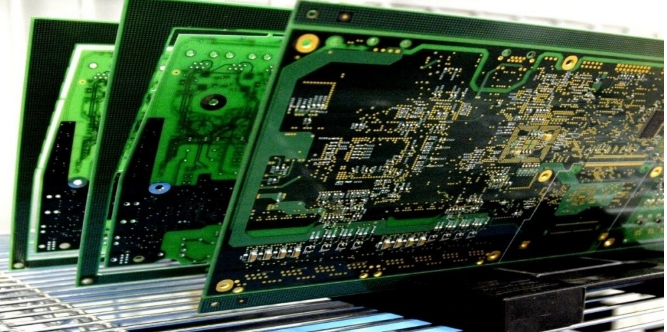

In the world of electronics, the demand for customized solutions has grown exponentially. Creating a custom circuit board allows you to tailor its design to suit your specific needs. Whether you're a hobbyist or an industry professional, custom circuit boards offer greater flexibility, functionality, and control. In this article, we will delve into the process of making a custom circuit board, exploring electronic components, PCB design software, Gerber files, PCB layout, surface mount technology, PCB manufacturers, and more.

Before diving into the intricacies of custom circuit boards, it's essential to understand the role of electronic components. Electronic components are the fundamental building blocks of any circuit. They include resistors, capacitors, transistors, diodes, integrated circuits, and more. Each component plays a crucial role in determining the behavior and functionality of the circuit.

To design a custom circuit board, you will need specialized software known as PCB design software. These tools provide a platform for creating and editing circuit schematics, designing the PCB layout, and ensuring electrical connectivity. Popular PCB design software options include Altium Designer, EagleCAD, and KiCad. These user-friendly programs offer various features to simplify the design process and enhance productivity.

Once you've designed your custom circuit board using PCB design software, you need to generate Gerber files. Gerber files are the industry standard for representing PCB designs to manufacturers. They provide all the necessary information regarding the placement of components, traces, pads, and drill holes. These files are essential for the manufacturing process, allowing PCB manufacturers to accurately produce your design.

The PCB layout is a crucial step in creating a custom circuit board. It involves determining the physical arrangement of components and their interconnections on the circuit board. A well-thought-out PCB layout ensures optimal signal flow, reduces interference, and minimizes the risk of electrical shorts. It is essential to consider factors such as component placement, trace routing, and ground planes during the layout process.

When designing a custom circuit board, several considerations should be taken into account. Firstly, it's essential to define the purpose and requirements of the circuit board. Will it be used in a high-speed application or a low-power device? Secondly, selecting the appropriate materials for your board is crucial. Factors such as substrate type, copper weight, and solder mask play a significant role in the board's performance and durability. Lastly, thermal management and electromagnetic compatibility (EMC) considerations should not be overlooked.

Surface mount technology (SMT) has revolutionized the electronics industry by offering smaller, lighter, and more efficient components. SMT components do not have leads, making them ideal for densely packed circuit boards. When integrating SMT components into your custom circuit board design, ensure proper component footprint creation and precise soldering techniques. SMT components should be aligned correctly and soldered using reflow or wave soldering techniques.

Selecting a reliable PCB manufacturer is crucial for the success of your custom circuit board project. Consider factors such as their expertise, track record, manufacturing capabilities, and adherence to industry standards. Verify their ability to handle your design specifications and desired quantities. It is advisable to request samples, review customer feedback, and assess their technical support before making a final decision.

Once you have chosen a PCB manufacturer, the next step is to submit your Gerber files. Ensure that your Gerber files meet the manufacturer's specific requirements, including their preferred file formats and layer configuration. Double-check for any design errors or omissions to avoid delays or discrepancies during the manufacturing process. Communicate with the manufacturer to clarify any uncertainties and provide them with all necessary documentation.

After the manufacturing process is complete, you will receive the fabricated circuit board from the manufacturer. The next step is to assemble the components onto the board. This process involves carefully placing the electronic components onto their designated locations and soldering them to the board. It is crucial to use appropriate soldering techniques and tools to ensure reliable connections and avoid damage to the components or the PCB.

Once the components are assembled, the next step is to electrically connect them to complete the circuit. This involves creating electrical pathways, known as traces, to link the various components on the board. Carefully consider trace routing, ensuring proper spacing, impedance control, and signal integrity. Observe best practices for grounding and power distribution, as well as thermal management to safeguard against potential issues.

Before deploying your custom circuit board, thorough testing is vital to ensure its functionality and reliability. Test the board for electrical continuity, ensuring that all connections are intact and performing as intended. Perform functional tests to verify the behavior of the circuit under different scenarios and loads. Utilize appropriate test equipment, such as multimeters, oscilloscopes, and logic analyzers, to validate the performance of your custom circuit board.

Creating a custom circuit board opens up a world of possibilities for innovators and technology enthusiasts. By understanding electronic components, utilizing PCB design software, generating Gerber files, considering PCB layout and surface mount technology, selecting the right PCB manufacturer, and following proper assembly and testing processes, you can bring your unique circuit board design to life. Embrace the opportunities that custom circuit boards offer and embark on a journey of creativity, functionality, and success.

What are the advantages of using a custom circuit board?

Custom circuit boards allow for tailored designs to suit specific needs.

They offer greater flexibility, functionality, and control than standard circuit boards.

Which PCB design software is the best for beginners?

KiCad and EagleCAD are popular choices for beginners due to their user-friendly interfaces and extensive online documentation.

Can I create a custom circuit board without any programming knowledge?

Yes, programming knowledge is not a prerequisite for creating a custom circuit board. However, understanding basic electronics principles is beneficial.

What is the typical turnaround time for PCB manufacturing?

Turnaround time can vary depending on factors such as manufacturer location, complexity of the design, and quantity required. It typically ranges from a few days to a few weeks.

How can I ensure the reliability of my custom circuit board?

Ensuring proper design practices, adequate testing, and selecting high-quality components and materials are keys to maximizing the reliability of your custom circuit board.