In the rapidly evolving landscape of electronics manufacturing, Surface Mount Technology (SMT) and its resulting components, Surface Mount Devices (SMDs), have undeniably reshaped the industry's approach to Printed Circuit Board (PCB) assembly. This innovative technology, which facilitates mounting electronic components directly onto the surface of a PCB without drilling holes, has opened new avenues for high-density, compact designs that were once unimaginable with traditional hole technology. This article delves into the world of SMT SMD components, exploring their impact on PCB assembly, their advantages over hole components, and the intricate processes involved in their application.

Before SMT, electronic components were primarily mounted using through-hole technology, a method where leads of components穿透 the PCB and were soldered on the opposite side. While reliable, this technique limited the miniaturization potential and overall efficiency of electronic assemblies. Enter SMT, a game-changing approach that not only allows for smaller components but also significantly speeds up the assembly process, enhancing productivity and enabling the production of high-quality, compact electronic devices.

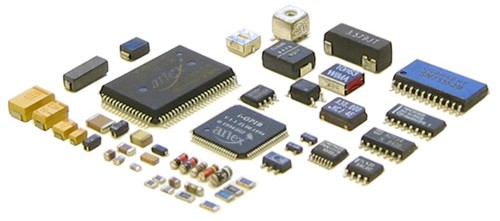

At the heart of SMT lies Surface Mount Devices (SMDs), electronic components designed to be mounted directly onto the PCB surface. These components come in various forms, including resistors, capacitors, transistors, Integrated Circuits (ICs), and many more, all tailored to fit snugly on the PCB without the need for drilled holes. Their small sizes and lightweight nature facilitate the creation of incredibly dense circuits, a critical factor behind the miniaturization trend seen in today’s smartphones, wearables, and other portable electronics.

1. Smaller Components, Greater Density: SMDs enable a substantial reduction in the size of electronic devices, making them ideal for compact applications where space is at a premium.

2. Faster Assembly: Automated pick and place machines can swiftly and accurately position SMDs on PCBs, significantly speeding up the manufacturing process compared to manual insertion of through-hole components.

3. Enhanced Reliability: Solder joints in SMT assemblies tend to be more consistent and reliable due to the controlled environment of the reflow oven, reducing the risk of defects and improving product lifespan.

4. Cost Efficiency: The combination of smaller components and automated assembly reduces material costs and labor time, translating to cost savings for manufacturers.

The SMT process is a meticulously choreographed dance of precision and efficiency. It typically involves the following stages:

1. PCB Preparation: Before any components are placed, the PCB undergoes cleaning and application of solder paste, a mixture of minute solder particles and flux, at predefined locations using a stencil or printing machine.

2. Component Placement: Using highly accurate automated pick and place machines, SMDs are picked from reels or trays and precisely positioned onto the solder paste-coated pads on the PCB.

3. Reflow Soldering: The populated PCB then enters a reflow oven, where the solder paste is heated to its melting point, forming strong, uniform solder joints as it cools and solidifies. This step effectively bonds the components to the PCB surface.

4. Inspection and Testing: Post-soldering, visual and automated inspections are carried out to ensure the quality of solder joints and correct placement of components. Functional testing may also be performed to verify the assembled PCB's performance.

The advent of SMT and SMDs has had profound implications for the electronics industries. It has fueled innovation by enabling the design of smaller, lighter, and more complex devices that meet the ever-increasing demands for portability and functionality. This technology has not only streamlined manufacturing processes but also paved the way for advancements in sectors like telecommunications, automotive, aerospace, and consumer electronics.

Surface Mount Technology and its SMD components have undeniably marked a turning point in the evolution of electronics manufacturing. By allowing for smaller sizes, higher quality, and faster production rates, SMT has become the cornerstone of modern PCB assembly. As technology continues to advance, pushing the boundaries of miniaturization and performance, SMT and SMDs will undoubtedly remain at the forefront, driving innovation and shaping the future of electronics.

1. What is the primary difference between Surface Mount Technology (SMT) and Through-Hole Technology?

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of a PCB, while Through-Hole Technology requires components to be inserted into drilled holes and soldered on the opposite side. SMT supports smaller components and denser circuit designs, leading to more compact and efficient electronic devices.

SMDs facilitate faster manufacturing because they can be placed onto PCBs using automated pick and place machines. These machines work at high speeds, accurately positioning components in a fraction of the time it would take for manual insertion used in through-hole technology.

Solder joints in SMT are formed under controlled conditions in a reflow oven, ensuring even heating and cooling, which results in consistent and robust connections. This process minimizes the likelihood of cold solder joints or other defects commonly associated with manual soldering.

4. Can all electronic components be mounted using SMT?

While a vast majority of modern electronic components are designed for SMT, there are still some specialized components, particularly those requiring high mechanical strength or heat dissipation, that may still use through-hole technology. However, advancements continue to push more components towards SMT compatibility.

A stencil, also known as a solder paste stencil, is a thin metal sheet with apertures that match the pattern of solder pads on the PCB. It is used to apply solder paste precisely onto the PCB before component placement. The stencil ensures an accurate and consistent amount of solder paste at each connection point, vital for successful soldering.

6. How does the inspection process work in SMT assembly?

Inspection in SMT assembly includes both visual checks and automated optical inspection (AOI). Visual inspection by trained personnel can catch obvious defects, while AOI systems use cameras and software algorithms to analyze solder joints and component placement, identifying issues such as missing components, misalignments, or insufficient solder. In some cases, X-ray inspection may also be employed to inspect hidden joints beneath components.

7. Are SMT assemblies suitable for high-reliability applications?

Absolutely. SMT assemblies are widely used in high-reliability applications like aerospace, medical devices, and military equipment due to their consistent quality, durability, and ability to withstand harsh environments. Rigorous testing and quality control measures ensure that SMT assemblies meet stringent reliability standards.

8. Can SMT components be repaired or replaced if they fail after assembly?

While replacing or repairing SMT components post-assembly can be challenging due to their small size and direct mounting, it is possible with specialized tools and techniques. Techniques like rework stations equipped with hot air guns and micro-soldering tools allow skilled technicians to remove and replace faulty SMDs without damaging the PCB or surrounding components. However, prevention through rigorous quality control remains the preferred approach.