In the fast-paced world of electronics, time is of the essence. Companies need to get their products to market as quickly as possible to stay competitive. This is where fast turn circuit board assembly comes into play. With quick turnaround times and efficient processes, businesses can significantly reduce their time to market. In this article, we will explore the importance of quick turn PCB assembly, the services available, and best practices to ensure a smooth and speedy assembly process.

Time to market is a critical factor in the success of any electronic product. The faster a product can be developed, tested, and launched, the better its chances of capturing market share. Quick turn PCB assembly helps businesses meet tight deadlines and respond swiftly to market demands.

By reducing lead times and accelerating the product development cycle, companies can gain a competitive edge. Quick turnaround PCB assembly allows businesses to introduce new products and innovations faster than their competitors.

In today's dynamic market, the ability to quickly adapt to changes is crucial. Whether it's a design modification or a new feature, quick turn PCB prototypes enable rapid iterations and adjustments, ensuring that the final product meets customer expectations.

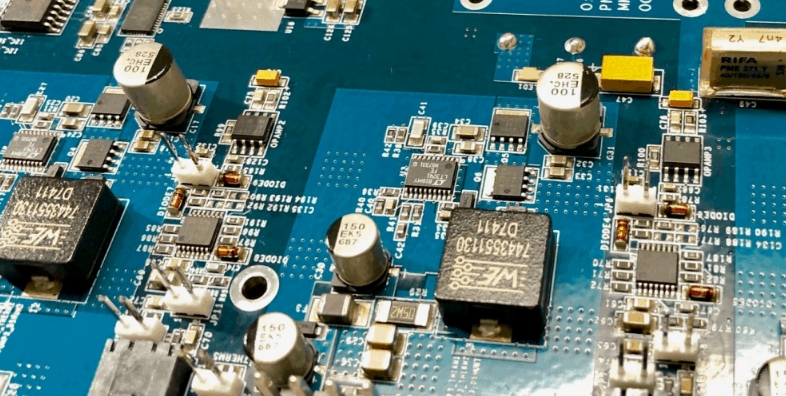

Quick turn PCB assembly refers to the expedited process of assembling printed circuit boards (PCBs) in a significantly shorter time frame than traditional methods. This involves rapid PCB fabrication, efficient assembly processes, and streamlined logistics to deliver fully assembled boards in as little as 24 hours.

The foundation of quick turn PCB assembly lies in efficient PCB fabrication. State-of-the-art manufacturing facilities use advanced technologies and automated processes to produce high-quality PCBs quickly. This includes precise drilling, accurate layer alignment, and reliable solder mask application.

The assembly process is optimized to minimize delays and maximize efficiency. This involves automated pick-and-place machines, high-speed soldering techniques, and thorough quality control measures. By leveraging modern assembly capabilities, manufacturers can significantly reduce assembly time.

Good customer service is essential for quick turn PCB assembly. Providers must communicate effectively with customers, understand their specific requirements, and provide timely updates throughout the assembly process. This ensures that any issues are promptly addressed, and the project stays on track.

State-of-the-art assembly capabilities are crucial for quick turn PCB assembly. This includes the ability to handle complex designs, high component densities, and various soldering techniques. Advanced inspection and testing equipment also play a vital role in ensuring the quality and reliability of the assembled boards.

Quick turn PCB assembly services significantly reduce lead times, allowing companies to move from design to production in a matter of days. This is particularly beneficial for time-sensitive projects and urgent prototyping needs.

By outsourcing PCB assembly to specialized providers, businesses can focus on other critical aspects of product development, such as design, testing, and marketing. This improves overall time management and resource allocation.

While quick turn PCB assembly services may come at a premium, the overall cost savings can be substantial. Faster turnaround times mean shorter development cycles, reduced labor costs, and quicker revenue generation.

Reputable quick turn PCB assembly providers use state-of-the-art equipment and adhere to strict quality standards. This ensures that the assembled boards are of high quality and meet the required specifications.

Effective communication with your PCB assembly provider is crucial. Clearly convey your requirements, timelines, and any specific instructions. Regular updates and feedback are essential to ensure that the project progresses smoothly.

Provide detailed documentation, including schematic diagrams, bill of materials (BOM), assembly drawings, and any other relevant information. This helps the assembly team understand your design and requirements, reducing the risk of errors and delays.

Design your PCBs with manufacturability in mind. This involves considering factors such as component placement, trace routing, and soldering techniques. A DFM approach can significantly reduce assembly time and improve the overall quality of the finished product.

Choose a reliable and experienced quick turn PCB assembly provider. Look for providers with a proven track record, advanced capabilities, and excellent customer service. Read reviews and ask for references to ensure that you are partnering with a trustworthy company.

Quick turn PCB assembly is an expedited process of assembling printed circuit boards in a significantly shorter time frame than traditional methods. This involves rapid PCB fabrication, efficient assembly processes, and streamlined logistics to deliver fully assembled boards quickly.

Quick turn PCB assembly can be completed in as little as 24 hours, depending on the complexity of the design and the capabilities of the assembly provider.

The benefits of quick turn PCB assembly include reduced lead times, improved time management, cost savings, and high-quality results. It allows businesses to get their products to market faster and respond swiftly to market demands.

When choosing a quick turn PCB assembly provider, consider factors such as their experience, assembly capabilities, customer service, and track record. Look for providers with state-of-the-art equipment and a proven ability to deliver high-quality results quickly.

To ensure a smooth quick turn PCB assembly process, communicate clearly with your provider, provide detailed documentation, design for manufacturability, and partner with a reliable provider. Regular updates and feedback are also essential to keep the project on track.

Fast turn circuit board assembly is a game-changer for companies looking to reduce their time to market and stay competitive. By leveraging quick turn PCB assembly services, businesses can achieve rapid development cycles, high-quality results, and significant cost savings. By following best practices and partnering with reliable providers, you can ensure a smooth and efficient assembly process, bringing your innovative products to market faster than ever before.