In the realm of electronic engineering, FR4 printed circuit boards (PCBs) have gained immense popularity due to their exceptional mechanical and electrical properties. FR4, which stands for Flame Retardant 4, refers to a standardized grade of PCB material that offers a remarkable balance between mechanical strength, electrical insulation, and flame-retardant capabilities. In this article, we will delve into the world of FR4 PCBs, exploring their composition, advantages, and applications across various industries.

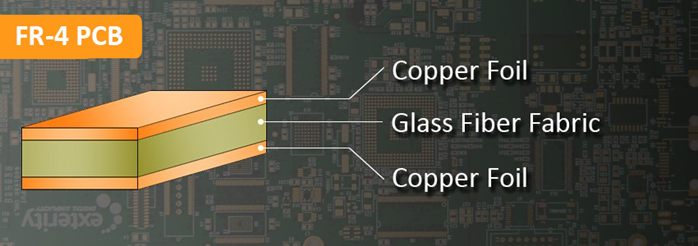

FR4 PCBs are constructed using a layered board design, with FR4 material serving as the base. FR4 is a glass-reinforced epoxy laminate that is known for its outstanding mechanical and electrical properties. The core of an FR4 PCB consists of a reinforced epoxy resin, reinforced with layers of woven glass fabric. This composition results in a PCB material that possesses remarkable strength, durability, and electrical insulation.

The "FR" in FR4 stands for Flame Retardant, highlighting one of the key features of this material. FR4 PCBs are designed to resist and inhibit the spread of flames, making them a safe choice for electronic applications. The FR4 material is manufactured to comply with stringent flame retardancy standards, ensuring that it exhibits excellent self-extinguishing properties. This makes FR4 PCBs a reliable choice for applications where fire safety is crucial.

One of the standout features of FR4 PCBs is their exceptional mechanical strength. The glass reinforcement in FR4 material enhances its strength-to-weight ratio, making it ideal for applications that require robustness without compromising on weight. The layered construction of FR4 PCBs provides structural integrity, allowing them to withstand mechanical stress, shocks, and vibrations. This superior mechanical strength makes FR4 PCBs suitable for applications in industries such as aerospace, automotive, and industrial equipment.

FR4 PCBs are renowned for their excellent electrical insulation properties. The epoxy resin used in FR4 material provides superb insulation, preventing electrical leakage and ensuring reliable performance. FR4 PCBs offer high dielectric strength, allowing them to withstand high voltages without compromising the integrity of the circuit. This makes FR4 PCBs a preferred choice for applications that require precise and stable electrical performance, such as power electronics, telecommunications, and consumer electronics.

While FR4 PCBs offer impressive mechanical and electrical properties, it is important to note their susceptibility to water absorption. The woven glass fabric used in FR4 material can absorb moisture over time, which may impact the electrical performance and reliability of the PCB. Therefore, it is crucial to implement proper moisture protection measures, such as conformal coating or encapsulation, to mitigate the risk of water absorption and ensure long-term reliability.

FR4 PCBs find extensive applications in high-frequency and high-performance systems. The low loss tangent and stable dielectric constant of FR4 material make it well-suited for high-frequency applications, such as RF circuits, microwave devices, and telecommunications equipment. The mechanical strength of FR4 PCBs allows them to withstand the demands of high-performance systems, ensuring consistent and reliable operation even under challenging conditions.

FR4 PCBs play a crucial role in the PCB design and manufacturing process. Their versatility and widespread availability make them a popular choice for a wide range of applications. PCB designers leverage the mechanical and electrical properties of FR4 to create optimized layouts, ensuring efficient signal transmission, thermal management, and component placement. PCB manufacturers utilize FR4 material to fabricate high-quality PCBs with precise specifications, utilizing advanced manufacturing techniques to ensure exceptional performance and reliability.

FR4 printed circuit boards have revolutionized the world of electronics with their unmatched combination of mechanical strength, electrical insulation, and flame-retardant properties. The FR4 material, with its reinforced epoxy laminated structure, provides a solid foundation for designing and manufacturing high-performance PCBs. From their role in high-frequency applications to their contribution to PCB design and manufacturing, FR4 PCBs have become an indispensable component in the world of electronics. As technology continues to advance, FR4 PCBs will undoubtedly continue to evolve, enabling new innovations and shaping the future of electronic engineering.