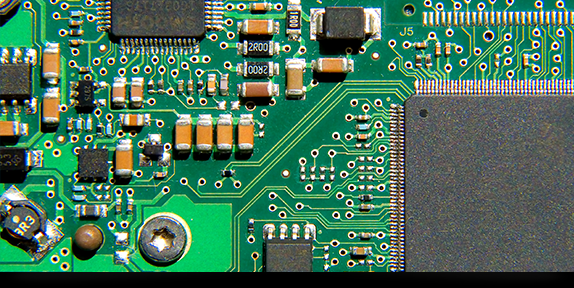

When it comes to assembling printed circuit boards (PCBs), efficiency and precision are paramount. One tool that significantly enhances the assembly process is the PCB stencil. This article explores the benefits of using stencils for PCB assembly, the different types available, and how they can save you time and effort. We’ll also address common questions about PCB stencils to help you make informed decisions.

A PCB stencil is a thin sheet, often made of stainless steel, used to apply solder paste to the surface mount pads on a PCB. The stencil has openings that correspond to the pads on the PCB, allowing the solder paste to be accurately deposited in the right places. This process is crucial for ensuring that surface mount components are correctly positioned and securely soldered to the PCB.

Laser cut SMT stencils are manufactured using precision laser cutting technology. These stencils are known for their accuracy and clean edges, which ensure precise application of solder paste. The laser cutting process allows for the creation of intricate and detailed designs, making these stencils ideal for complex PCB layouts.

Framed stencils are mounted on a frame, providing stability and ease of handling. These stencils are specifically designed for use in high-volume production environments where consistency and repeatability are essential. The frame ensures that the stencil remains flat and aligned with the PCB during the solder paste application process.

Stencil kits typically include everything needed for manual solder paste application, such as the stencil itself, a squeegee blade, and board holders. These kits are particularly useful for small-scale production and prototyping, as they provide a complete solution for the solder paste application process.

Using a stencil for PCB assembly can significantly reduce the time required to assemble a prototype. By allowing you to quickly and accurately apply solder paste to the PCB, stencils eliminate the need for tedious hand soldering, speeding up the overall assembly process.

Hand soldering each component on a PCB can be a time-consuming and error-prone task. Stencils are specifically designed to eliminate this tedious process by ensuring that solder paste is applied precisely where it is needed. This not only saves time but also improves the quality and reliability of the assembled PCB.

The precision of laser cut SMT stencils ensures that solder paste is applied accurately to each pad on the PCB. This accuracy is crucial for achieving reliable solder joints and preventing issues such as solder bridges and insufficient solder.

Using a stencil for PCB assembly is easier and saves you time compared to manual solder paste application. The stencil allows you to apply solder paste to all pads simultaneously, rather than having to manually apply paste to each pad individually. This streamlined process reduces the likelihood of errors and speeds up assembly.

PCB stencils are versatile and can be used for a wide range of PCB designs and applications. They are also cost-effective, particularly for prototyping and small-scale production runs. By improving the efficiency and accuracy of the assembly process, stencils help reduce overall production costs.

Using a PCB stencil involves several steps:

Place the PCB on a flat surface and align the stencil with the pads on the PCB. Ensure that the stencil is properly positioned so that the openings align with the pads.

If you are using a framed stencil, the frame will help keep the stencil in place. For non-framed stencils, use board holders or other tools to secure the stencil and prevent it from moving during the solder paste application process.

Using a squeegee blade, spread solder paste across the stencil, ensuring that it fills the openings. Apply even pressure to ensure that the paste is evenly distributed and properly applied to the pads on the PCB.

Carefully lift the stencil away from the PCB, ensuring that the solder paste remains on the pads. Inspect the PCB to ensure that the paste has been applied correctly and that there are no smudges or misalignments.

Once the solder paste has been applied, place the surface mount components on the PCB. After placing the components, use a reflow oven, such as a toaster reflow oven, to heat the PCB and melt the solder paste, creating secure solder joints.

A PCB stencil is used to apply solder paste to the pads on a PCB accurately. This ensures that surface mount components are correctly positioned and securely soldered to the PCB.

Choose a stencil based on the complexity of your PCB design and your production needs. Laser cut SMT stencils are ideal for precise and intricate designs, while framed stencils are suitable for high-volume production. Stencil kits are a good option for small-scale production and prototyping.

Yes, a toaster reflow oven can be used for reflow soldering. It is a cost-effective solution for small-scale production and prototyping, allowing you to achieve reliable solder joints without the need for expensive reflow ovens.

Yes, PCB stencils can be reused multiple times, provided they are properly cleaned and maintained. Regular cleaning helps ensure that the stencil remains free of solder paste residue and maintains its accuracy.

A stencil kit typically includes the stencil itself, a squeegee blade, and board holders. Some kits may also include additional tools and accessories to facilitate the solder paste application process.

Many manufacturers offer a money back guarantee program for their stencils. This ensures that you can purchase with confidence, knowing that you can return the stencil if it does not meet your expectations.

Stencils for PCB assembly are invaluable tools that simplify the process of applying solder paste to PCBs. They are specifically designed to reduce PCB prototype assembly time, eliminate tedious hand soldering, and improve the accuracy of solder paste application. Whether you are working on a small-scale prototype or a high-volume production run, using a PCB stencil can save you time, effort, and cost. By choosing the right stencil for your needs and following best practices for solder paste application, you can achieve reliable and high-quality PCB assemblies.