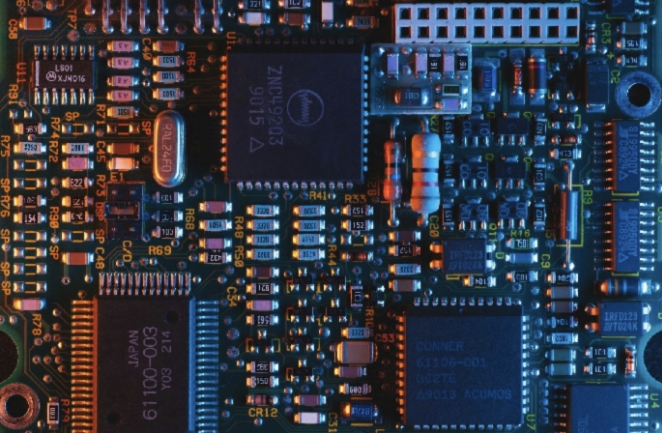

Electronic devices have become an integral part of our everyday lives, from smartphones to home appliances. Behind the functionality of these devices lies a complex network of electrical connections embedded within Printed Circuit Boards (PCBs). To ensure the reliability and optimum performance of these PCBs, an inspection process known as Automatic Optical Inspection (AOI) is employed in the production line. In this article, we will dive into the realm of AOI, exploring its significance, capabilities, and application in the manufacturing process.

In the world of electronics manufacturing, quality is paramount. The inspection process plays a crucial role in maintaining the standards set for the end products. AOI is a technique that allows for the automated inspection of PCBs, employing high-resolution cameras and sophisticated algorithms to analyze and detect potential defects or faults. By utilizing advanced image processing software and algorithm-based programming, AOI systems provide reliable and efficient visual inspections.

The inspection process entails several steps to ensure a thorough examination. First, the PCB is fed into the AOI machine, which captures high-resolution images of the board from different angles. Then, the automated system analyzes these images, comparing them with pre-programmed standards and known good boards. The processed data is then used to identify any discrepancies or anomalies in the PCB assembly, such as misaligned components or soldering issues.

AOI holds a vital position within the production line. By detecting defects early in the manufacturing process, it significantly reduces the chances of faulty devices reaching the market. This not only saves costs associated with product recalls but also safeguards the reputation of the manufacturer. AOI acts as a reliable gatekeeper, ensuring that high-quality standards are maintained throughout the assembly and manufacturing stages.

Before delving deeper into AOI, it is essential to comprehend the significance of PCBs. These boards provide the structural and electrical groundwork for electronic devices. Composed of layers of copper traces and insulated materials, PCBs facilitate the interconnection of various components. Understanding PCBs is crucial since AOI directly relates to their functionality and integrity.

At the heart of AOI lies the dedicated AOI machine. This machine combines advanced hardware, such as high-resolution cameras and precision lighting setups, with intelligent software programming. These elements work in tandem to capture detailed images of the PCB and perform accurate inspections. The AOI machine operates seamlessly within the production line, integrating with other systems to ensure efficient PCB assembly.

One of the primary tasks of AOI systems is to identify short circuits and open circuits on PCBs. Short circuits occur when two or more electrical nodes are unintentionally connected, causing an abnormal flow of current. Open circuits, on the other hand, result from a break in the electrical path due to disconnected components or faulty connections. AOI machines utilize their capabilities to precisely detect these common faults, offering faster and more accurate inspections.

Another critical aspect of AOI is analyzing the accuracy of component placement during PCB assembly. The correct alignment of components and solder joints is crucial for electrical connectivity and overall product functionality. AOI systems, armed with high-resolution cameras, capture detailed images that highlight potential issues like skewed or misaligned parts. By flagging such discrepancies, the AOI machine ensures that components are correctly placed, minimizing the chances of malfunctions.

The heart and soul of AOI lie in its algorithm-based programming. Utilizing various algorithms, AOI systems process the captured images and interpret the data to identify defects accurately. These algorithms are designed to recognize specific patterns, shapes, and features associated with both good and faulty PCBs. By efficiently analyzing the captured images, AOI systems can swiftly identify potential defects that might not be easy to detect visually.

To achieve accurate results, proper lighting is essential in AOI systems. Different lighting techniques and setups are used to effectively capture PCB images. Carefully configuring the light sources ensures that potential defects are illuminated for inspection. By optimizing the lighting conditions, AOI systems enhance their ability to detect faults, enabling a comprehensive examination of the PCB.

In addition to component placement and soldering issues, AOI is proficient in detecting surface feature defects on PCBs. These defects can include scratches, stains, or cracks on the surface of the board. AOI systems are equipped with advanced image processing software that analyzes the surface features, comparing them with predefined standards. By identifying such defects, AOI serves as a powerful tool in maintaining the visual integrity and quality of PCBs.

The integration of AOI within the manufacturing process significantly contributes to the overall quality of the end products. By automating inspections, AOI minimizes the risk of human error, increases the inspection speed, and ensures consistent quality throughout the production line. AOI acts as a safeguard, guaranteeing that only PCBs meeting the defined standards proceed further into the manufacturing process.

Modern PCBs can consist of thousands of soldered joints, making manual inspection a time-consuming and error-prone task. AOI systems, on the other hand, excel in inspecting large quantities of soldered joints with speed and accuracy. By precisely examining each joint, AOI eliminates the limitations of human inspection, ensuring that even intricate soldering connections meet the required standards.

Although AOI brings numerous benefits to PCB manufacturing, some challenges and limitations persist. PCB designs with complex layouts or densely populated components might pose challenges for AOI systems, as the intricate placements can hinder proper imaging and analysis. Additionally, AOI might encounter limitations in detecting faults such as intermittent issues or defects hidden beneath components. However, continuous advancements in AOI technology are addressing these challenges, evolving the capabilities of AOI systems.

As technology progresses, so does AOI. The future of AOI in PCB manufacturing holds exciting prospects. Advancements in AI and machine learning are enhancing the capabilities of AOI systems, enabling them to handle even more complex inspections with higher precision. Additionally, the integration of AOI with other aspects of the production line, such as automated component placement, is further streamlining the manufacturing process. The continuous development and refinement of AOI technology promise a future where inspection processes become even more efficient and effective.

Automatic Optical Inspection (AOI) plays a fundamental role in ensuring the quality of PCBs within the manufacturing process. By combining high-resolution imaging, advanced algorithms, and accurate visual inspections, AOI systems identify potential defects in PCB assembly and facilitate early detection, guaranteeing the creation of reliable and high-quality electronic devices. As AOI technology continues to evolve, its contributions to the manufacturing industry are becoming increasingly indispensable.

Q1: How does AOI compare to manual inspection methods?

AOI considerably outperforms manual inspection methods in terms of speed, accuracy, and consistency. It eliminates the limitations of human inspection, reducing the chances of overlooking defects or inconsistent assessments.

Q2: Can AOI systems handle various types of PCBs and circuitry configurations?

Yes, AOI systems are designed to handle different types of PCBs and adapt to varying circuitry configurations. They can accommodate PCBs with diverse layouts and accommodate different sizes and shapes.

Q3: Is AOI only applicable for large-scale PCB manufacturing?

No, AOI is valuable for PCB manufacturing at various scales. Whether it's high-volume production or small-batch prototyping, AOI helps maintain quality and ensure the integrity of the PCB assemblies.

Q4: Can AOI systems detect defects in hidden areas of PCBs?

AOI systems primarily focus on visible areas of the PCB. Detecting defects in hidden regions beneath components might pose challenges. However, advancements in technology are addressing this limitation, and AOI systems are becoming more adept at analyzing obscured areas.

Q5: How does AOI impact the overall cost of production?

While the initial investment in AOI systems might increase the production cost, it significantly reduces costs associated with manual inspections, rework or recalls due to faulty products. In the long run, AOI contributes to cost savings and improved efficiency.