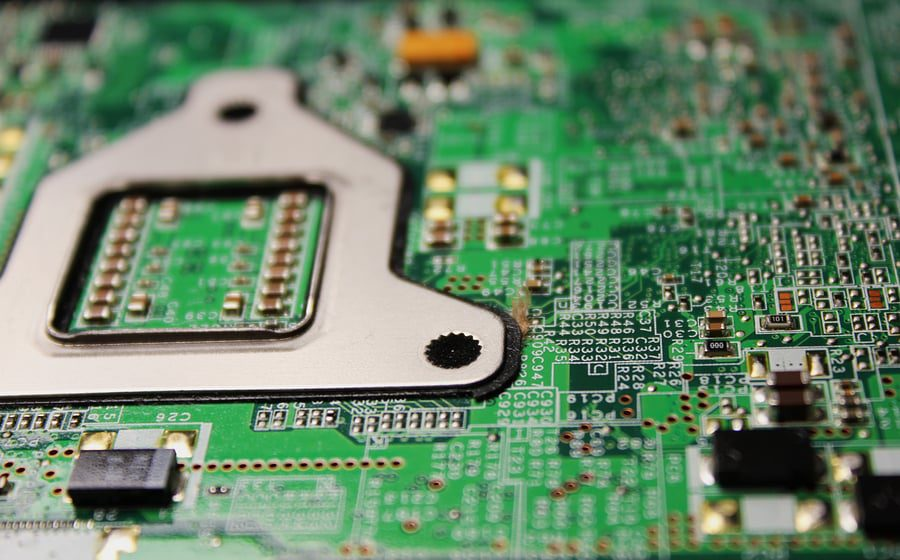

Soldering is a crucial process in the overall success of printed circuit assembly (PCA). Printed circuit boards (PCBs) are the backbone of electronic devices, and soldering is the method used to securely connect electronic components to the PCB.

Here are key roles that soldering plays in the success of printed circuit assembly:

1. Component Attachment: Soldering is used to attach electronic components, such as resistors, capacitors, integrated circuits, and other devices, to the PCB. This creates electrical connections between the components and the PCB, allowing the flow of electrical signals.

2. Electrical Connectivity: Solder acts as a conductive material, ensuring proper electrical connectivity between the components and the PCB traces. This connectivity is essential for the functionality of the electronic device.

3. Mechanical Stability: Soldering provides mechanical stability to the components on the PCB. It forms a strong bond between the component leads and the PCB pads, preventing the components from becoming loose or detached during handling, transportation, or operation.

4. Thermal Management: Solder also plays a role in thermal management. It helps to dissipate heat generated by electronic components, ensuring that the temperature of the components stays within acceptable limits. Proper soldering techniques and materials contribute to efficient heat transfer.

5. Signal Integrity: Soldering impacts the signal integrity of the electronic circuits. Proper solder joints ensure low resistance and minimal signal loss, contributing to reliable data transmission and overall performance.

6. Reliability and Durability: A well-executed soldering process contributes to the reliability and durability of the electronic assembly. Proper solder joints resist environmental factors such as temperature variations, vibrations, and humidity, ensuring the longevity of the electronic device.

7. Quality Control: Soldering quality is critical for the overall quality of the PCB assembly. Proper soldering techniques and inspection processes are employed to identify and rectify any defects, ensuring that the final product meets quality standards.

8. Miniaturization and High-Density Designs: With the trend towards miniaturization and high-density designs, precise and controlled soldering becomes even more critical. Soldering techniques, such as surface mount technology (SMT), enable the assembly of smaller and more complex electronic devices.

In summary, soldering is a fundamental process in printed circuit assembly, providing electrical, mechanical, and thermal connections that are essential for the functionality, reliability, and longevity of electronic devices.