PCB stands for printed circuit board. In the aerospace industry, PCBs are essential components used in various electronic systems and devices on aircraft, satellites, missiles, and other aerospace vehicles. PCBs provide a structured and reliable platform for mounting and interconnecting electronic components, enabling them to communicate and function as a cohesive system.

PCBs in aerospace applications are typically designed and manufactured to meet stringent requirements for performance, reliability, and environmental resilience. They are often subjected to harsh conditions, including extreme temperatures, vibration, shock, and radiation. As a result, aerospace PCBs are typically made using high-quality materials and advanced manufacturing techniques to ensure they can withstand these demanding environments.

Aerospace PCBs find application in a wide range of systems and subsystems, including:

Flight control systems

Avionics systems

Navigation and guidance systems

Communication systems

Radar systems

Missile guidance systems

Satellite control systems

Spacecraft instrumentation

PCBs in aerospace applications play a critical role in ensuring the safety, reliability, and performance of these systems. They provide a compact and lightweight means of integrating complex electronic circuitry, enabling efficient and effective operation of aerospace vehicles.

Some key considerations for PCBs in aerospace applications include:

High reliability and quality: Aerospace PCBs must meet stringent quality and reliability standards to ensure they can withstand harsh operating conditions and perform consistently over a long service life.

Environmental resilience: Aerospace PCBs must be able to withstand extreme temperatures, vibration, shock, and radiation. They are often coated or treated with specialized materials to protect them from harsh environments.

Size and weight optimization: Aerospace systems are often constrained by space and weight limitations. PCBs are designed to be compact and lightweight to minimize the overall weight of the system.

Advanced technologies and materials: Aerospace PCBs often utilize cutting-edge technologies and specialized materials to achieve high performance and reliability. These may include high-frequency laminates, high-density interconnect (HDI) technologies, and exotic metals for enhanced electrical and thermal performance.

Overall, PCBs in aerospace applications are critical components that play a vital role in ensuring the safety, reliability, and performance of electronic systems on aircraft, satellites, and other aerospace vehicles.

PCB assembly manufacturing for aerospace presents several unique challenges that must be carefully addressed. These include:

Extreme Environments: Aerospace PCBs operate in harsh and unpredictable conditions, such as extreme temperatures, vibration, and radiation. The assembly process must ensure that components can withstand these extreme conditions without compromising performance or safety.

High-Reliability Requirements: Aerospace PCBs are mission-critical components that demand the highest levels of reliability. Failures can have catastrophic consequences, making rigorous quality control and testing procedures essential.

Miniaturization and Weight Reduction: Aerospace PCBs are often constrained by space and weight limitations. Manufacturers must employ advanced assembly techniques and select lightweight materials to achieve optimal performance without compromising size or weight.

Advanced Technologies and Materials: Aerospace PCBs utilize cutting-edge technologies and specialized materials to meet stringent performance requirements. These include high-frequency laminates, high-density interconnect (HDI) technologies, and exotic metals for enhanced electrical and thermal performance.

The manufacturing process for aerospace PCBs involves several critical steps:

Component Selection: Components are carefully selected based on their performance, reliability, and suitability for aerospace applications. Stringent quality control measures ensure that only the highest-grade components are used.

PCB Design and Layout: Aerospace PCBs require meticulous design and layout to optimize signal integrity, minimize noise, and accommodate unique form factors. Advanced design software and simulation tools are employed to ensure optimal performance.

PCB Fabrication: The PCB is manufactured using specialized processes to achieve precise dimensions, tight tolerances, and reliable electrical connectivity. Multilayer boards, flexible circuits, and rigid-flex PCBs are commonly used in aerospace applications.

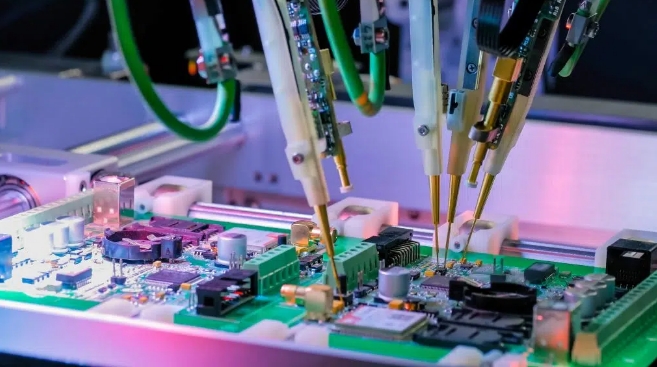

Soldering and Assembly: Soldering and assembly are critical processes that require precision and attention to detail. Automated and semi-automated assembly lines are often employed to ensure consistent and reliable assembly.

Testing and Inspection: Rigorous testing and inspection procedures are conducted throughout the manufacturing process to identify and rectify any defects or non-conformances. Advanced testing equipment and techniques are used to evaluate electrical performance, environmental resilience, and overall reliability.

PCB assembly manufacturing for aerospace is a highly specialized field that demands unwavering precision, reliability, and innovation. By addressing the unique challenges of aerospace applications, manufacturers can produce high-quality PCBs that meet the stringent requirements of this demanding industry. These PCBs play a vital role in ensuring the safety, performance, and longevity of aircraft, satellites, and other aerospace systems, enabling them to navigate the skies with confidence and reliability.