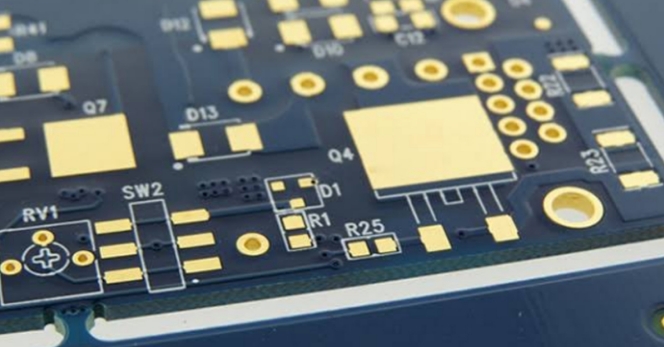

When it comes to ensuring the optimal functionality and longevity of printed circuit boards (PCBs), choosing the right surface finish is crucial. One popular technique preferred by industry professionals is gold plating. In this article, we will explore the significance of gold plating in the PCB manufacturing process along with its benefits, types of gold, the plating process itself, and much more. So, let's dive in!

Electroless Nickel Immersion Gold (ENIG) is a widely used surface finish method in the PCB industry. It involves depositing a very thin layer of nickel onto the copper surface, followed by a layer of gold. ENIG provides excellent protection against oxidation and offers good conductivity, making it suitable for a variety of applications.

Immersion gold plating is a method where a thin layer of gold is directly deposited onto the copper surface. It ensures the surface of the PCB has better solderability and prevents oxidation. Immersion gold, similar to ENIG, provides outstanding conductivity and corrosion resistance.

Another technique employed for PCB surface finishing is electroplated gold. This process involves the electrolytic deposition of gold onto the copper surface. Electroplated gold offers exceptional conductivity and a smooth surface finish, making it well-suited for various high-performance applications.

One of the significant advantages of gold plating PCBs is the enhanced wear resistance it provides. The thin layer of gold acts as a protective barrier, safeguarding the PCB from mechanical stress and environmental factors, ultimately extending its lifespan.

Gold is known for its outstanding oxidation resistance properties. By employing gold plating, PCBs become highly resistant to tarnishing and corrosion, ensuring reliable performance over an extended period. This resistance is particularly crucial in environments with high humidity or harsh conditions.

Thanks to its superior electrical conductivity, gold plating on PCBs significantly improves electricity conduction. Gold is an excellent conductor of electricity and offers low contact resistance, preventing signal loss and minimizing interference. This makes it ideal for applications that require high-speed and high-frequency signal transmission.

One commonly used method is depositing a thin layer of gold directly onto the copper surface. This type of plating is primarily focused on providing better solderability. It ensures the copper pads have a smooth and uniform gold layer, facilitating successful solder joints during the assembly process.

Gold fingers refer to the gold-plated contact pads found along the edge of PCBs. These gold-plated connectors improve reliability and conductivity. They enable the PCB to establish a secure connection with other devices or components, making them highly desirable in applications such as memory cards, graphic cards, and more.

Often, to improve adhesion and durability, a layer of nickel is initially plated onto the copper surface before depositing gold. Nickel provides excellent corrosion resistance and acts as a barrier between the copper and gold layers.

The suitability of gold-plated PCBs depends on specific application requirements. Factors to consider include environmental conditions, cost, electrical conductivity, and aesthetic appeal. Gold plating is favored in high-reliability applications, defense systems, aerospace equipment, and any project where durability and performance are paramount.

Gold plating on PCBs undergoes a step-by-step process to ensure optimal adhesion and distribution of the gold layer. Let's explore the various stages involved.

Before the plating process begins, the PCB undergoes thorough inspection and cleaning. Any dirt, dust, or contaminants on the surface need to be removed to ensure effective plating.

In the pre-cleaning stage, the PCB goes through a series of cleaning procedures. This removes any remaining impurities and prepares the surface for the next steps. Typical cleaning methods include ultrasonic cleaning, chemical cleaning, or plasma cleaning.

To promote adhesion between the copper surface and the gold layer, an activation step is crucial. This process involves applying a catalyst or activator to the cleaned surface. The catalyst ensures a strong bond between the copper and the gold later in the process.

The immersion gold plating itself is the core step in the process. The PCB is submerged into an electrolyte solution containing gold ions. Through a controlled electrochemical reaction, gold from the solution is deposited onto the copper surface, forming a uniform and thin layer of gold.

Following the gold plating, the PCB goes through rinsing stages to remove any excess solutions and particles from the surface. Proper rinsing is essential to prevent contamination and ensure the longevity of the gold plating. Once rinsed, the PCB is dried thoroughly.

In the final stage, the gold-plated PCB undergoes thorough inspection and testing. This verifies that the gold plating is evenly distributed, of high quality, and adheres properly to the copper surface. The PCB is examined for any defects, such as voids, pinholes, or quality issues, to ensure it meets the required specifications.

While gold plating has numerous advantages, it's important to compare it with other surface finishes available for PCBs. Let's briefly explore a few common options.

HASL is a cost-effective surface finish technique involving the application of hot solder to create a solderable surface. However, HASL may not be suitable for fine-pitch components due to uneven coating and potential reliability issues in certain environments.

OSP is an environmentally friendly and cost-effective surface finish technique that creates a thin protective layer on the copper surface. Although OSP is widely used, it offers limited shelf life and requires careful handling to avoid oxidation.

Similar to immersion gold, immersion silver is a surface finish that provides excellent conductivity. However, it is more prone to tarnishing and not recommended in environments with sulfur-containing compounds or high humidity.

Electrolysis nickel and gold plating combines the benefits of both nickel and gold plating. With good corrosion resistance and superior conductivity, it is widely used in high-reliability applications. However, the process is more complex and expensive than traditional gold plating.

Gold plating presents specific challenges that need to be addressed to ensure successful results. Some common challenges include controlling gold thickness, achieving uniform plating, and maintaining an optimal balance of chemicals during the plating process. These challenges are often overcome through advanced equipment, stringent process control, and well-established quality management systems.

Can gold plating prevent oxidation on PCBs?

Gold plating is highly effective in preventing oxidation on PCBs. The thin layer of gold acts as a protective barrier, preventing the copper surface from coming into contact with oxygen and moisture that can lead to oxidation.

How thick is the gold layer in gold-plated PCBs?

The thickness of the gold layer in gold-plated PCBs is typically measured in microinches or microns, with common values ranging from 1 to 3 μin or 0.025 to 0.075 μm.

What is the difference between immersion gold and ENIG?

While both immersion gold and ENIG involve depositing a thin layer of gold onto a copper surface, ENIG also includes an intermediate layer of electroless nickel beneath the gold. The additional nickel layer in ENIG enhances durability and solderability compared to immersion gold alone.

Are there any drawbacks to gold plating PCBs?

One drawback of gold plating PCBs is the relatively higher cost compared to other surface finishes. Additionally, the gold plating process can be more complex, requiring careful control of various parameters to achieve consistent results.

Can gold plating improve the durability of printed circuit boards?

Yes, gold plating significantly improves the durability of printed circuit boards. The gold layer acts as a protective coating, preventing oxidation, wear, and corrosion, thereby extending the PCB's lifespan.

In conclusion, gold plating offers invaluable benefits to the world of PCB manufacturing. From enhanced wear resistance to improved electricity conduction and oxidation resistance, gold plating ensures superior performance and durability. By understanding the gold plating process, the types of gold used, and the challenges involved, you can make informed decisions when it comes to choosing the ideal surface finish for your PCBs.

Remember, the choice of a gold-plated PCB is an investment in reliability and longevity, making it a preferred option for high-reliability applications, aerospace, defense, and other demanding environments. So, whether you're designing your next cutting-edge device or working on a critical project, consider the power of gold plating PCBs in ensuring optimal performance and longevity.