In the world of printed circuit board (PCB) assembly, precision is crucial. One of the key elements that contribute to this precision is the use of fiducial marks. This article delves into the importance of fiducial marks in PCB design and assembly, explaining their functions, types, and best practices for their placement.

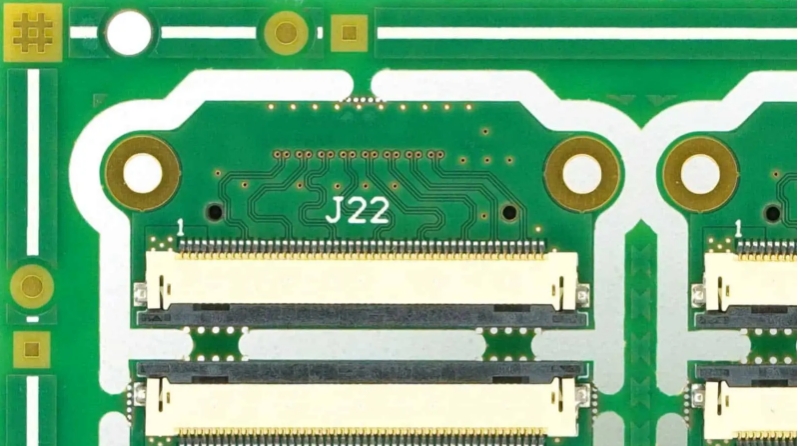

A fiducial mark, also known as a fiducial marker, is a reference point on a PCB that helps automated assembly machines accurately locate and align the board. These marks are essential for ensuring that surface mount components are placed correctly, leading to reliable and functional PCBs.

Global fiducials are placed on the corners of the board and are used by assembly machines to recognize the overall orientation and position of the PCB. These fiducials provide a reference for the entire board, ensuring that all components are placed accurately relative to the board’s edges.

Local fiducials are placed near specific areas or components on the PCB. They help in the precise placement of individual components, especially when dealing with high-density or complex layouts. Local fiducials are particularly useful for ensuring the accurate alignment of critical components.

Fiducial marks play a crucial role in achieving accurate alignment during PCB assembly. Automated machines use these marks to precisely locate the PCB, ensuring that components are placed correctly. This accuracy is vital for the functionality and reliability of the finished PCB.

The placement of fiducials directly affects component placement. By providing reference points, fiducial marks help pick and place machines accurately position surface mount components on the PCB. This reduces the risk of misalignment and defects.

Modern PCB assembly relies heavily on automated machines. These machines recognize fiducial marks to align the PCB and ensure precise component placement. Without fiducials, the accuracy of automated assembly would be significantly compromised.

Fiducial marks are typically located on the top and bottom copper layers of the PCB. This ensures that both sides of the board can be accurately aligned and assembled. The placement of fiducials on the bottom copper layers is especially important for double-sided PCBs.

When adding fiducials to a PCB design, it is important to place them in strategic locations. For global fiducials, place them at the corners of the board. For local fiducials, place them near critical components or areas with high component density.

The size and shape of fiducial marks should be consistent and easily recognizable by assembly machines. A common shape is a solid circle with a diameter of 1mm to 3mm. Ensure that the fiducial marks are free from any solder mask or silkscreen overlay.

Maintain a clear area around fiducial marks to avoid interference from other PCB elements. A clearance of at least 1mm around the fiducial mark is recommended. This ensures that the fiducial is easily identifiable by automated machines.

Fiducial marks should be included in both the top and bottom copper layers of the PCB. This is especially important for double-sided boards, as it ensures accurate alignment for components on both sides.

A fiducial mark serves as a reference point for automated assembly machines, helping them accurately locate and align the PCB. This ensures precise placement of surface mount components and improves the overall reliability of the assembled board.

Global fiducials should be placed at the corners of the board, while local fiducials should be placed near critical components or high-density areas. Ensure that there is sufficient clearance around each fiducial mark.

Yes, fiducial marks should be placed on both the top and bottom copper layers of the PCB. This ensures accurate alignment for double-sided boards and improves the overall assembly process.

Fiducial marks are typically solid circles with a diameter of 1mm to 3mm. The size should be consistent and easily recognizable by automated assembly machines.

While not all PCBs require fiducial marks, they are highly recommended for boards with surface mount components and those that rely on automated assembly. Fiducial marks improve the accuracy and reliability of the assembly process.

Fiducial marks are an essential component of modern PCB design and assembly. By providing reference points for automated machines, they ensure accurate alignment and precise component placement. Whether you are designing a simple single-sided PCB or a complex multi-layer board, incorporating fiducial marks can significantly enhance the quality and reliability of your assembly process. By following best practices for the placement and design of fiducial marks, you can achieve optimal results and streamline your PCB assembly workflow.