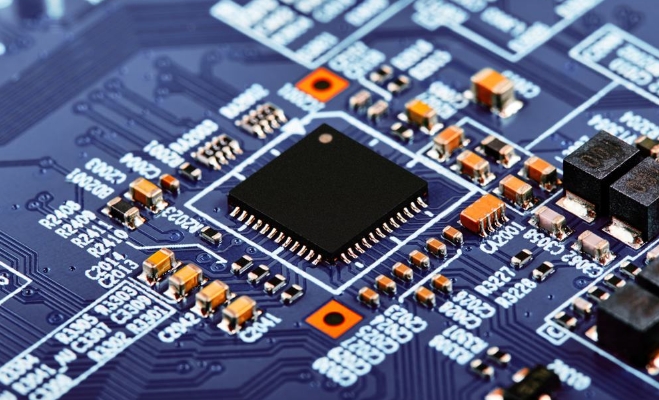

Prototype printed circuit board (PCB) assembly plays a crucial role in the product development process, enabling engineers and designers to test and validate their designs before committing to mass production. This article provides a comprehensive overview of prototype PCB assembly, including its benefits, types, and key considerations for customers.

Design Verification: Prototype assembly allows for thorough testing and verification of the PCB design, ensuring that it meets functional and performance requirements.

Early Detection of Errors: Building a prototype PCB helps identify and correct design flaws, component issues, and assembly errors early in the development cycle, preventing costly rework or redesign.

Design Optimization: Prototyping enables engineers to experiment with different component configurations and layouts, optimizing the design for manufacturability and performance.

Time-to-Market Advantage: By identifying and resolving issues during the prototyping phase, companies can accelerate their time-to-market, gaining a competitive edge.

In-House Prototyping: Companies with the necessary expertise and equipment can perform prototype PCB assembly in-house, maintaining control over the process and reducing lead times.

Outsourcing to Prototype Assembly Services: Many companies choose to outsource prototype PCB assembly to specialized service providers, leveraging their expertise, advanced equipment, and rapid turnaround times.

Quality and Reliability: Customers expect prototype PCBs to be assembled with the utmost precision and attention to detail, ensuring the highest levels of quality and reliability.

Rapid Turnaround: Time is of the essence in product development, and customers often require fast turnaround times for prototype PCB assembly to meet their project timelines.

Cost-Effectiveness: Customers are interested in cost-effective prototype PCB assembly services that provide value for money without compromising on quality.

Flexibility and Customization: Customers may have specific requirements for their prototype PCBs, such as unique component selection, specialized testing, or adherence to industry standards. They seek suppliers who can accommodate these customization needs.

Intellectual Property (IP) Protection: Customers are concerned about protecting their intellectual property during the prototype PCB assembly process. They look for suppliers who prioritize confidentiality and have robust IP protection measures in place.

Prototype printed circuit board assembly is an essential step in the product development process, enabling companies to validate designs, optimize performance, and accelerate time-to-market. By understanding the benefits, types, and customer considerations related to prototype PCB assembly, companies can make informed decisions when selecting suppliers and ensure successful project outcomes. As technology continues to advance, prototype PCB assembly services will continue to evolve, offering even faster turnaround times, higher levels of precision, and enhanced customization options to meet the ever-changing needs of customers.