If you are looking for a flexible printed circuit board (PCB) manufacturer, you might be overwhelmed by the number of options available in the market. Flex PCBs are widely used in various applications, such as wearable devices, medical equipment, aerospace, automotive, and more. They offer many advantages over rigid PCBs, such as reduced weight, increased reliability, improved performance, and design flexibility.

However, not all flex PCB manufacturers are created equal. Some may have better quality, service, delivery time, or price than others. How can you find the best one for your project? Here are some factors to consider when choosing a flex PCB manufacturer:

1.Experience and expertise: You want to work with a manufacturer that has a proven track record of producing high-quality flex PCBs for different industries and applications. They should have the necessary skills and knowledge to handle your specific requirements and challenges. You can check their portfolio, testimonials, certifications, and awards to verify their experience and expertise.

2.Capabilities and facilities: You want to work with a manufacturer that has the latest equipment and technology to produce your flex PCBs. They should be able to handle various types of flex PCBs, such as single-sided, double-sided, multilayer, rigid-flex, etc. They should also be able to offer different services, such as design, prototyping, testing, assembly, etc. You can check their capabilities and facilities by visiting their website or asking for a tour.

3.Quality and reliability: You want to work with a manufacturer that delivers consistent and reliable quality for your flex PCBs. They should have a strict quality control system and follow the industry standards and regulations. They should also have a low defect rate and a high customer satisfaction rate. You can check their quality and reliability by asking for samples, references, or reviews.

4.Delivery time and cost: You want to work with a manufacturer that can deliver your flex PCBs on time and within your budget. They should have a fast turnaround time and a flexible production schedule. They should also have a competitive pricing structure and offer discounts or incentives for bulk orders. You can check their delivery time and cost by requesting a quote or comparing different options.

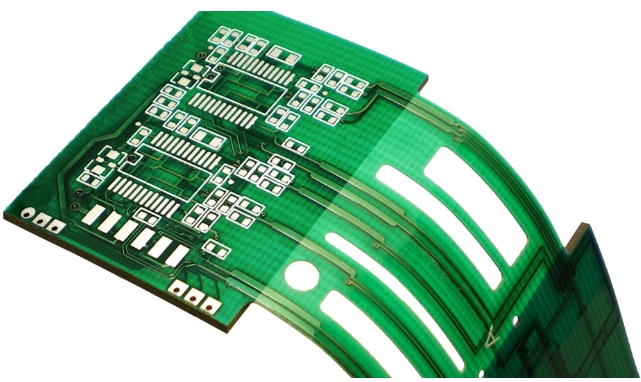

One of the types of flex PCBs that you may encounter is the rigid-flex PCB. This is a hybrid of rigid and flexible PCBs that combines the best of both worlds. Rigid-flex PCBs have rigid sections that provide stability and support for components, and flexible sections that allow bending and folding. Rigid-flex PCBs are ideal for applications that require complex shapes, high-density wiring, or frequent movement. They can also reduce the number of connectors and cables needed, which can improve reliability and performance.

1.Wearable devices: Rigid-flex PCBs can fit into small spaces and conform to different shapes, making them suitable for wearable devices such as smartwatches, fitness trackers, or health monitors.

2.Medical equipment: Rigid-flex PCBs can withstand harsh environments and vibrations, making them suitable for medical equipment such as pacemakers, defibrillators, or surgical instruments.

3.Aerospace: Rigid-flex PCBs can handle high temperatures and pressures, making them suitable for aerospace applications such as satellites, rockets, or drones.

4.Automotive: Rigid-flex PCBs can reduce the weight and size of components, making them suitable for automotive applications such as navigation systems, cameras, or sensors.

There is no definitive answer to this question, as it depends on various factors such as your design specifications, budget constraints, performance requirements, etc. However, here are some general guidelines that can help you decide:

- If your project requires a simple shape and minimal wiring density, you may opt for a single-sided or double-sided flex PCB.

- If your project requires a complex shape or high wiring density, you may opt for a multilayer flex PCB.

- If your project requires both stability and flexibility in different areas of the board, you may opt for a rigid-flex PCB.

- If your project requires high reliability and durability in harsh environments or frequent movement, you may opt for a rigid-flex PCB.

Choosing the right flex PCB manufacturer can make a big difference in the success of your project. By considering these factors, you can find the best one for your needs. If you are looking for a reliable and professional flex PCB manufacturer, look no further than FlexPCB.com. We have over 20 years of experience in producing high-quality flex PCBs for various industries and applications. We have the latest equipment and technology to handle any type of flex PCB project. We have a strict quality control system and follow the ISO 9001:2015 standard. We have a fast turnaround time and a competitive pricing structure. Contact us today for a free quote or consultation.