements and specifications.

Ensure proper signal integrity, minimizing noise, crosstalk, and impedance mismatches.

Optimize the circuit layout to minimize signal path lengths and reduce electromagnetic interference (EMI).

Use standardized symbols and labels in the schematic for clarity.

2. Component Selection:

Choose components based on performance, availability, and cost considerations.

Verify the compatibility of components with the intended application and environment.

Consider sourcing and availability of components to avoid potential supply chain issues.

3. PCB Material and Stack-up:

Select appropriate materials for the PCB based on factors such as dielectric constant, thermal properties, and cost.

Determine the PCB stack-up to meet impedance requirements, signal integrity, and thermal considerations.

4. Power Distribution and Grounding:

Implement a robust power distribution network to ensure stable and reliable power delivery.

Design a low-impedance grounding system to minimize ground loops and noise.

Separate analog and digital grounds if necessary.

5. Thermal Considerations:

Consider heat dissipation and thermal management to prevent overheating.

Place components with high heat dissipation strategically on the board.

Ensure adequate spacing and ventilation for components that generate heat.

6. Design for Manufacturing (DFM):

Follow design guidelines and rules to facilitate efficient manufacturing processes.

Minimize complex or expensive manufacturing steps.

Consider assembly and testing requirements during the design phase.

7. Testing and Debugging:

Plan for test points and access for debugging during the design phase.

Include built-in self-test (BIST) features when applicable.

Consider testability of the final assembly.

8. Compliance and Standards:

Ensure compliance with industry standards and regulations relevant to the application.

Consider environmental regulations and design for compliance with RoHS, REACH, etc.

9. Mechanical Integration:

Collaborate with mechanical designers to ensure proper alignment and integration with enclosures or other mechanical components.

Consider factors such as form factor, mounting holes, and clearances.

10. Documentation:

Create comprehensive design documentation, including schematics, layout files, and bill of materials (BOM).

Provide clear and accurate information for assembly and testing.

11. Reliability and Robustness:

Design for reliability and consider factors such as component derating.

Incorporate redundancy or fail-safe mechanisms when appropriate.

By addressing these factors during the design phase, you can enhance the overall performance, reliability, and manufacturability of your printed circuit assembly. Collaboration between electrical, mechanical, and manufacturing teams is essential for a successful design.