PCB circuit board design is the process of creating a physical layout of an electronic circuit on a printed circuit board (PCB). PCBs are thin boards made of fiberglass, copper, and other materials that can hold and connect various electronic components, such as resistors, capacitors, transistors, and integrated circuits. PCBs are widely used in various applications, such as computers, smartphones, medical devices, automotive systems, and aerospace equipment.

In this article, we will introduce the basic steps and tools for PCB circuit board design, as well as some tips and best practices to help you get started. We will also explain the difference between PCB and PCBA, two terms that are often confused or used interchangeably.

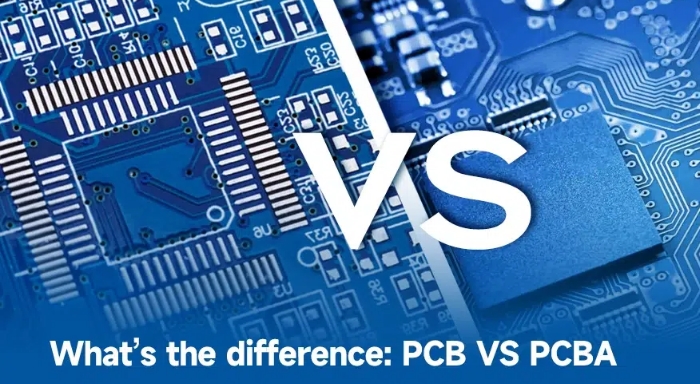

Before we dive into the steps of PCB circuit board design, let's clarify the difference between PCB and PCBA. According to EMSG Inc., the main difference between these two terms is that **PCB refers to a blank circuitry board**, while **PCBA refers to a board that contains all of the necessary electronic components for the board to function as needed**. A PCB is not yet functional because it does not have the required components in place, while a PCBA is a complete and functional board.

PCBs and PCBAs are two different parts of the same process — a PCBA is built on top of an existing PCB. The process of attaching components to a PCB is called PCB assembly or PCBA for short. Therefore, “PCB design”refers to the process of creating the layout of the traces and pads on a PCB, while“PCB assembly”refers to the process of soldering or mounting components onto a PCB.

Step 1: Schematic Capture

The first step of PCB circuit board design is to create a schematic diagram of your circuit. A schematic diagram is a graphical representation of the components and connections in your circuit, using standardized symbols and notations. A schematic diagram helps you to visualize the functionality and logic of your circuit, as well as to identify any errors or inconsistencies before moving on to the next step.

There are many software tools available for schematic capture, such as EasyEDA, Flux, Altium Designer, and KiCad. These tools allow you to drag and drop components from libraries, draw wires and buses, add labels and annotations, and export your schematic as an image or a file format that can be imported by other tools.

Step 2: Create a Blank PCB Layout

The next step of PCB circuit board design is to create a blank PCB layout based on your schematic diagram. A PCB layout is a two-dimensional representation of the physical dimensions and shapes of your PCB and its components. A PCB layout also shows the layers of copper traces, vias, pads, holes, and other features that will be etched or drilled on your PCB.

To create a blank PCB layout, you need to choose the size and shape of your board, the number and thickness of layers, the type and color of solder mask and silkscreen, and other parameters. You can use the same software tools as in step 1 for this purpose, or you can use dedicated PCB layout tools, such as Eagle, OrCAD, or PADS. These tools allow you to import your schematic file, define your board outline and layers, set up design rules and constraints, and generate a netlist that links your components to their corresponding pads and traces.

Step 3: Place Components and Route Traces

The third step of PCB circuit board design is to place your components on your PCB layout and route the traces between them. This is the most challenging and time-consuming step of the process, as it requires careful planning and optimization to achieve the best performance, reliability, and manufacturability of your PCB.

Component placement involves deciding where to position each component on your board, taking into account factors such as electrical noise, heat dissipation, signal integrity, mechanical stability, accessibility, and aesthetics. You can use the software tools to drag and drop components from your netlist onto your board, rotate and flip them as needed, align them with grids or guidelines, and arrange them in groups or clusters.

Trace routing involves connecting each component to its corresponding pads and traces on your board, following the netlist generated from your schematic diagram. You can use the software tools to draw traces manually or automatically using autorouters. You can also use different routing modes (such as single-ended or differential), widths (such as narrow or wide), styles (such as straight or curved), angles (such as 45° or 90°), layers (such as top or bottom), and vias (such as through-hole or blind) to optimize your routing.

Step 4: Verify and Export Your Design

The final step of PCB circuit board design is to verify your design for any errors or issues that might affect its functionality or manufacturability. You can use the software tools to perform various checks and simulations on your design, such as electrical rule check (ERC), design rule check (DRC), signal integrity analysis (SIA), thermal analysis (TA), electromagnetic compatibility analysis (EMC), etc. These checks and simulations help you to identify and resolve any problems with your design before sending it to fabrication.

Once you are satisfied with your design, you can export it in a file format that can be read by your PCB manufacturer. The most common file format for this purpose is Gerber, which contains all the information about your board's layers, features, dimensions, colors, etc. You can also export other files that might be required by your manufacturer or assembler, such as drill files (for holes), pick-and-place files (for component placement), bill of materials (BOM) files (for component list), etc.

Conclusion

PCB circuit board design is a complex and rewarding process that involves many steps and tools. By following the basic steps and tips outlined in this article, you can create your own PCB circuit board design for your project. However, this is only an introduction to the topic, and there are many more aspects and details that you can learn and explore. We hope that this article has sparked your interest and curiosity in PCB circuit board design, and we encourage you to continue learning and practicing this skill.