As electronic products continue to become smaller and more powerful, advanced chip packaging technologies play a crucial role. Among these technologies, one widely used approach is Flip Chip BGA (Ball Grid Array) assembly, which facilitates highly integrated circuit board designs and ensures reliable electrical connections.

Flip Chip BGA assembly is an advanced soldering technique that offers numerous benefits in semiconductor device packaging. In this article, we will explore the working principle, components, and advantages of this innovative assembly method.

Understanding Flip Chip Assembly:

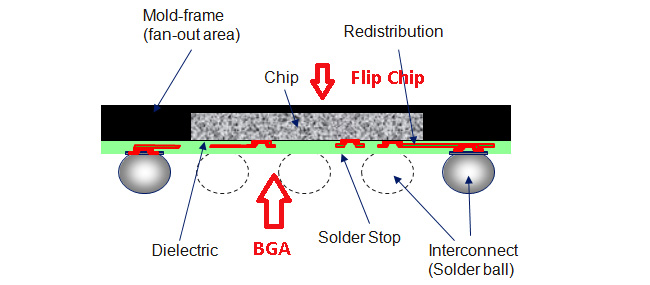

Flip Chip assembly involves directly connecting the active side of a semiconductor chip to a circuit board. Unlike traditional wire bonding, where the connections are made using fine wires, Flip Chip assembly utilizes solder bumps or balls for electrically joining the chip and the circuit board.

Components Involved:

The main components involved in Flip Chip BGA assembly are the chip, the circuit board, and the Flip Chip package. The chip, typically made of silicon, contains the integrated circuits and other components necessary for electronic functionality. The circuit board, often made of fiberglass or other composite materials, serves as a platform to mount and interconnect various components. The Flip Chip package acts as a mediator, providing the necessary connections between the chip and the circuit board.

The Role of Solder Reflow:

Solder reflow is a crucial step in Flip Chip BGA assembly. During this process, the solder bumps on the chip and the corresponding solder pads on the circuit board are heated using hot air or infrared radiation. The heat melts the solder, causing it to bond with the metallic layers present on both the chip and the circuit board. Once cooled, the solder solidifies, forming a reliable and electrically conductive connection.

Advantages of Flip Chip BGA Assembly:

4.1 Enhanced Electrical Performance:

The direct electrical connections achieved through Flip Chip BGA assembly offer several advantages compared to wire bonding. By eliminating the wire lengths, inductance and parasitic capacitance are significantly reduced, resulting in improved signal integrity and higher operating frequencies.

4.2 Increased Package Density:

Flip Chip BGA allows for densely packed layouts due to the smaller size of soldered bumps compared to wire bonds. This enables the integration of a higher number of components within a limited circuit board area, leading to smaller and more compact electronic devices.

4.3 Improved Thermal Management:

Flip Chip BGA assembly offers superior thermal management capabilities. With direct chip-to-board connections, heat generated by the semiconductor devices can be dissipated more efficiently through the circuit board and into the surrounding environment. This is particularly beneficial in high-power applications where thermal conductivity is crucial.

4.4 Reduced Interconnect Length:

Since Flip Chip BGA assembly eliminates the need for wire bonds, the interconnect length between the chip and the circuit board is minimized. This results in reduced signal propagation delays and improved overall system performance.

Applications of Flip Chip BGA Assembly:

Flip Chip BGA assembly finds applications in a wide range of industries, including consumer electronics, telecommunications, automotive, aerospace, and medical devices. Its benefits in terms of miniaturization, enhanced electrical performance, and improved thermal dissipation make it an ideal choice for high-performance and space-constrained applications.

Flip Chip BGA assembly has revolutionized semiconductor device packaging with its ability to achieve highly integrated circuit board designs and reliable electrical connections. The direct chip-to-board connections, reduced interconnect lengths, and improved thermal management contribute to enhanced electrical performance and compact electronic devices. As technology continues to advance, Flip Chip BGA assembly will continue to play a crucial role in meeting the demands of smaller, faster, and more powerful electronic products.