In the ever-evolving field of electronics, RF (Radio Frequency) circuit card assembly stands out as a specialized area that demands precision, skill, and cutting-edge technology. RF circuits play a critical role in a wide range of applications, from telecommunications to medical devices. This article delves into the intricacies of RF circuit card assembly, exploring the technology, processes, and best practices that ensure high-quality and optimal performance.

RF circuit card assembly involves the creation of printed circuit boards (PCBs) that can handle high-frequency signals. These PCBs are integral to the functioning of devices that rely on radio frequency signals for communication and other purposes. The assembly process is complex, requiring a deep understanding of electrical properties and meticulous attention to detail.

The foundation of any RF circuit card assembly lies in the PCB design. A well-designed PCB ensures that the high-frequency signals are transmitted with minimal loss and interference. This involves careful consideration of the layout, materials, and components used. The design must account for factors such as impedance matching, signal integrity, and thermal management to achieve optimal performance.

One of the primary challenges in RF circuit card assembly is managing high-speed and high-frequency signals. These signals are susceptible to interference and signal degradation, which can impact the performance of the final product. To overcome these challenges, engineers must employ state-of-the-art techniques and technologies.

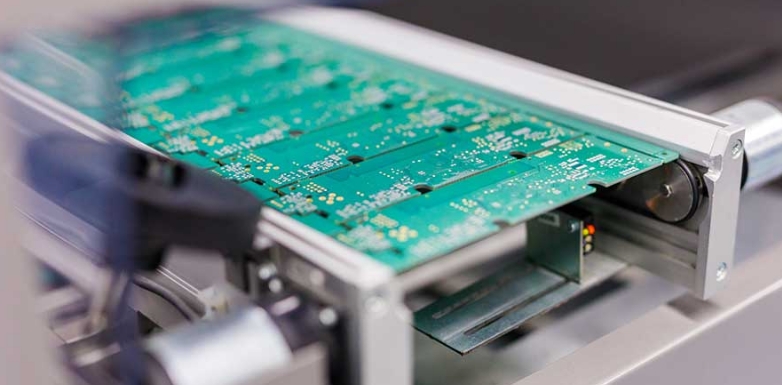

The manufacturing process for RF circuit card assembly involves several stages, each critical to ensuring the quality and performance of the final product. Let's explore these stages in detail.

Surface mount technology (SMT) assembly is a cornerstone of modern PCB manufacturing. In SMT assembly, electronic components are mounted directly onto the surface of the PCB, rather than being inserted into holes. This allows for a more compact and efficient design, which is essential for high-frequency applications.

The placement of components is another crucial aspect of RF circuit card assembly. Components such as grid arrays must be positioned with high precision to ensure proper functionality. Advanced machines are used to place these components accurately, minimizing the risk of errors and ensuring high-quality assembly.

Soldering is a critical step in the manufacturing process, as it creates the electrical connections between components and the PCB. For RF circuit card assembly, both wave soldering and reflow soldering techniques are commonly used. These methods ensure strong and reliable connections, which are essential for handling high-frequency signals.

Quality control is paramount in RF circuit card assembly. Rigorous testing is conducted at various stages of the manufacturing process to identify and rectify any defects. This includes testing for electrical properties, signal integrity, and overall performance. Ensuring high-quality assembly is essential for achieving optimal performance in high-frequency applications.

In the world of RF circuit card assembly, staying ahead of the curve requires the use of cutting-edge technology. This includes advanced PCB design software, precision manufacturing equipment, and state-of-the-art testing tools. By leveraging these technologies, manufacturers can produce high-quality RF circuits that meet the demands of today's high-speed, high-frequency applications.

High mix manufacturing refers to the ability to produce a wide variety of products in small quantities. This is particularly important in RF circuit card assembly, where different applications may require unique designs and components. High mix manufacturing allows for greater flexibility and customization, ensuring that each RF circuit meets the specific needs of its intended application.

Achieving optimal performance in RF circuit card assembly requires a combination of expertise, precision, and advanced technology. By focusing on key factors such as PCB design, component placement, and quality control, manufacturers can produce RF circuits that deliver exceptional performance in high-frequency applications.

Understanding and managing the electrical properties of the PCB is crucial for maintaining signal integrity. This involves careful consideration of factors such as impedance, capacitance, and inductance. By optimizing these properties, engineers can ensure that the high-frequency signals are transmitted with minimal loss and interference.

Thermal management is another important aspect of RF circuit card assembly. High-frequency signals can generate significant heat, which can impact the performance and reliability of the PCB. Effective thermal management techniques, such as the use of heat sinks and thermal vias, help dissipate heat and maintain optimal operating conditions.

As technology continues to advance, the field of RF circuit card assembly is poised for further innovation. Emerging technologies such as 5G, the Internet of Things (IoT), and advanced medical devices will drive the demand for even more sophisticated RF circuits. By staying at the forefront of these developments, manufacturers can continue to deliver high-quality, high-performance RF circuits that meet the evolving needs of the industry.

RF circuit card assembly involves the creation of printed circuit boards (PCBs) that handle high-frequency signals. These PCBs are used in devices that rely on radio frequency signals for communication and other purposes.

PCB design is crucial because it ensures that high-frequency signals are transmitted with minimal loss and interference. A well-designed PCB accounts for factors such as impedance matching, signal integrity, and thermal management.

High-speed and high-frequency signals are susceptible to interference and signal degradation. Managing these challenges requires state-of-the-art techniques and technologies to ensure optimal performance.

Surface mount technology (SMT) assembly is a method where electronic components are mounted directly onto the surface of the PCB. This allows for a more compact and efficient design, which is essential for high-frequency applications.

High mix manufacturing refers to the ability to produce a wide variety of products in small quantities. This is important in RF circuit card assembly, where different applications may require unique designs and components.

Quality control involves rigorous testing at various stages of the manufacturing process to identify and rectify any defects. This includes testing for electrical properties, signal integrity, and overall performance.

Emerging technologies such as 5G, the Internet of Things (IoT), and advanced medical devices will drive the demand for more sophisticated RF circuits. Staying at the forefront of these developments is key to delivering high-quality, high-performance RF circuits.

In conclusion, RF circuit card assembly is a complex and specialized field that requires a combination of expertise, precision, and cutting-edge technology. By focusing on key factors such as PCB design, component placement, and quality control, manufacturers can produce high-quality RF circuits that deliver optimal performance in high-frequency applications. As technology continues to advance, the field of RF circuit card assembly will continue to evolve, driving innovation and excellence in the electronics industry.