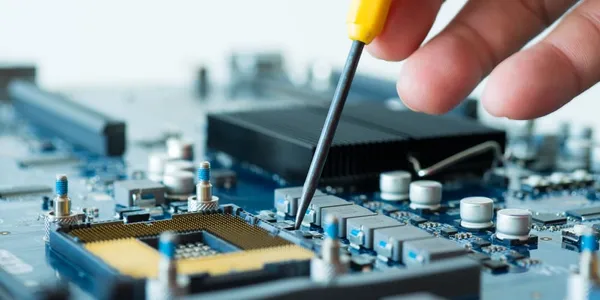

In today's tech-driven world, Printed Circuit Boards (PCBs) are the backbone of electronic devices, playing a pivotal role in ensuring seamless connectivity and functionality. As the demand for electronics continues to rise, the need for affordable and efficient PCB fabrication has become more crucial than ever. This article delves into the realm of inexpensive PCB fabrication, exploring key strategies, technologies, and considerations to achieve high-quality PCBs at competitive prices.

Printed circuit board fabrication is a multi-faceted process encompassing design, prototyping, manufacturing, and assembly. PCB prototypes serve as crucial initial models for testing designs and functionalities before mass production. Efficient PCB design ensures optimal utilization of resources, leading to cost-effective production. Embracing state-of-the-art technologies and methodologies optimizes the fabrication process, enhancing precision and reliability.

Gerber files are the lifeline of PCB fabrication, containing essential design information such as copper layers, solder masks, and silkscreens. PCB manufacturers rely on accurate Gerber files to translate design specifications into physical boards. Understanding the significance of Gerber files fosters seamless communication between designers and manufacturers, streamlining the fabrication process and minimizing errors.

With the competitive landscape in PCB manufacturing, securing competitive prices while maintaining quality is paramount. PCB manufacturers offering fast turnarounds, including 24-hour production cycles, cater to the urgent demands of clients without compromising quality standards. Efficient board design and streamlined production processes reduce lead time, ensuring timely delivery of high-quality PCBs.

Selecting the right PCB manufacturer is a critical decision in the fabrication process. Reputable manufacturers equipped with cutting-edge technology and a track record of excellence ensure the production of top-tier PCBs. Collaborating closely with PCB manufacturers yields benefits such as cost optimization, tailored solutions, and responsive customer service, enhancing the overall fabrication experience.

As technology advances, the landscape of PCB fabrication continues to evolve. Innovations in materials, design tools, and production techniques revolutionize the way PCBs are manufactured. Embracing emerging trends such as sustainable manufacturing practices, flexible electronics, and automated assembly processes sets the stage for the future of PCB fabrication, driving efficiency and sustainability.

Inexpensive PCB fabrication is not merely about cost reduction; it's a strategic approach towards achieving high-quality, cost-effective printed circuit boards. By prioritizing efficient design, leveraging advanced technologies, and collaborating with trusted PCB manufacturers, businesses can navigate the complexities of PCB fabrication successfully. Adaptability, innovation, and a focus on quality underpin the foundation of affordable PCB fabrication, ensuring competitiveness in the dynamic electronics industry.

1. What role do PCB prototypes play in the fabrication process?

PCB prototypes serve as initial models for testing designs and functionalities before full-scale production, allowing for validation and refinement of designs.

2. How crucial are Gerber files in PCB manufacturing?

Gerber files contain essential design information and serve as a blueprint for PCB production, ensuring accuracy and precision in the manufacturing process.

3. How can businesses ensure fast turnaround times for PCB fabrication?

Choosing PCB manufacturers offering expedited services, such as 24-hour production cycles, can help meet urgent project deadlines without compromising quality.

4. What considerations should be made when selecting a PCB manufacturer?

Factors such as technological capabilities, quality standards, pricing competitiveness, and customer service play vital roles in choosing the right PCB manufacturer.

5. What are some emerging trends in PCB fabrication practices?

Emerging trends include sustainable manufacturing practices, flexible electronics, automation in assembly processes, and advancements in materials and design tools, shaping the future of PCB fabrication.