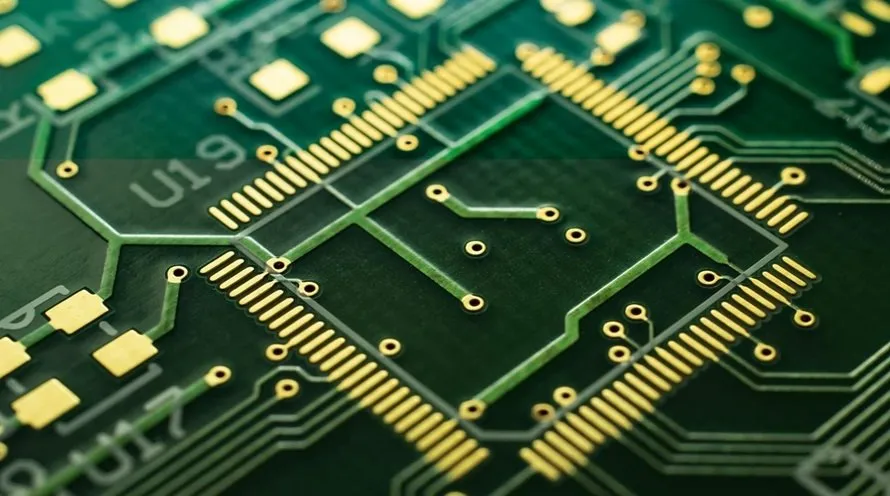

In the ever-evolving world of electronics, the journey from an idea to a market-ready product often begins with a prototype PCB (Printed Circuit Board). These essential tools allow engineers and designers to test and refine their concepts before committing to full-scale production. This article delves into the significance of prototype PCBs, their features, benefits, and applications, while also addressing common questions about their use.

A prototype PCB is a preliminary version of a printed circuit board used to validate the design and functionality of an electronic circuit. It serves as a crucial step in the development process, enabling designers to identify and correct any issues before moving to mass production. Prototype PCBs are indispensable in ensuring that the final product is both functional and reliable.

Prototype PCBs come in various configurations, ranging from single-layer to multi-layer PCBs. Multi-layer PCBs are particularly useful in complex designs where space is limited, as they allow for more intricate routing of electrical connections.

One of the most significant advantages of prototyping PCBs is the availability of quick turn services. These services expedite the production of prototype PCBs, allowing designers to receive their boards in a matter of days. This rapid turnaround is essential for meeting tight project deadlines and accelerating the development process.

Despite being prototypes, these PCBs are manufactured to high quality standards. This ensures that the prototypes closely mimic the performance of the final product, providing accurate insights into the design's functionality and reliability.

Prototype PCBs are designed with cost effectiveness in mind. By identifying and resolving issues early in the design process, they help avoid costly mistakes in the final production run. Additionally, producing a small batch of prototype PCBs is generally more affordable than manufacturing a full production run.

Prototype PCBs allow designers to validate their designs before committing to full-scale production. This step is crucial in ensuring that the final product functions as intended and meets all design specifications.

By testing a prototype PCB, designers can identify and address potential issues early in the development process. This proactive approach helps prevent costly redesigns and delays in the final production phase.

Prototyping enables an iterative design process, where multiple versions of a PCB can be tested and refined. This continuous improvement cycle leads to a more polished and reliable final product.

Prototype PCBs can be shared with customers and stakeholders for feedback. This input is invaluable in refining the design to better meet user needs and expectations.

Using prototype PCBs helps mitigate risks associated with new product development. By thoroughly testing and validating the design, companies can reduce the likelihood of product failures and recalls.

Prototype PCBs are widely used in the development of consumer electronics, such as smartphones, tablets, and wearable devices. These prototypes help ensure that the final products are both functional and user-friendly.

In the automotive industry, prototype PCBs play a crucial role in the development of advanced driver-assistance systems (ADAS), infotainment systems, and other electronic components. These prototypes help engineers validate the performance and reliability of their designs.

Medical device manufacturers rely on prototype PCBs to develop and test new devices, such as diagnostic equipment, monitoring systems, and wearable health trackers. Ensuring the accuracy and reliability of these devices is critical for patient safety.

Prototype PCBs are used in the development of industrial automation systems, including robotics, control systems, and sensors. These prototypes help ensure that the final products meet the stringent requirements of industrial applications.

In the telecommunications industry, prototype PCBs are essential for developing and testing communication devices, such as routers, switches, and base stations. These prototypes help ensure that the devices deliver reliable and high-quality performance.

Before creating a prototype PCB, thoroughly plan your design. Consider the layout, component placement, and routing to ensure a clean and efficient design.

Select the appropriate layer PCB configuration for your design. Multi-layer PCBs are ideal for complex designs with limited space, while single-layer PCBs are suitable for simpler projects.

Take advantage of quick turn services to expedite the prototyping process. This will help you meet tight deadlines and accelerate your development timeline.

Conduct comprehensive testing on your prototype PCB to identify and address any issues. Use tools such as oscilloscopes, multimeters, and logic analyzers to verify the functionality of your design.

Share your prototype PCB with stakeholders and gather feedback. Use this input to refine your design and ensure it meets user needs and expectations.

A prototype PCB is a preliminary version used to test and validate a design, while a production PCB is the final version used in the mass production of the product. Prototype PCBs help identify and resolve issues before committing to full-scale production.

With quick turn services, you can receive a prototype PCB in as little as a few days. The exact turnaround time depends on the complexity of the design and the capabilities of the manufacturer

Yes, prototype PCBs are manufactured to high quality standards to ensure they accurately represent the performance of the final product. This helps provide reliable insights during the testing and validation process.

While prototype PCBs are primarily used for testing and validation, they can sometimes be used for small batch production. However, for larger scale production, it's recommended to design a custom PCB that meets the specific requirements of your project.

Prototype PCBs are generally cost-effective, as they help identify and resolve issues early in the design process, preventing costly mistakes in the final production run. Additionally, producing a small batch of prototype PCBs is more affordable than manufacturing a full production run.

The number of layers for your prototype PCB depends on the complexity of your design. Simple designs may only require a single-layer PCB, while more complex designs may benefit from multi-layer PCBs to accommodate intricate routing.

Prototype PCBs are an essential tool in the electronics development process, providing a platform for testing, validation, and refinement. With features such as layer PCB options, quick turn services, and high quality standards, these PCBs help ensure that the final product is both functional and reliable. By incorporating prototype PCBs into your development process, you can reduce risks, improve design quality, and accelerate your time to market. Whether you're working on consumer electronics, automotive systems, medical devices, industrial automation, or telecommunications, prototype PCBs are the cornerstone of successful electronics innovation.