In this article, we will explore the key aspects of power supply PCB boards and how they contribute to efficient and reliable power distribution. We'll delve into the importance of PCB design, choosing the right components, optimizing heat dissipation, and more. So, whether you're a seasoned professional or a technology enthusiast, join us on this journey to discover the inner workings of power supply PCB boards.

In our increasingly connected and technologically-driven world, power supply PCB boards play a pivotal role. These compact yet sophisticated devices provide the necessary voltage and current to power a wide range of electronic systems, from smartphones to industrial machinery. Understanding the intricacies of power supply PCB boards is crucial for engineers, technicians, and enthusiasts alike.

In this article, we will dive deep into the various aspects of power supply PCB boards, focusing on their design, component selection, heat dissipation, and reliability. Whether you're building a power supply PCB for a personal project or an industrial application, this comprehensive guide will equip you with the knowledge needed to make informed decisions and create efficient and reliable power systems.

Power supply PCB boards, also known as power distribution boards or power delivery boards, are electronic circuits designed to regulate and distribute electrical power to various components of a system. These boards serve as a crucial intermediary between the main power source and the electronic devices they power. By providing the necessary voltage levels and current capacities, power supply PCB boards ensure stable and sufficient power delivery.

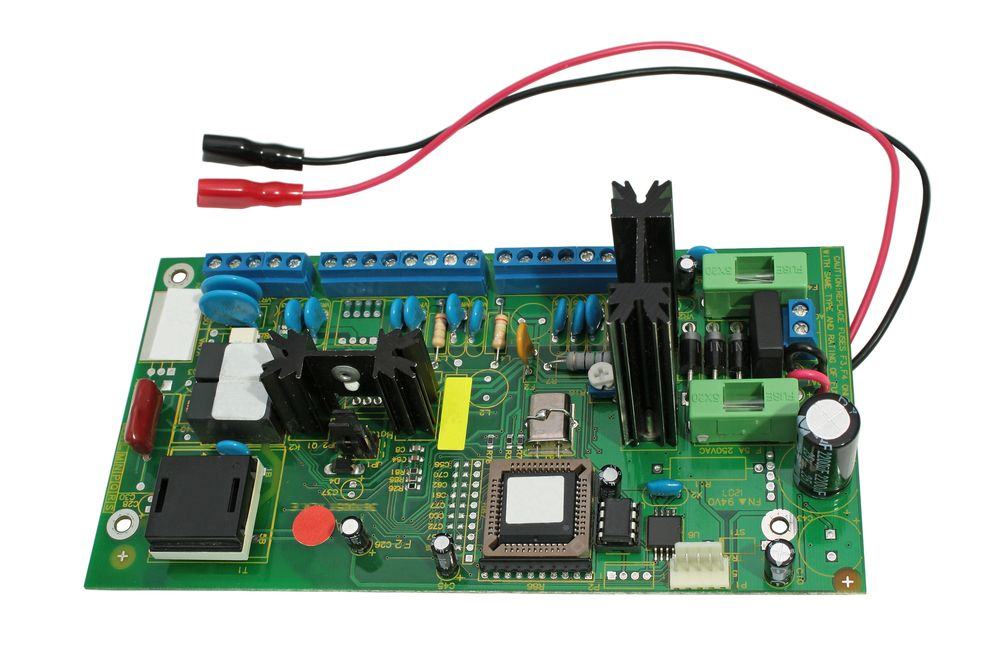

A typical power supply PCB consists of several key components working together harmoniously. These include voltage regulators, capacitors, inductors, transformers, rectifiers, and often specialized integrated circuits (ICs) tailored for power management purposes.

The voltage regulator is a crucial component responsible for maintaining a consistent output voltage despite fluctuations in the input voltage or current. Capacitors store electrical energy and help minimize voltage fluctuations, ensuring smooth power delivery. Inductors and transformers, on the other hand, enable efficient voltage step-up or step-down, depending on the system's requirements.

Designing a power supply PCB requires meticulous planning and attention to detail. Various factors come into play, such as the physical size constraints, the desired power output, and the specific environmental conditions the board will operate under. To ensure optimal performance and reliability, it is essential to consider the following aspects during the design phase:

Component placement and routing: Careful placement and efficient routing of components minimize signal interference, reduce electrical noise, and optimize the thermal characteristics of the board.

Noise and interference suppression: Power supply PCBs should incorporate techniques to minimize electromagnetic interference (EMI) and radio frequency interference (RFI) to avoid compromising the performance of the powered electronic devices.

Power plane designs: Clever implementation of power planes helps distribute power evenly across the board, preventing voltage drops and minimizing interference between power domains.

Thermal management: Efficient heat dissipation is an integral part of power supply PCB design, as excessive heat can significantly affect the performance and reliability of the components.

By paying attention to these design considerations, engineers can create power supply PCB boards that offer both efficiency and reliability, meeting the specific requirements of their applications.

Selecting the most suitable components is crucial when designing a power supply PCB. Each component plays a vital role in ensuring optimal performance, durability, and efficiency. Let's explore some key components commonly found on power supply PCBs.

Voltage regulators are critical components that maintain a stable output voltage, regardless of input voltage fluctuations or load changes. They convert the input voltage to the desired output voltage level and are available in linear or switching types.

Linear voltage regulators are simple and cost-effective but can generate significant heat due to their inherent design. On the other hand, switching voltage regulators offer higher efficiency, but they tend to be more complex to design and implement. The choice between the two depends on factors such as the level of thermal management required, cost considerations, and efficiency requirements.

When selecting voltage regulators for your power supply PCB, you must carefully assess the desired output voltage, current capabilities, efficiency, and thermal characteristics. Accuracy, ripple rejection, and load regulation are also essential parameters to consider.

Capacitors are essential components used for energy storage and filtering in power supply PCBs. They help regulate voltage ripple and noise, ensuring stable and clean power delivery to the supported electronic devices. The choice of capacitors depends on various factors such as capacitance value, voltage rating, ESR (Equivalent Series Resistance), and ESL (Equivalent Series Inductance).

Electrolytic capacitors are commonly used for their high capacitance values, but they might have higher ESR and limited lifetime. Ceramic capacitors, on the other hand, offer lower ESR and ESL, making them suitable for high-frequency filtering and decoupling applications. Selecting the right capacitor types and values for specific sections of the power supply PCB is crucial to achieving optimal performance.

Inductors play a key role in power supply PCBs, particularly in switching power supply designs. They store energy in a magnetic field and release it when the current changes. This enables voltage step-up or step-down operations, essential for converting power efficiently. Inductors need to be carefully selected based on parameters such as inductance value, DC resistance, saturation current, and operating frequency.

For higher current applications or where size constraints are critical, surface mount power inductors are commonly used. These inductors offer high efficiency, low magnetic leakage, and compact form factors. Ferrite core materials are often employed due to their excellent magnetic properties and low losses. It is crucial to choose inductors that can handle the required current ratings while avoiding saturation to ensure reliable power delivery.

Transformers, like inductors, enable voltage transformation in power supply PCB designs. They consist of two sets of wire windings, the primary and secondary, which are magnetically coupled. Transformers are widely used in both AC and DC power supply PCBs for isolation, voltage conversion, and impedance matching purposes.

When selecting transformers for power supply PCBs, considerations should be given to parameters such as turn ratios, power ratings, operating frequency, and core materials. Proper transformer selection ensures efficient power conversion and delivery while minimizing losses and electromagnetic interference.

Choosing the right combination of components for your power supply PCB ensures optimal performance, reliability, and longevity. Considering factors such as electrical characteristics, form factors, and cost constraints allows engineers and designers to create power supply solutions tailored to their specific requirements.

Efficient power distribution is paramount in power supply PCB designs. Choosing the right type of power supply is crucial to meet the requirements of your application. Let's explore two commonly used power supply types: linear power supplies and switching power supplies.

Linear power supplies are characterized by their simplicity and low cost. They regulate the output voltage by dissipating excess power as heat. Linear regulators are suitable for applications with low power requirements and where heat dissipation is manageable.

The advantages of linear power supplies include low output noise and good line and load regulation. However, they suffer from lower efficiency, especially when the input-output voltage differential is significant. Due to the high power dissipation, linear power supplies typically require additional cooling mechanisms.

Switching power supplies offer higher efficiency compared to linear power supplies. They regulate the output voltage by rapidly switching power transistors on and off. This switching operation allows for higher efficiency, reduced power dissipation, and smaller form factors.

Switching power supplies are particularly well-suited for applications requiring high power and where energy efficiency is a priority. However, they can introduce more electrical noise compared to linear power supplies due to the switching operation. Careful attention must be given to filtering and noise suppression techniques to maintain optimal performance.

When selecting the power supply type for your PCB design, consider factors such as power requirements, efficiency goals, physical size constraints, and cost considerations. Understanding the advantages and limitations of each type empowers designers to choose the most suitable solution.

Mounting the power supply PCB appropriately is crucial for ensuring mechanical stability, heat dissipation, and minimizing electromagnetic interference (EMI). Let's explore some best practices that should be considered during the mounting process.

Mechanical stability is essential to prevent stress on the power supply PCB and its components. When mounting the PCB, make sure it is secure and properly supported, especially if the application involves vibrations or movement. Using suitable mounting brackets, screws, or standoffs can enhance the PCB's stability and reduce any potential for damage caused by mechanical stress.

Heat dissipation is critical in power supply PCB designs to maintain safe operating temperatures and enhance component lifespan. Consider the following techniques to improve heat dissipation:

Heat sinks: Attach heat sinks to components that generate significant heat, such as voltage regulators or power transistors. Heat sinks increase the surface area available for heat transfer, bringing down the component temperature.

Thermal vias: Using thermal vias helps conduct heat from the PCB layers to external heat sinks or larger copper areas, enhancing heat dissipation.

Proper airflow: Ensure sufficient airflow around the power supply PCB by designing appropriate ventilation or utilizing fans if necessary. Adequate airflow assists in dissipating heat and keeping the components within the acceptable temperature range.

Thermal management materials: Consider using thermal pads or thermal interface materials to improve the thermal coupling between heat-generating components and heat sinks, enabling better heat transfer.

Implementing these heat dissipation techniques in your power supply PCB design ensures optimal performance, reliability, and longevity of the electronic system.

Power supply PCBs should be designed to minimize electromagnetic interference (EMI) to prevent disturbances to other electronic components or systems. Some best practices to reduce EMI include:

Grounding and shielding: Proper grounding techniques and shielding can help attenuate electromagnetic emissions and improve the overall electromagnetic compatibility (EMC) of the power supply PCB.

Filtering: Incorporate EMI filtering components, such as ferrite beads or low-pass filters, to suppress unwanted high-frequency noise and harmonics, effectively reducing EMI.

Layout considerations: Pay close attention to the layout of traces and components on the PCB to minimize the loop area of high-current sections and reduce electromagnetic radiation.

By implementing these best practices, you can ensure mechanical stability, effective heat dissipation, and reduced electromagnetic interference in your power supply PCB design.

Ensuring the reliability of power supply PCBs is essential to avoid potential failures and ensure consistent performance. Rigorous testing and quality control measures help identify defects early in the production process and guarantee that the final product meets the desired specifications.

Comprehensive testing procedures are crucial to validate the functionality and performance of power supply PCBs before deployment. Testing may include:

Functional testing: Ensure that the power supply PCB operates as intended and delivers the correct output voltage and current under various load conditions.

Environmental testing: Subject the PCB to environmental stress tests, including temperature cycling, humidity exposure, and vibration testing, to gauge its robustness in real-world conditions.

Electrical testing: Verify parameters such as input/output voltage, current levels, efficiency, and transient response to ensure compliance with design specifications.

Safety testing: Conduct safety tests to certify that the power supply PCB meets industry standards and poses no electrical hazards to end-users.

By implementing thorough testing procedures at different stages of production, manufacturers can identify and rectify any issues early on, guaranteeing a reliable and high-performance power supply PCB.

Adhering to stringent quality control standards is paramount in the production of power supply PCBs. Quality control measures may include:

Component verification: Ensure that all components used in the PCB assembly meet the specified requirements in terms of quality, tolerance, and reliability.

IPC standards compliance: Follow industry standards set by organizations like the IPC (Association Connecting Electronics Industries) to maintain consistency and quality in PCB manufacturing.

Inspection processes: Implement thorough visual inspections, automated optical inspections (AOI), and functional testing to detect defects and ensure product quality.

Traceability: Establish traceability measures to track components, manufacturing processes, and testing results, enabling quick identification of any issues and facilitating product recalls if necessary.

By upholding strict quality control standards throughout the production cycle, manufacturers can deliver reliable, high-quality power supply PCBs that meet customer expectations and industry regulations.

Efficient heat dissipation is crucial in power supply PCB designs to prevent thermal issues, component degradation, and system failures. Let's explore some strategies to optimize heat dissipation in power supply PCBs.

Incorporating effective heat sinks is a common method to enhance heat dissipation in power supply PCBs. Heat sinks transfer heat away from high-power components such as voltage regulators or power transistors, helping to maintain optimal operating temperatures. Consider factors such as material conductivity, surface area, and mounting techniques when selecting and designing heat sinks for your PCB.

Using thermal management materials such as thermal interface pads, thermal paste, or phase change materials can improve the thermal coupling between components and heat sinks. These materials facilitate better heat transfer and improve the overall thermal performance of the power supply PCB.

By employing appropriate heat sink designs and thermal management materials, engineers can effectively manage thermal issues in power supply PCBs, ensuring operational reliability and longevity.

Power supply PCBs may encounter various issues during operation, affecting performance and reliability. Understanding common problems and their solutions is vital for maintaining the integrity of the power supply system.

Overheating is a common issue in power supply PCBs and can lead to component damage and system failures. To address overheating:

Inspect the heat dissipation mechanisms, such as heat sinks and airflow, and enhance them if necessary.

Verify that components are within their temperature limits and adjust the operating conditions if needed.

Consider redesigning the PCB layout to improve heat distribution and dissipation.

Voltage instability can result in erratic system behavior and damage electrical components. To troubleshoot voltage instability:

Check for loose connections and ensure proper grounding throughout the PCB.

Verify the integrity of voltage regulators and capacitors, replacing any faulty components.

Review the PCB layout to minimize voltage drops and interference.

Component failure can occur due to various factors such as overloading, manufacturing defects, or environmental stress. To address component failures:

Conduct thorough testing to identify defective components and replace them promptly.

Implement robust quality control measures to prevent the inclusion of faulty components in the PCB assembly.

Monitor the operational conditions of the power supply PCB regularly to detect early signs of component degradation.

By troubleshooting common power supply PCB issues proactively and implementing effective solutions, engineers can maintain the reliability and performance of electronic systems powered by these boards.

Advancements in power supply PCB design have led to the development of innovative techniques that enhance efficiency, performance, and reliability. Let's explore some advanced techniques that can be implemented to optimize power supply PCBs.

Power Factor Correction (PFC) is a technique used to improve the power efficiency of a system by correcting the phase relationship between voltage and current. PFC circuits ensure that power supply PCBs draw power in a way that minimizes losses and reduces reactive power consumption. Implementing PFC results in higher efficiency, reduced harmonic distortion, and compliance with power quality standards.

Resonant power conversion techniques, such as Zero Voltage Switching (ZVS) and Zero Current Switching (ZCS), leverage the resonance phenomenon to reduce switching losses and improve overall efficiency. By operating at resonant frequencies, these techniques minimize power dissipation, increase power density, and enhance system reliability.

Integrating advanced techniques like PFC and resonant power conversion into power supply PCB designs enables engineers to achieve higher efficiency, lower losses, and improved overall performance, making them ideal for applications demanding optimal power utilization.

The journey into the intricate world of power supply PCB boards unveils a realm where precision, efficiency, and reliability converge to power diverse electronic systems. By delving into the nuances of design, component selection, heat dissipation, and optimization techniques, engineers and enthusiasts can unlock the potential of power supply PCBs to drive innovation and technological advancement.

As technologies continue to evolve and demand for efficient power solutions rises, the future of power supply PCB boards holds immense promise. Innovations in materials, component miniaturization, and energy efficiency are reshaping the landscape of power distribution systems.

The integration of emerging technologies like GaN (Gallium Nitride) and SiC (Silicon Carbide) semiconductors, along with advanced control algorithms, is revolutionizing power supply PCB designs. These innovations are paving the way for higher power densities, reduced form factors, and increased efficiency in next-generation power supply solutions.

Additionally, the emphasis on sustainability and environmental impact is driving the development of eco-friendly power supply PCBs that prioritize energy efficiency and recyclability. As the industry moves towards greener practices, future power supply PCBs are poised to align with sustainability goals while delivering uncompromised performance.

With ongoing research, collaboration, and innovation, the future of power supply PCB boards holds endless possibilities for enhanced performance, reliability, and efficiency, shaping the next chapter in the evolution of electronic power distribution systems.

In the realm of electronic systems, power supply PCB boards stand as silent yet indispensable pillars, delivering the lifeblood of electricity to power our devices and machines. Through meticulous design, component selection, and optimization, these PCBs ensure seamless power distribution, reliability, and efficiency across a myriad of applications.

By embracing the principles of effective heat dissipation, quality control, and advanced design techniques, engineers and designers can navigate the complexities of power supply PCB boards with confidence and precision. As technology continues to advance and challenges evolve, the foundational principles of integrity, innovation, and performance remain at the core of each power supply PCB design.

As we bid farewell to the realms of power supply PCBs, let us carry forward the lessons learned and the insights gained, forging ahead into a future where power efficiency, reliability, and sustainability intertwine to illuminate the path towards technological excellence.

A power supply PCB is an electronic circuit board responsible for regulating and delivering electrical power to various components of an electronic system. It ensures stable voltage and current output for smooth and reliable operation.

Linear power supplies are generally less efficient than switching power supplies, especially in applications where there is a significant difference between input and output voltage levels. Switching power supplies offer higher efficiency but may introduce more electrical noise.

Overheating in power supply PCBs can be caused by inadequate heat dissipation, high ambient temperatures, excessive current loads, or improper component selection. Effective heat sink designs and thermal management techniques can help mitigate overheating issues.

In some cases, components on a power supply PCB can be replaced or repaired if they are damaged or faulty. However, extensive damage or issues with the PCB traces may require professional repair or replacement of the entire board.

While power factor correction (PFC) enhances power efficiency and reduces harmonic distortion, its necessity depends on the specific application requirements and regulatory standards. In applications where high efficiency is critical, implementing PFC can be beneficial.

With the insights provided in this article, readers are equipped to navigate the realm of power supply PCB boards with confidence, unleashing the potential of efficient and reliable power distribution systems in the ever-evolving landscape of technology.

By delving into the intricacies of power supply PCB boards, this article aims to empower readers with knowledge and insights to navigate the complexities of power distribution with confidence and expertise. From design considerations to optimization techniques, the world of power supply PCBs unveils a realm where precision, efficiency, and reliability converge to power the innovations of tomorrow.