Printed Circuit Assembly (PCA) is a crucial aspect of modern electronics manufacturing, encompassing various processes and technologies to bring electronic devices to life. This article will delve into the key components and processes associated with Printed Circuit Assembly, shedding light on the intricate world of PCB fabrication and assembly.

1. Printed Circuit Assembly Overview:

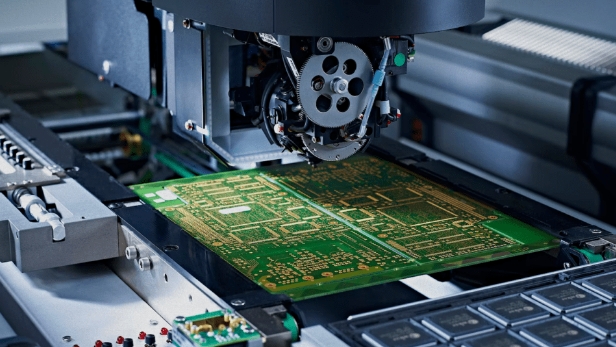

Printed Circuit Assembly, often referred to as PCB assembly, is the process of populating a printed circuit board (PCB) with electronic components to create a functional electronic device. This comprehensive process involves various technologies and steps to ensure the precise assembly of components on the PCB.

PCB fabrication is the initial step in Printed Circuit Assembly. The process involves designing the PCB layout, followed by the manufacturing of the actual circuit board. Keywords such as PCB design, component placement, and PCB layout play a pivotal role in this phase.

3. Surface Mount Technology (SMT) Assembly:

SMT assembly is a prevalent technology in Printed Circuit Assembly. It involves mounting electronic components directly onto the surface of the PCB, eliminating the need for leads or holes. The use of SMT contributes to the miniaturization of electronic devices.

4. Through-Hole Assembly:

In contrast to SMT, Through-Hole Assembly involves mounting components with wire leads through holes in the PCB. This traditional method is still relevant for certain applications, and keywords like through-hole assembly and soldering are significant in this context.

5. Electronic Components:

Understanding electronic components is crucial in Printed Circuit Assembly. Components such as resistors, capacitors, and integrated circuits are integral parts of the assembly process. Knowledge of pick and place, a process involving the automated placement of components, is essential.

6. PCB Testing and Inspection:

After assembly, PCBs undergo rigorous testing and inspection processes to ensure functionality and quality. Keywords like PCB testing, inspection, and reflow soldering (a process involving the controlled melting and solidification of solder) are critical in this phase.

Conclusion:

Printed Circuit Assembly is a complex and intricate process that plays a vital role in the production of electronic devices. Whether it's the design and fabrication of the PCB or the precise assembly of electronic components using advanced technologies like SMT, every step contributes to the functionality and reliability of the final product. As electronic devices continue to evolve, Printed Circuit Assembly remains at the forefront of innovation, driving advancements in the electronics manufacturing industry.