In the ever-evolving world of electronics, innovations are constantly being made to improve performance and efficiency. One such development is the thick copper printed circuit board (PCB). With its cutting-edge technology and specialized manufacturing processes, thick copper PCBs are transforming the way power is distributed within electronic devices. In this article, we will delve deep into the realm of thick copper PCBs, exploring their benefits, manufacturing techniques, and the impact they have on power distribution.

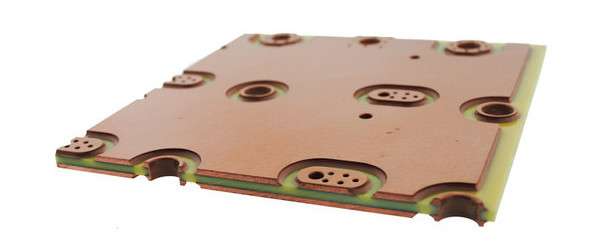

A Thick Copper PCB, also known as a Heavy Copper PCB, is a printed circuit board that features significantly thicker copper layers compared to conventional PCBs. While standard PCBs typically have copper layers ranging from 1oz to 2oz, thick copper PCBs can have copper layers as thick as 12oz or even more. This increased copper weight makes them ideal for applications that require high power distribution and superior heat dissipation.

In a PCB, copper layers act as conductive pathways that connect different components. The copper layers are etched and connected through traces, forming the required circuitry. In thick copper PCBs, the copper layers themselves are thicker, allowing for efficient flow of high current throughout the board.

Copper traces are the narrow pathways on a PCB that carry electrical signals. The thickness of the copper trace affects the trace width, which in turn impacts the amount of current the trace can carry without overheating. Thick copper PCBs have wider traces, enabling them to handle higher currents with minimal resistance and heat build-up.

In high-power electronic devices, heat dissipation is a significant concern. Thick copper PCBs excel in heat management as their increased copper weight efficiently transfers heat away from hotspots, minimizing the risk of overheating. This property makes thick copper PCBs highly desirable for power-hungry applications such as power inverters, motor controllers, and industrial automation systems.

The carrying capacity of a PCB refers to its ability to handle high electrical currents without significant voltage drops. Thick copper PCBs can accommodate substantial current flow due to their wider traces and low resistance properties. By minimizing voltage drops, these PCBs ensure efficient power distribution across the circuit, enhancing overall system performance and reliability.

With advancements in technology, devices requiring high power have become increasingly common. Thick copper PCBs provide the necessary infrastructure to meet the demands of modern-day electronics. From electric vehicles to data centers, thick copper PCBs play a pivotal role in enabling the safe and efficient operation of power-hungry devices.

To manufacture thick copper PCBs, specialized etching and plating techniques are employed to ensure precision and reliability.

The etching process in thick copper PCB manufacturing involves selectively removing excess copper from the board surface to create the desired circuitry. As thick copper PCBs have thicker copper layers, the etching process requires robust chemicals and etchants to achieve precise trace widths and maintain the desired copper thickness.

Plated through holes (PTH) are an integral part of thick copper PCBs. These holes are used for interconnection between different layers and are specially designed to handle high currents. When manufacturing thick copper PCBs, the PTH walls go through additional copper plating processes to match the desired copper thickness and ensure reliable power interconnects throughout the board.

When designing a thick copper PCB, several factors need to be taken into consideration to ensure optimal performance and reliability.

The trace width in a PCB determines its current carrying capacity. For thick copper PCBs, wider traces are necessary to accommodate higher currents. Designers must carefully calculate the trace width based on the desired current and ensure that the copper thickness is suitable for the required carrying capacity. Failure to choose the appropriate trace width and copper thickness can lead to overheating and electrical malfunction.

In certain applications where power distribution is critical, double-sided PCBs can provide additional connectivity options. Double-sided PCBs have copper traces on both sides of the board, enabling multiple power and ground planes. This arrangement enhances the current-carrying capacity and allows for more efficient power distribution throughout the circuit.

The outer layers of a thick copper PCB play a crucial role in heat dissipation. By carefully designing the layout of the outer layers, heat can be evenly distributed across the board, preventing localized hotspots. Additionally, the use of thermal vias can further enhance heat dissipation by transferring heat to inner layers or external heat sinks.

Manufacturing thick copper PCBs requires specialized equipment and techniques to ensure precision and reliability.

Heavy copper PCB manufacturing requires specialized equipment capable of handling larger copper weights during the etching and plating processes. These machines are designed to provide accurate and consistent results, ensuring that the desired copper thickness and trace widths are achieved.

Manufacturing thick copper PCBs involves using advanced techniques to deposit and etch thicker copper layers. Electroplating is often employed to build up the copper thickness, while advanced etching processes remove excess copper and define the desired circuitry. These techniques ensure that the final product meets the required specifications and can withstand high power applications.

Heat dissipation is a critical consideration in electronic devices. Thick copper PCBs excel in heat management due to their increased copper weight and conductivity.

Heavy copper PCBs effectively dissipate heat generated by high-power components, preventing temperature-related issues. The additional copper weight acts as a heat sink, drawing heat away from sensitive components and spreading it across the board. This reduces the risk of thermal damage and ensures optimal performance and longevity of the device.

The wider traces on a thick copper PCB not only improve current-carrying capacity but also aid in heat dissipation. The increased surface area of the copper traces allows for better thermal transfer, efficiently spreading heat across the board. This feature is especially valuable in applications where temperature regulation is crucial, such as power electronics and LED lighting systems.

Thick copper PCBs offer several advantages over conventional PCBs, making them an attractive choice for high-power applications.

The enhanced current-carrying capacity and superior heat dissipation capabilities of thick copper PCBs result in improved overall performance and reliability of electronic devices. With reduced voltage drops, efficient power distribution, and minimal overheating, thick copper PCBs ensure optimal functioning of power-dependent systems.

Thick copper PCBs allow engineers to design more compact and space-efficient electronic devices. With the ability to handle higher currents, designers can create smaller PCBs without sacrificing performance. This feature is particularly valuable in applications where size and weight constraints are essential, such as portable electronics and aerospace systems.

Thick copper PCBs find applications in various industries where high power distribution and heat dissipation are paramount.

Industrial equipment, including motor drives, inverters, and power supplies, often requires reliable power distribution and efficient heat dissipation. Thick copper PCBs are indispensable in such applications, ensuring safe and consistent operation in demanding industrial environments.

As the automotive industry embraces electrification and advances in autonomous vehicles, the demand for high-power electronics continues to grow. Thick copper PCBs are used in electric vehicle powertrains, onboard charging systems, and advanced driver-assistance systems, providing robust electrical connections and optimal heat management.

The renewable energy sector, with its emphasis on solar and wind power generation, relies on high-power electronics for efficient energy conversion. Thick copper PCBs are utilized in solar inverters, wind turbine converters, and grid connection systems to handle substantial currents and ensure long-term reliability in demanding environmental conditions.

In a standard PCB, the copper layers are typically thinner, ranging from 1oz to 2oz. Thick copper PCBs have significantly thicker copper layers, often exceeding 2oz. The increased copper weight allows for better power distribution and improved heat dissipation in high-power applications.

While thick copper PCBs offer numerous benefits, their use can come with limitations. Their increased copper weight may require adjusted manufacturing processes and specialized equipment. Additionally, the cost of manufacturing thick copper PCBs can be higher compared to standard PCBs.

Yes, thick copper can be incorporated into flexible circuits. However, the flexibility of the circuit may be affected due to the thickness of the copper layers. Careful consideration must be given to the specific application and the required flexibility before utilizing thick copper in flexible circuits.

Manufacturing thick copper PCBs presents challenges such as precise copper thickness control, ensuring consistent trace widths, and handling thicker copper layers during the etching and plating processes. Specialized equipment and advanced techniques are required to overcome these challenges.

While the assembly process for thick copper PCBs is similar to standard PCBs, the increased copper weight may require adjustments during the design and assembly stages. It is crucial to consider the mechanical support and connector options to accommodate the higher copper masses.