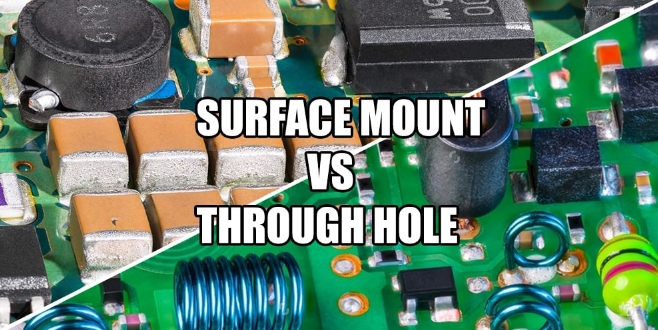

In the world of electronics manufacturing, two major technologies have dominated the landscape: surface mount technology (SMT) and through hole technology. Both approaches have their own strengths and applications, but understanding the differences between them is essential to make informed decisions during the production process. This article aims to provide a comprehensive comparison of SMT and through hole technology, highlighting their advantages, assembly considerations, and cost effectiveness.

What is SMT?

Surface mount technology (SMT), also known as surface mount device (SMD) assembly, is a method of manufacturing electronic devices where components are directly mounted onto the surface of the printed circuit board (PCB). Unlike through hole technology, which uses holes to connect components, SMT relies on the soldering of component leads to the PCB's surface.

Advantages of SMT

SMT offers several advantages over traditional through hole technology. Firstly, it allows for greater component density on PCBs, as surface-mounted components take up less space than their through hole counterparts. This miniaturization enables the creation of smaller and more lightweight electronic devices. Additionally, SMT components typically have shorter leads, reducing the chance of signal interference and improving high-frequency performance.

What is Through Hole Technology?

Through hole technology is a conventional method of assembling electronic components, where the leads of components are inserted into drilled holes on a PCB and then soldered on the opposite side of the board.

Advantages of Through Hole Technology

Through hole technology offers its own set of advantages. One key benefit is enhanced mechanical stability, as components are firmly secured in the drilled holes. This makes through hole technology suitable for applications that may require greater durability, such as in the automotive or aerospace industries. Additionally, through hole assembly allows for easier manual repairs or component replacements, which can be advantageous in certain situations.

Differences in Manufacturing Process

The manufacturing processes for SMT and through hole technology differ significantly. SMT components are mounted directly onto the surface of the PCB, while through hole components require drilled holes for insertion. The soldering techniques used also vary, with SMT utilizing reflow ovens, and through hole technology relying on wave soldering.

Suitability for Different Applications

The choice between SMT and through hole technology depends on the requirements of each specific application. SMT is well-suited for high-speed and high-density applications due to its smaller components and reduced parasitic capacitance. On the other hand, through hole technology is preferred for applications that demand high mechanical strength and reliability.

Assembly Considerations

The assembly process for SMT and through hole technology differs significantly. Surface mount assembly involves precise placement of components onto solder paste, followed by reflow soldering. Through hole assembly, however, requires manual insertion and wave soldering. Furthermore, mixed technology PCBs that combine both SMT and through hole components require additional considerations during assembly.

Cost Effectiveness and Efficiency

When it comes to cost effectiveness, SMT holds an advantage. SMT assembly is highly automated, reducing the need for manual labor. Additionally, the smaller and lighter components used in SMT allow for streamlined production processes. Meanwhile, through hole assembly requires more manual labor and can be time-consuming, leading to increased costs, particularly for complex circuit boards.

Components and Printed Circuit Board (PCB) Assembly

SMT components, such as resistors, capacitors, and integrated circuits, are designed to be mounted directly on the surface of the PCB. This arrangement enables smaller PCB sizes and increased circuit density. The assembly process involves carefully placing components onto solder paste on the PCB, which is then heated in a reflow oven to create a reliable solder joint. This precise assembly technique allows for efficient and accurate manufacturing.

Reflow Soldering and Solder Paste

Reflow soldering is a critical step in SMT assembly. During this process, the PCB is subjected to controlled heating, causing the solder paste to melt and form a strong bond between the components and the PCB. Solder paste, a mixture of tiny metal alloy balls and flux, helps facilitate the soldering process by adhering to the component leads and the PCB pads.

Benefits of Surface Mount Assembly

Surface mount assembly offers numerous benefits. Firstly, it allows for higher assembly speeds, making it suitable for high-volume production. Additionally, the smaller thermal mass of SMT components improves heat dissipation on the PCB, enabling streamlined thermal management. Furthermore, SMT allows for more accurate testing and inspection, ensuring higher manufacturing quality.

Hole Components and Drilled Holes

Through hole technology relies on components with leads specifically designed for insertion into drilled holes on the PCB. This technology permits secure positioning of components, reducing the risk of mechanical stress or damage. The drilled holes, once the components are inserted, are soldered on the opposite side of the board, ensuring robust electrical connections.

Wave Soldering Process

Wave soldering is a key step in through hole assembly. The PCB, with the inserted through hole components, is passed over a wave of molten solder, allowing the solder to flow through the holes and form strong electrical connections on the opposite side of the board. Wave soldering is a time-tested method that ensures reliable solder joints.

Advantages of Through Hole Assembly

Through hole assembly has its own advantages. This technology provides excellent mechanical stability and is more resistant to mechanical stress and vibrations, making it ideal for applications where durability is crucial. Additionally, through hole components are generally easier to replace or repair manually, which can be advantageous during prototyping or when anticipating possible design changes.

Factors to Consider

When deciding between SMT and through hole technology, several factors need to be considered. These include the specific application requirements, the desired level of mechanical stability, the need for manual repairs or replacements, the complexity of the circuit board, and the expected production volumes. Careful evaluation of these factors will guide manufacturers in making the appropriate technology selection.

Application Examples for Each Technology

SMT is commonly used in consumer electronics, mobile devices, telecommunication equipment, and many other compact electronic devices. On the other hand, through hole technology finds applications in industries that require high reliability and robustness, such as automotive, aerospace, and military sectors.

In the world of electronics manufacturing, the choice between surface mount technology and through hole technology is crucial. While SMT offers advantages in terms of component miniaturization and high-speed applications, through hole technology excels in mechanical stability and repairs. Ultimately, the decision lies in understanding the specific requirements of the application and balancing the factors of cost, reliability, and assembly considerations.

Is surface mount technology more cost-effective than through hole technology?

Generally, surface mount technology is more cost-effective due to its automated assembly processes and smaller components, which result in lower labor and material costs. However, for specific applications or small-scale production, through hole technology can be more economical.

Can through hole components be used with surface mount technology?

While through hole components can be used alongside surface mount technology on a mixed technology PCB, it requires additional assembly considerations and can affect the overall efficiency of the manufacturing process.

Is one technology more suitable for high-frequency applications?

Surface mount technology is generally preferred for high-frequency applications due to its smaller component size and reduced parasitic capacitance. However, proper design techniques can allow through hole technology to be suitable for specific high-frequency applications as well.

Are solder joints more reliable with surface mount or through hole technology?

Both surface mount and through hole technologies can provide reliable solder joints. However, through hole technology offers enhanced mechanical stability and can withstand more substantial mechanical stress and vibrations. Surface mount technology excels in smaller-scale and high-speed applications.

Can I mix surface mount and through hole components on the same PCB?

Yes, it is possible to mix surface mount and through hole components on the same PCB. However, this requires careful planning and consideration of assembly processes, design constraints, and manufacturing requirements.