In electronic manufacturing, inspecting products is important for high quality and reliability in a fast-paced industry. The Automated Optical Inspection (AOI) for PCBs is an important part of the inspection process. This technology helps detect defects and make sure printed circuit boards (PCBs) are in good condition.

During PCB assembly, issues may arise like excessive or insufficient solder, short circuits, open circuits, and component mistakes. In the past, people used to rely on visual inspection, but it wasn't always accurate or fast. This is where AOI machines and systems come into play.

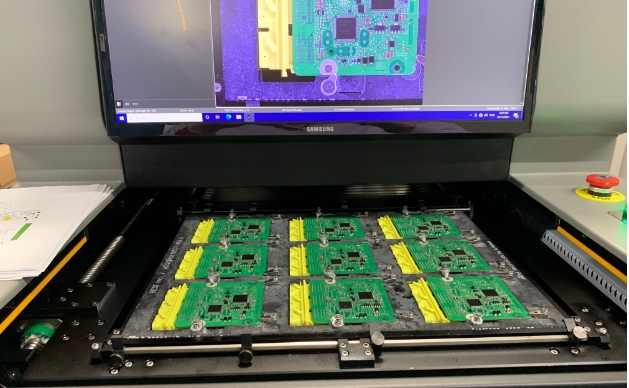

An AOI machine uses advanced technology to check PCBs with high-resolution cameras and image processing software. The AOI system uses various algorithms to detect defects and issues on a PCB. This helps to improve the efficiency and accuracy of the inspection process.

One of the primary functions of an AOI machine is the detection of excessive or insufficient solder. Solder joints are critical connections that ensure proper electrical connections between components on the PCB. Excessive solder can lead to short circuits, while insufficient solder may result in weak or unreliable connections. The AOI system analyzes the solder joints and identifies any irregularities using its machine vision capabilities, enabling it to make necessary corrections.

Component placement accuracy is another crucial aspect of PCB assembly. Incorrectly placed components can cause malfunctions or even render the entire PCB useless. An AOI machine helps compare component placement to specifications, making sure all components are in the right place.

The AOI system operates by capturing high-resolution images of the PCB under inspection. Special software checks the pictures. The software looks for things like correct part placement, quality soldering, and any errors or issues. The system checks pictures against rules to quickly solve problems, making it easier to find and fix issues.

Machine vision is important in AOI, allowing the system to inspect PCBs and assess their quality by "seeing" them. The cameras within the AOI machine can capture images from multiple angles, providing a comprehensive view of the PCB. Moreover, the AOI system can accurately detect defects that may not be visible to the human eye. This technology significantly enhances the inspection process and minimizes the risk of faulty products reaching the market.

To ensure reliable and accurate inspection, an AOI machine requires suitable lighting conditions. A properly calibrated light source is essential for achieving optimal image quality. The AOI system uses different types of lighting, like backlighting and oblique lighting, to light up the PCB from different angles. This helps to see defects better and improve detection accuracy.

The implementation of an AOI system in the manufacturing process offers numerous benefits. It improves inspection speed, eliminates human error, and enhances overall quality control. By utilizing sophisticated machine vision capabilities, the AOI machine provides reliable and consistent results, minimizing the chances of defects slipping through the production line.

In conclusion, automated optical inspection (AOI) for PCBs is a critical technology in the electronic manufacturing industry. It ensures quality control and defects detection throughout the manufacturing process. The AOI system uses technology to identify and correct issues in manufacturing. It can detect problems such as excessive or insufficient solder, incorrect component placement, short circuits, open circuits, and other issues. This system utilizes machine vision and image processing software to analyze the products. It helps ensure that the final products meet quality standards. By utilizing AOI machines, manufacturers can enhance their inspection processes, improve efficiency, and ultimately deliver products of the highest quality.