As technology advances, the need for advanced electronic devices continues to escalate. Efficient and dependable circuit boards are essential for LED lighting, power electronics, and other high-power applications.

This article explains aluminium PCB circuit boards, discussing their structure, benefits, and uses in heat transfer and cooling systems.

An aluminium PCB is important in electronic devices, like a regular PCB. However, it diverges in structure and material composition. Manufacturers use aluminium to make aluminum PCBs, also known as aluminium substrates, with a layer of copper foil. This configuration facilitates superior heat dissipation and high thermal conductivity.

Effective thermal management is pivotal in electronic devices to avert the adverse impacts of heat on performance and longevity. Efficient heat dissipation is particularly vital in LED lighting and power electronics applications. With their high thermal conductivity, aluminium PCBs tackle this challenge and offer a compelling solution for enhanced thermal management.

Aluminium-based PCBs proffer several advantages over traditional counterparts. Let's explore some:

Enhanced Heat Dissipation

Ensuring optimal heat dissipation is paramount for electronic devices operating at elevated temperatures. Aluminium PCBs excel in this realm because of their stellar thermal conduction properties. The aluminium base material efficaciously diverts heat away from delicate components, averting overheating and ensuring peak performance.

High Thermal Conductivity

The thermal conductivity of a material dictates its heat transfer capacity. Aluminium, being a metal renowned for outstanding thermal conductivity, enables efficient heat transfer within the circuit board. Applications necessitating rapid and effective dissipation of generated heat particularly rely on this trait.

Eco-Friendly Nature

In recent years, environmental sustainability has gained traction. Aluminium PCBs are more environmentally friendly than regular PCBs because they use safe and recyclable materials.

Aluminium PCBs outshine copper foil layer PCBs commonly found in traditional circuit boards. Let's delve into the comparison to discern the superiority of aluminium PCBs.

Efficiency in Heat Dissipation

While copper boasts moderate thermal conductivity, aluminium surpasses it, rendering aluminium PCBs more adept for high-power applications. These PCBs help electronic components maintain cool temperatures, preventing damage from overheating.

Thermal Resistance

In addition to enhancing heat dissipation, aluminium PCBs flaunt lower thermal resistance in comparison to copper foil layer PCBs. Diminished thermal resistance facilitates smoother heat conduction through the circuit board, amplifying heat transfer efficiency.

Comprehending heat transfer in aluminium PCBs is paramount for effective thermal management.

Heat Conduction by Aluminium

Aluminium's superb thermal conductivity guarantees efficient heat conduction throughout the PCB. It promptly absorbs heat from electronic components and redistributes it across the aluminium base material.

Role of the Base Material

The aluminium base material functions as a heat spreader, evenly dispersing heat across the circuit board. By curbing temperature fluctuations, it mitigates hotspots that could impede component performance or induce premature failure.

Efficient thermal management is particularly critical in LED lighting applications because of the substantial heat generated by LED diodes. Aluminium PCBs confer several benefits in this domain.

Significance of Aluminium PCBs in LED Lights

LED lights have revolutionized the lighting industry with energy-efficient and long-lasting illumination. However, LED diodes emit substantial heat during operation. Aluminium PCBs efficiently dissipate this heat, ensuring optimal functioning and prolonging the lifespan of LED lights.

Advantages in LED Thermal Management

Aluminium PCBs employed in LED lights bolster heat dissipation, mitigating the risk of thermal stress on LED diodes. These PCBs maintain consistent light output and enhance performance by proficiently channelling heat away from crucial electronic components, even in challenging operating conditions.

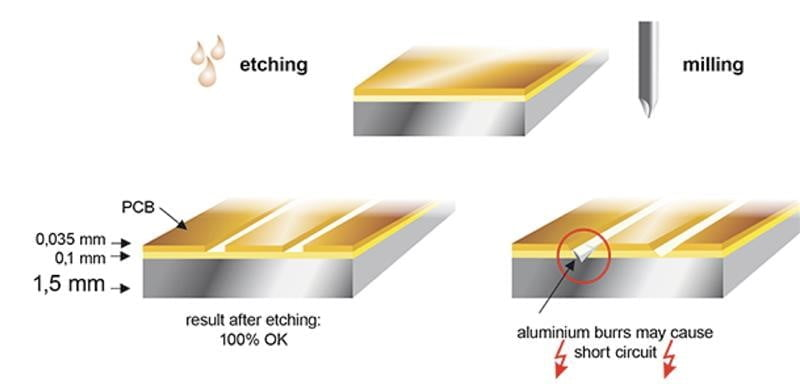

Producing aluminium PCBs demands expertise and precision. Seasoned aluminium PCB manufacturers adhere to a series of steps to yield top-tier results.

Aluminium PCB Manufacturers

Selecting a reputable aluminium PCB manufacturer is imperative to ensure the production of high-caliber PCBs. Established manufacturers with cutting-edge facilities can guarantee the dependability and performance of the end product.

Steps in Aluminium PCB Production

The manufacturing process encompasses various stages, including design, material selection, and fabrication. Meticulous design specifications dictate the selection of aluminium substrates, copper foils, and dielectric insulator layers to achieve the desired thermal conductive properties and performance.

The quality of materials utilized in aluminium PCBs significantly influences their performance and longevity. Several key components contribute to the overall efficacy of aluminium-based circuit boards:

Aluminium Substrates

Aluminium substrates constitute the core of aluminium PCBs, playing a pivotal role in heat dissipation. Employing high-quality aluminium ensures optimal thermal conductivity and guarantees reliable performance under high-temperature conditions.

Copper Foils

Copper foils are indispensable components in aluminium PCBs, providing electrical connectivity. The copper layer melds with the aluminium substrate to ensure efficient heat transfer and electrical connection between components.

Dielectric Insulator Layers

Dielectric insulator layers separate the copper and aluminium layers of the PCB, forestalling electrical short circuits and ensuring proper functionality. We meticulously choose these insulating layers to provide mechanical strength and electrical insulation properties.

Endowed with distinctive properties and construction, aluminium PCBs offer several unmistakable benefits for electronic devices across diverse industries. Let's delve deeper into these advantages:

Aluminium PCBs excel in heat dissipation owing to their exceptional thermal conductivity and efficient heat transfer capabilities. These circuit boards keep essential components cool, ensuring stable operations and forestalling damage from overheating.

By mitigating the perils associated with overheating, aluminium PCBs significantly contribute to the longevity of electronic components. Electronics outfitted with aluminium-based PCBs encounter minimized thermal stress, leading to heightened reliability and an extended lifespan.

Leveraging aluminium-based PCBs enables the development of lighter and more compact electronic devices. Aluminium circuit boards outshine traditional PCBs in weight, size, and thermal performance.

Aluminium PCBs may cost more at first, but they save money in the long run by managing heat better. The augmented efficiency and dependability of electronic devices precipitate reduced maintenance and replacement expenses.

Endowed with exceptional qualities, aluminium PCBs find resonance across manifold industries necessitating adept heat management.

LED Streetlights

The use of aluminium PCBs is prevalent in LED streetlights attributed to the arduous operational conditions these luminaires encounter. Bolstered by superior thermal conductivity, aluminium-based circuit boards ensure functionality, longevity, and consistent light emission.

Automotive LED Lights

With burgeoning energy efficiency, LED lights progressively supplant traditional automotive lighting. Aluminium PCBs are indispensable in LED lighting applications, ensuring diode maintenance at feasible temperatures and optimal functionality under challenging circumstances.

Indoor LED Light Fixtures

Indoor lighting solutions mandate efficient thermal management for optimal performance and durability. Aluminium-based PCBs, equipped with requisite heat dissipation capabilities, contribute to the reliability and robustness of indoor LED lighting systems.

Power electronics pivot on crucial circuitry necessitating effective thermal regulation. Aluminium PCBs find utility across an array of power electronic devices.

Power Supplies

Power supply units often emanate substantial heat during operation. Aluminium-based PCBs aid in efficacious heat dissipation, ensuring consistent performance and prolonging the lifespan of power supplies.

Motor Controllers

Enabling efficient heat dissipation is pivotal in motor controllers. By harnessing aluminium PCBs, motor controllers can navigate high-temperature terrains sans compromise on performance, reliability, or functionality.

1. Can aluminium PCBs withstand high temperatures?

Affirmative! Engineers design aluminium PCBs to withstand high temperatures commonly found in electronic devices. Their superior heat dissipation properties, coupled with aluminium's thermal conductivity, assure reliable performance even in taxing operational conditions.

2. Are aluminium PCBs costlier than traditional PCBs?

While aluminum PCBs may cost more upfront, they save money in the long run compared to traditional PCBs. Heightened thermal management and the prolonged lifespan of electronic components translate into diminished maintenance and replacement overheads over time.

3. Can we use aluminium PCBs for high-power applications?

Indubitably, aluminium PCBs are apt for high-power applications owing to their superior heat dissipation capabilities. Efficacious heat management ensures operational stability and optimal performance under demanding scenarios.

4. Is repairing or modifying aluminium PCBs plausible?

Rectifying or altering aluminium PCBs necessitates specialized expertise and knowledge. Seek professional aid from seasoned technicians to safeguard the integrity and reliability of the circuit board.

5. Do aluminium PCBs harbour any disadvantages?

While aluminium PCBs tout myriad advantages, it is imperative to consider their specific requisites. Aluminium circuit boards may not be optimal for scenarios mandating high-frequency signals or wherein electrical insulation assumes primacy. Think about what your project needs and ask an expert for advice on the best type of PCB to use.

In summary, aluminium PCB circuit boards, boasting high thermal conductivity, superior heat dissipation, and ecological friendliness, assume a pivotal role in contemporary electronics. By skillfully managing heat and augmenting thermal conductivity, these circuit boards secure the dependability, longevity, and optimal performance of electronic devices across diverse industries. Aluminium PCBs are a good option for LED lighting and power electronics. They are versatile and efficient, meeting the growing technological demands.