In the rapidly evolving landscape of electronics devices, innovation is not just about adding new features; it's also about optimizing space, reducing weight, and enhancing durability without compromising functionality. One pivotal technology that has significantly contributed to this evolution is the custom flexible PCB (printed circuit board), or flex cable. These marvels of engineering have transformed the way we design and manufacture electronic devices, enabling sleeker form factors, robust performance, and unprecedented adaptability.

Flexible PCBs, often referred to as flex boards, are thin, lightweight circuits designed to bend and twist while maintaining their electrical integrity. Unlike traditional rigid PCBs, which are made of solid substrate materials like fiberglass, flex boards use flexible substrates such as polyimide, allowing them to conform to intricate shapes and tight spaces. This unique characteristic opens up a realm of possibilities for electronics devices, making them indispensable in sectors ranging from consumer electronics to aerospace and medical equipment.

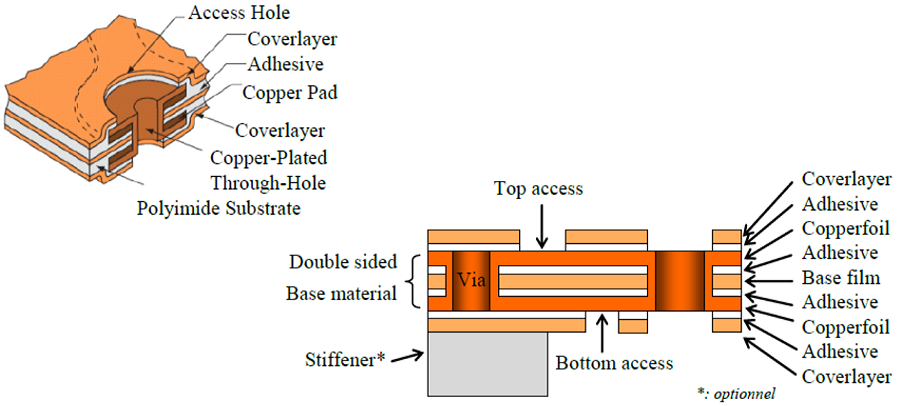

Flexible printed circuits come in various forms, including single-sided flex, double-sided, and multilayer configurations. Single-sided flex PCBs have conductive traces on one side only, suitable for simple designs requiring flexibility. Double-sided flex boards feature copper traces on both sides, connected through plated-through holes, offering increased complexity and versatility. Multilayer flex PCBs, on the other hand, incorporate multiple layers of conductive traces separated by insulating materials, enabling high-density designs for complex applications.

A key aspect of designing flexible circuits is controlled impedance, which ensures signals travel at consistent speeds, minimizing signal loss and crosstalk. This is particularly crucial in high-speed data transmission applications such as in smartphones and wearable technology.

Rigid-flex PCBs take flexibility a step further by combining rigid and flexible sections within a single circuit board. This hybrid approach allows designers to optimize space and weight while providing the mechanical stability necessary for components that require mounting. Rigid-flex circuits are ideal for application requirements demanding compactness, such as in satellite systems or portable medical devices, where every millimeter of space counts.

The primary advantage of flexible PCBs lies in their ability to save space and reduce weight. In industries where miniaturization is paramount, like aerospace and wearable tech, flex cables facilitate the creation of thinner, lighter devices without sacrificing performance. By eliminating bulky connectors and wiring harnesses, flexible circuits streamline device assembly, contributing to overall cost-effectiveness and reliability.

Despite the initial perception that flexible circuits may be costlier due to their specialized manufacturing process, they often prove to be more cost-effective in the long run. The reduction in assembly time, elimination of connector components, and minimized risk of errors during installation can lead to significant savings. Moreover, the durability and reliability of flex PCBs reduce repair and replacement costs, making them a wise investment for high-volume production runs.

Designing flexible circuits requires a nuanced understanding of material properties, circuit design, and the end product's application environment. Engineers must consider factors such as bend radius, folding patterns, and the number of flex cycles a design will endure. Advanced software tools aid in simulating stress points and optimizing trace layouts to ensure optimal performance under bending conditions.

The versatility of flexible PCBs finds expression in a myriad of applications across various industries. From the intricate folds of a smartwatch strap to the complex circuitry within a drone's camera system, flexible printed circuits are enabling innovations that were once unimaginable. In medical devices, they facilitate the creation of minimally invasive surgical tools and wearable health monitors. In automotive, they contribute to the development of safer, more efficient vehicles by integrating seamlessly into compact spaces.

Custom flexible PCB printed circuit boards, with their unique blend of adaptability, efficiency, and durability, are reshaping the electronics industry's future. As technology pushes the boundaries of what's possible, the role of flex and rigid-flex circuits becomes increasingly vital. By addressing the challenges of space constraints, weight reduction, and complex design requirements, these innovative circuits are unlocking new frontiers in electronic device design. As we continue to explore the potential of flexible electronics, one thing is clear: the future of electronics devices is flexible, and it's here to stay.

1. What is the difference between a flexible PCB and a standard rigid PCB?

Standard rigid PCBs are made from inflexible materials like fiberglass, while flexible PCBs utilize flexible substrates such as polyimide. This flexibility allows them to be bent, folded, or twisted to fit into tight spaces, making them ideal for compact devices where rigidity would be a limitation. Additionally, flexible PCBs can reduce the need for connectors and wires, leading to lighter and more reliable assemblies.

2. Are flexible PCBs more expensive than rigid PCBs?

Initially, flexible PCBs might have a higher unit cost due to the specialized materials and manufacturing processes involved. However, when considering the total cost of ownership, flexible PCBs can be more cost-effective. They reduce assembly time, minimize the need for additional components like connectors, and enhance reliability, which can lower maintenance and repair expenses over time.

3. Can flexible PCBs handle high-frequency signals?

Yes, flexible PCBs can be designed for high-frequency applications by implementing controlled impedance features. This involves precise calculations and manufacturing techniques to ensure that the electrical signals travel along the traces at a consistent speed, minimizing signal degradation, crosstalk, and electromagnetic interference (EMI).

4. How do you decide between using single-sided, double-sided, or multilayer flexible PCBs?

The choice depends on the complexity and specific requirements of your application. Single-sided flex PCBs are suitable for simpler designs with less wiring density. Double-sided boards allow for more complex routing and can accommodate components on both sides. Multilayer flex PCBs are used for highly complex designs requiring multiple signal layers or enhanced electrical shielding, typically found in advanced electronics like satellite communication systems.

5. How does one ensure the durability of flexible PCBs during repeated bending?

Durability in flexible PCBs is ensured by careful design considerations such as selecting the appropriate substrate material, determining the minimum bend radius that the circuit can withstand without damage, and incorporating strain relief features. Additionally, choosing materials with good fatigue resistance and designing with adequate space for flexing can significantly enhance the longevity of the circuit under repetitive bending conditions.

6. Are flexible PCBs suitable for harsh environments?

Absolutely. Flexible PCBs can be designed with protective coatings and encapsulation materials to withstand harsh environmental conditions such as high temperatures, moisture, chemicals, and vibrations. This makes them suitable for applications in aerospace, military, and industrial settings where reliability under extreme conditions is critical.

7. How does the design process differ for rigid-flex PCBs compared to standard flexible PCBs?

Designing rigid-flex PCBs introduces additional complexity because it involves integrating both rigid and flexible sections in a single layout. Designers must carefully plan transitions between rigid and flexible areas, ensuring proper layer alignment, and accounting for different thermal expansion coefficients of materials. Specialized software is often used to simulate and optimize the design for both mechanical and electrical performance.

8. Can flexible PCBs be repaired or modified once they are produced?

Repairing or modifying flexible PCBs after production can be challenging due to their delicate nature. While minor repairs might be feasible with specialized techniques, major changes are often impractical or uneconomical. Therefore, thorough design verification and testing upfront are essential to minimize the need for post-production modifications.