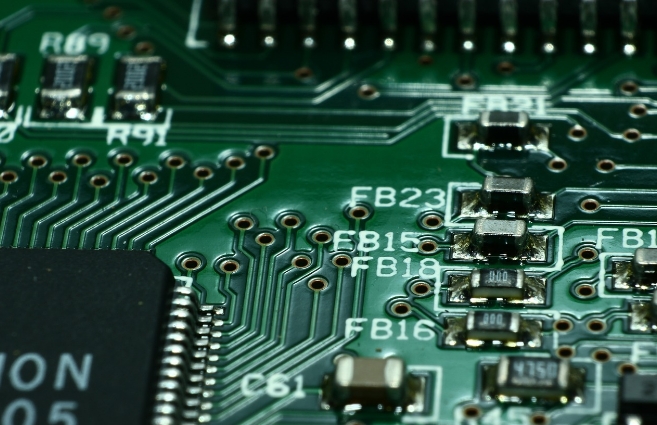

Printed Circuit Assembly (PCBA) is the process of assembling electronic components onto a printed circuit board (PCB). PCBs are essential in modern technology as they provide a solid foundation for mounting and connecting various electronic components. PCBA involves soldering components onto the PCB to create a functional electronic circuit.

PCBs are the backbone of electronic devices, enabling the seamless flow of electrical signals between components. They are used in a wide range of industries, including telecommunications, automotive, aerospace, consumer electronics, and more. PCBs play a crucial role in ensuring the proper functioning and reliability of electronic devices.

A PCB is composed of several layers, including a substrate made of fiberglass, copper traces, holes for component placement, and inner and outer layers. The components are soldered onto the PCB, and the entire board is insulated with a solder mask and held together with epoxy resin. The copper traces on the PCB carry electronic signals between components.

There are different types of PCBs available, including rigid PCBs, flexible PCBs, and metal core PCBs. Rigid PCBs are the most common and are made of a rigid substrate, typically FR-4, with copper foil layers. Flexible PCBs are made of flexible materials that can bend and are used in applications where space and weight are critical. Metal core PCBs have a base material that can dissipate heat effectively and are used in applications with heat-sensitive components.

The process of PCB assembly involves several steps to ensure the proper placement and connection of electronic components.

The first step in the assembly process is applying solder paste to the PCB. Solder paste is applied using a stencil, which is aligned with the PCB and holds the solder paste in place. The solder paste contains a mixture of tin, silver, copper, and flux. The stencil is then removed, leaving solder paste on the PCB's pads.

Once the solder paste is applied, automated pick and place machines are used to precisely place surface-mount components onto the PCB. These machines use the information from the component's X, Y coordinates to accurately position and attach the components to the correct locations on the PCB.

After the components are placed, the PCB is passed through a reflow oven. The reflow oven heats the PCB to a specific temperature, causing the solder paste to melt and form a strong bond between the components and the PCB. This process is known as reflow soldering and ensures reliable electrical connections.

To ensure the quality of the assembled PCB, thorough inspections are conducted. Automated optical inspection (AOI) machines are used to detect any potential defects, such as missing or misaligned components. Additional manual inspections may also be performed to verify the quality of the assembly.

In addition to surface-mount components, through-hole components may also be used in PCB assembly. These components have leads or wires that are inserted into pre-drilled holes on the PCB and then soldered in place. Through-hole assembly may be done manually or with the assistance of automated equipment.

Once the assembly is complete, a final inspection is conducted to ensure the PCB meets all specifications. Functional tests may also be performed to verify the proper operation of the assembled circuit.

After inspection, the PCB is cleaned to remove any flux residue or contaminants. The PCB is then finished according to the desired specifications, such as adding protective coatings or markings. Finally, the assembled PCBs are packaged and shipped to the customer.

PCB assembly can involve both through-hole and surface-mount components. Through-hole assembly involves inserting leads or wires of components into pre-drilled holes on the PCB and soldering them in place. Surface-mount assembly, on the other hand, involves placing components directly onto the PCB's surface and soldering them using solder paste and reflow soldering.

PCB assembly can be done manually or with the assistance of automated equipment. Manual assembly requires skilled technicians to place and solder components by hand. Automated assembly, on the other hand, utilizes pick and place machines and other automated equipment to precisely place and solder components, resulting in higher efficiency and accuracy.

PCB assembly can be categorized based on volume requirements. Low volume assembly is suitable for small quantities of PCBs, typically for prototypes or specialized applications. Medium volume assembly caters to moderate quantities, offering a balance between cost and production speed. High volume assembly is optimized for large-scale production, offering cost-effective solutions for mass production.

PCB assembly can be performed in-house or outsourced to specialized assembly service providers. In-house assembly provides better control over the entire manufacturing process and is suitable for companies with the necessary resources and expertise. Outsourced assembly, on the other hand, allows companies to focus on their core competencies while leveraging the expertise and capabilities of specialized assembly providers.

Before starting the PCB assembly process, careful consideration must be given to the component layout. Components with polarity, such as diodes and capacitors, must be properly oriented to ensure correct functionality. The spacing between components and holes should also be taken into account to avoid any interference or short circuits.

Proper spacing between holes and vias is crucial to ensure reliable connections and prevent short circuits. The spacing between holes and between holes and traces should be sufficient to avoid any unintended electrical connections. Sufficient clearance should also be provided around each hole to facilitate soldering and component placement.

The design of copper pads, their thickness, and trace width are important considerations in PCB assembly. Copper pads should be designed to accommodate the specific component's footprint and ensure proper solder joint formation. The thickness of copper traces should be sufficient to carry the required current, while the trace width should be optimized to minimize resistance and impedance.

The substrate of a PCB is typically made of fiberglass material, commonly known as FR-4. The substrate provides rigidity and mechanical support to the PCB. It is coated with a thin layer of copper foil, which serves as the conductive material for the traces and pads.

The copper layer on a PCB is responsible for carrying electrical signals between components. It consists of thin copper foil laminated onto the substrate. The copper layer is etched to create the desired circuit pattern, leaving behind traces and pads that connect the components.

The solder mask is a protective layer applied over the copper layer to prevent solder bridges and ensure proper soldering. It is typically green in color, but other colors such as blue or red can also be used. The silkscreen layer provides labels, component designators, and other markings on the PCB, making it easier to assemble and identify components.

Surface Mount Technology (SMT) is a mounting technique widely used in PCB assembly. SMT components are small and have no leads or wires. They are directly mounted onto the surface of the PCB using solder paste and reflow soldering. SMT technology offers several advantages, including smaller board size, higher component density, and improved electrical performance.

Through-Hole Technology (THT) is an older mounting technique that involves inserting component leads or wires into pre-drilled holes on the PCB. The leads are then soldered to the opposite side of the PCB to create a secure connection. THT components are typically larger and are used for applications requiring higher mechanical strength or power handling capabilities.

Prototype assembly is the initial stage of PCB assembly, where a small quantity of boards is produced for testing and validation. This stage allows designers to verify the functionality and performance of the PCB before proceeding with larger-scale production.

Production assembly involves the large-scale manufacturing of PCBs. It is used to meet the demand for electronic devices in various industries. Production assembly requires efficient and reliable processes to ensure consistent quality and timely delivery.

Box build and electro-mechanical assembly services involve the integration of PCBs into complete electronic systems. These services include the assembly of additional components, such as connectors, switches, displays, and other mechanical parts, to create a fully functional product.

PCB assembly services can be categorized into consignment, partially consigned, and turn-key assembly. Consignment assembly involves the customer providing all the necessary components and materials to the assembly service provider. Partially consigned assembly allows the customer to provide some components, while the assembly service provider procures the remaining components. Turn-key assembly involves the assembly service provider handling the entire process, from component procurement to final assembly and testing.

Solder paste is a crucial component in the PCB assembly process. It is a mixture of solder alloy and flux. The solder paste is applied to the PCB's pads using a stencil, and it serves as the medium for creating electrical connections between the components and the PCB. During reflow soldering, the solder paste melts and forms a strong bond, ensuring reliable electrical connections.

Components are placed on the PCB using automated pick and place machines. These machines use preprogrammed X, Y coordinates to accurately position the components on the solder paste. The machines have vacuum grippers that pick up the components and place them onto the designated pads. The accurate placement of components is essential for proper functionality and reliable solder joints.

Reflow soldering is the process of melting the solder paste to create electrical connections between the components and the PCB. During reflow soldering, the PCB is heated in a reflow oven to a specific temperature, causing the solder paste to melt and form a strong bond. This process ensures reliable and durable solder joints, contributing to the overall quality and performance of the assembled PCB.

Quality control is an integral part of the PCB assembly process. Automated optical inspection (AOI) machines are used to detect any potential defects, such as missing or misaligned components, solder bridges, or insufficient soldering. Manual inspections may also be conducted to verify the quality of the assembly. Functional tests may be performed to ensure the proper operation of the assembled circuit.

Through-hole assembly involves inserting component leads or wires into pre-drilled holes on the PCB and soldering them on the opposite side. Surface-mount assembly, on the other hand, involves directly mounting components onto the surface of the PCB using solder paste and reflow soldering. Through-hole assembly is typically used for larger components, while surface-mount assembly allows for smaller and more densely packed components.

Automated assembly offers several advantages over manual assembly. It improves efficiency and accuracy, as pick and place machines can quickly and precisely position components. Automated assembly also reduces the risk of human error, resulting in higher-quality and more reliable assemblies. Additionally, automated assembly can handle larger volumes, making it more suitable for mass production.

PCB assembly can be categorized into low volume, medium volume, and high volume options. Low volume assembly is suitable for small quantities, typically for prototyping or specialized applications. Medium volume assembly caters to moderate quantities, striking a balance between cost and production speed. High volume assembly is optimized for large-scale production, offering cost-effective solutions for mass production.

Outsourcing PCB assembly to specialized assembly service providers offers several benefits. It allows companies to focus on their core competencies and reduce manufacturing costs. Outsourcing also provides access to specialized equipment, expertise, and quality control processes. Additionally, outsourcing can streamline the supply chain and shorten lead times, ensuring timely delivery of assembled PCBs.

Controlled impedance is a technique used to maintain a specific impedance value for high-frequency signals on the PCB. It involves careful design and manufacturing processes to ensure consistent impedance throughout the traces and layers. Controlled impedance is crucial for maintaining signal integrity and minimizing signal reflections in high-speed digital and RF applications.

Stack ups and controlled dielectric techniques are used to manage signal integrity and impedance control in multilayer PCBs. By carefully selecting and arranging the layers with specific dielectric materials and thicknesses, the desired impedance can be achieved. These techniques are essential for high-speed digital and RF applications where signal integrity is critical.

Plating finishes are applied to the exposed copper surfaces of the PCB to protect them from oxidation and improve solderability. Common plating finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). The selection of the plating finish depends on factors such as cost, solderability, and environmental requirements.

Solder mask is a protective layer applied over the PCB's copper traces to prevent solder bridges and ensure proper soldering. It is typically green in color but can also be blue, red, or other colors. Scoring is a process used to create V-shaped grooves on the PCB to facilitate separation into individual boards after assembly. Scoring helps in efficient assembly and reduces the risk of damaging the PCB during separation.

Arrays and tab route techniques are used to optimize panelization and assembly efficiency. Arrays involve replicating multiple copies of the same PCB design on a single panel, maximizing production yield. Tab route refers to the use of tabs or bridges between individual PCBs during panelization. Tab route allows for easy separation of individual boards after assembly.

Obtaining an instant quote and placing an order for PCB assembly has become easier with online platforms. Customers can provide the necessary specifications, such as PCB dimensions, component types, quantities, and assembly requirements, to receive an instant quote. Upon confirmation, the order can be placed online, simplifying the ordering process.

PCB assembly pricing varies based on factors such as the complexity of the design, component types and quantities, assembly volume, and desired turn-around time. Assembly providers offer different pricing options, including competitive per-component pricing, volume-based discounts, and expedited turn-around options for urgent orders.

For PCBs with 2 or 4 layers, specific pricing options are available. These options consider the number of layers, board dimensions, and desired quantities. Customers can choose the most suitable pricing option based on their requirements.

Pricing for PCBs with aluminum clad or RF (Radio Frequency) materials is tailored to the specific requirements of these specialized materials. Aluminum clad PCBs offer superior thermal management, while RF materials are optimized for high-frequency applications. The pricing for these materials reflects their unique properties and manufacturing processes.

Printed Circuit Assembly plays a crucial role in the production of electronic devices, ensuring reliable connections and functionality. Understanding the basics of PCBs, the assembly process, and the various techniques and services available is essential for successful PCB assembly. Whether it is through-hole or surface-mount assembly, low volume or high volume production, or in-house or outsourced assembly, the choice depends on specific requirements and resources. With advanced techniques and pricing options, PCB assembly has become more accessible and efficient for a wide range of industries. By partnering with experienced assembly service providers, companies can achieve high-quality and cost-effective assembly solutions for their electronic devices.

Frequently Asked Questions about Printed Circuit Assembly

What are the common soldering defects in PCB assembly?

Solder Bridges: When solder creates unintended connections between two adjacent pads or traces.

Insufficient Solder: When there is not enough solder to form a proper connection between the component and the pad.

Tombstoning: When a component lifts and stands on one end during reflow soldering, resembling a tombstone.

Cold Solder Joints: When the solder joint does not form a strong bond due to inadequate heat or incorrect soldering technique.

How can I ensure the quality of PCB assembly?

Perform regular inspections and quality control checks throughout the assembly process.

Use automated optical inspection (AOI) machines to detect defects and ensure proper component placement.

Conduct functional tests to verify the functionality of the assembled circuit.

Follow industry standards and guidelines for soldering, component placement, and inspection.

What are the advantages of surface-mount technology (SMT) over through-hole technology (THT)?

Smaller Component Size: SMT components are smaller and allow for higher component density on the PCB.

Improved Electrical Performance: SMT components offer better high-frequency performance and signal integrity.

Cost-Effective: SMT assembly is generally more cost-effective due to reduced component and manufacturing costs.

Automation-Friendly: SMT components can be easily handled and placed by automated pick and place machines.

Can I assemble my PCBs manually instead of using automated equipment?

Manual assembly is possible for small-scale production or prototypes.

However, manual assembly is time-consuming, prone to errors, and less efficient compared to automated assembly.

Automated pick and place machines ensure precise component placement and higher productivity.

What are the key factors to consider when choosing a PCB assembly service provider?

Experience and Expertise: Look for providers with a proven track record in PCB assembly.

Quality Control Measures: Ensure the provider has robust quality control processes in place.

Flexibility and Scalability: Consider the provider's ability to handle different assembly volumes and adapt to changing needs.

Cost and Pricing Options: Evaluate pricing structures and options to find the most cost-effective solution.

Communication and Support: Check if the provider offers responsive customer support and clear communication channels.

By understanding the fundamentals of printed circuit assembly and leveraging the expertise of assembly service providers, companies can ensure the successful production of high-quality electronic devices.