If you are interested in electronics, you may have come across the term CCA, which stands for Circuit Card Assembly. But what exactly is a CCA and how is it different from a PCB or a PCBA? In this article, we will explain what a CCA is, what components it consists of, what types of CCA exist, and how it differs from a PCB or a PCBA.

A CCA is a thin, flat piece of dielectric material, usually fiberglass, with conductive traces or paths etched on it. These traces connect various electronic components, such as resistors, capacitors, integrated circuits, etc., that are soldered on the board. A CCA is also known as a printed circuit board (PCB) or a printed wiring board (PWB).

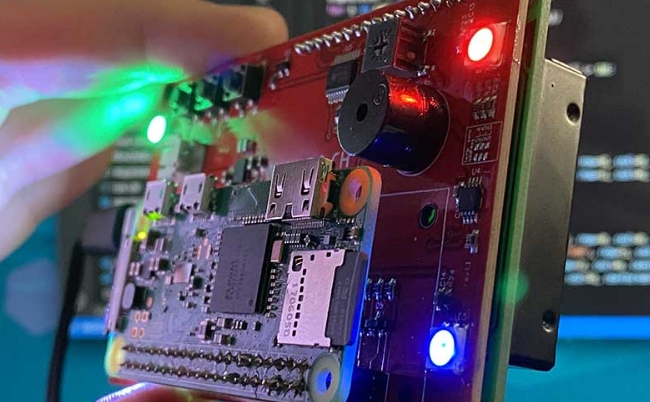

A CCA transforms a bare circuit board into a functional unit by soldering electrical and electronic components on the board. A CCA is applicable in several home appliances, such as televisions, smartphones, and electronic gadgets. It is also applicable in many industries, such as navigation systems, medical imaging systems, monitors, and automobile displays.

A CCA consists of four main components: substrate, copper, solder mask, and silkscreen. Let's discuss them in detail.

1.Substrate: The substrate is the base material of the CCA that provides mechanical support and insulation for the components. The substrate is usually made of fiberglass, which is durable and heat-resistant. Depending on the application and design of the CCA, the substrate can be rigid, flexible, rigid-flex, or metal core.

2.Copper: Copper is the conductive material that forms the traces or paths on the substrate. Copper connects the electronic components and allows the flow of electric current. Copper can be laminated on one or both sides of the substrate or in multiple layers for complex designs. The thickness of the copper layer determines the current carrying capacity of the CCA.

3. Solder mask: The solder mask is the greenish layer that covers most of the surface of the CCA. The solder mask protects the copper traces from corrosion and prevents short circuits between adjacent traces. The solder mask also provides contrast for identifying components and traces on the board.

3. Silkscreen: The silkscreen is the white layer that contains text and symbols on the CCA. The silkscreen helps to identify components, pins, polarities, test points, etc., on the board. The silkscreen also adds aesthetic value to the CCA.

There are different types of CCA based on their design and complexity. Some of the common types are:

1.Single-sided CCA: A single-sided CCA has copper traces and components on one side of the substrate only. This type of CCA is simple and inexpensive to manufacture but has limited functionality and density.

2.Double-sided CCA: A double-sided CCA has copper traces and components on both sides of the substrate. This type of CCA can accommodate more components and interconnections than a single-sided CCA but requires through-hole vias or plated holes to connect the traces on both sides.

3.Multilayer CCA: A multilayer CCA has more than two layers of copper traces sandwiched between layers of substrate. This type of CCA can achieve high functionality and density by using multiple layers of interconnections and vias. However, this type of CCA is more expensive and difficult to manufacture than single-sided or double-sided CCAs.

CCA and PCBA are often used interchangeably to refer to an assembled circuit board with components. However, there is a subtle difference between them.

CCA stands forCircuit Card Assembly, which implies that the circuit board is assembled with components but not necessarily tested or verified for functionality.

PCBA stands for Printed Circuit Board Assembly or Printed Circuit Assembly, which implies that the circuit board is not only assembled with components but also tested and verified for functionality.

Therefore, a PCBA is a more complete product than a CCA.

Conclusion

CCA is an acronym for Circuit Card Assembly, which is a thin, flat piece of dielectric material with conductive traces and electronic components soldered on it. A CCA consists of four main components: substrate, copper, solder mask, and silkscreen. There are different types of CCA based on their design and complexity: single-sided, double-sided, and multilayer. A CCA differs from a PCBA in that a PCBA is tested and verified for functionality while a CCA may not be.