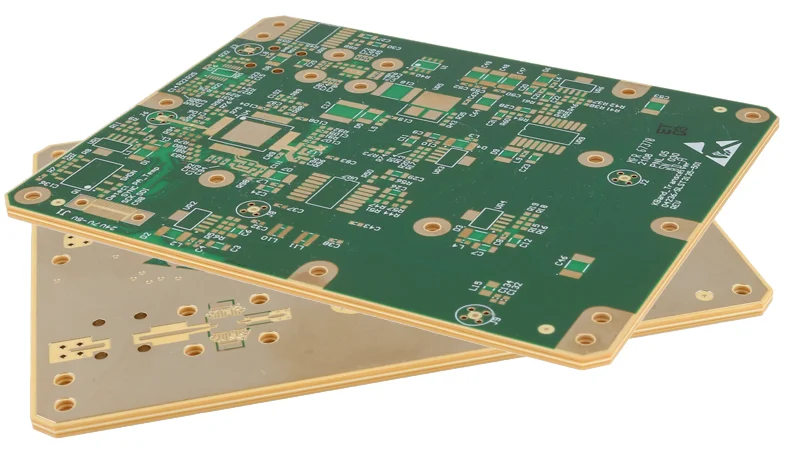

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing the physical platform for electrical connections and component support. Among the various types of PCBs, laminate PCB boards are particularly significant due to their versatility and essential role in high-performance applications. This article delves into the world of laminate PCB boards, exploring their composition, types, and applications, while shedding light on critical terms and concepts that define their performance.

A laminate PCB board is a type of PCB that uses layers of laminate materials to create a stable and reliable platform for electronic circuits. These laminates are composed of various materials, including glass fiber, epoxy resin, and copper foil, which are bonded together under high temperature and pressure. The resulting structure provides mechanical strength, electrical insulation, and thermal stability, making it suitable for a wide range of applications.

Glass fiber is a crucial component of laminate PCB boards. It provides the mechanical strength and rigidity necessary to support the PCB structure. Glass fiber is woven into a fabric and impregnated with resin to form the core of the laminate.

Epoxy resin is used to bond the glass fiber fabric and other materials together. It offers excellent adhesion, chemical resistance, and thermal stability. Epoxy resin is a key ingredient in various types of PCB laminates, including standard FR-4 laminate and high-performance FR-4.

Copper foil is laminated onto the surface of the board to create the conductive pathways for electrical signals. The thickness of the copper foil can vary depending on the application and design requirements.

Copper clad laminate (CCL) is the base material for most PCBs. It consists of a dielectric core material, such as glass fiber reinforced epoxy resin, covered with a layer of copper foil on one or both sides. CCL provides the foundation for the PCB manufacturing process.

There are several types of PCB laminates, each designed to meet specific performance requirements. Some of the most common types include:

FR-4 laminate is the most widely used PCB laminate material. It is made from glass fiber reinforced epoxy resin and offers a good balance of mechanical strength, electrical insulation, and thermal stability. FR-4 laminate is suitable for a wide range of applications, from consumer electronics to industrial equipment.

High performance FR-4 is a variant of standard FR-4 laminate with enhanced properties. It offers higher glass transition temperature (Tg), improved thermal stability, and better chemical resistance. High performance FR-4 is used in applications where higher temperatures and more demanding conditions are expected.

High Tg epoxy laminates are designed to withstand higher temperatures without degrading. They have a higher glass transition temperature (Tg) compared to standard epoxy laminates, making them suitable for high temperature and high frequency circuits.

Epoxy laminate is a general term for laminates made from epoxy resin. These laminates are known for their excellent adhesion, chemical resistance, and thermal stability. Epoxy laminates are used in a variety of PCB applications.

Multi layered PCBs consist of multiple layers of laminate materials stacked and bonded together. These boards allow for more complex circuit designs and higher component density. Multi layered PCBs are used in advanced electronic devices, such as smartphones and computer motherboards.

The dielectric constant of a laminate material affects the electrical performance of the PCB. It determines how well the material can store and transmit electrical energy. Materials with a low dielectric constant are preferred for high frequency circuits to minimize signal loss and interference.

The glass transition temperature (Tg) is the temperature at which the laminate material transitions from a rigid state to a more flexible state. A higher Tg indicates better thermal stability and resistance to deformation under high temperatures. High Tg epoxy laminates are used in applications where high temperature performance is critical.

The coefficient of thermal expansion (CTE) measures how much the laminate material expands and contracts with temperature changes. A lower CTE is desirable to minimize thermal stress and ensure the dimensional stability of the PCB.

Chemical resistance is an important property for laminates used in harsh environments. Epoxy resin and high performance FR-4 laminates offer good resistance to chemicals, ensuring the longevity and reliability of the PCB.

The process of manufacturing laminate PCB boards involves several steps, each critical to the quality and performance of the final product. Let's explore the key stages of the PCB manufacturing process.

The process begins with designing the PCB layout using specialized software. The design includes the placement of components, routing of electrical connections, and defining the layers of the board.

The selected laminate materials, such as FR-4 laminate or high Tg epoxy, are prepared for fabrication. This involves cutting the materials to the required size and cleaning them to remove any contaminants.

For multi layered PCBs, the individual layers of laminate materials are stacked and bonded together using heat and pressure. This creates a solid and stable structure that can support complex circuit designs.

Holes are drilled into the board to accommodate component leads and vias. Precision drilling equipment is used to ensure accurate hole placement and size.

The drilled holes are plated with copper to create electrical connections between the layers. The copper foil on the surface of the board is then etched to create the desired circuit pattern.

A solder mask is applied to the board to protect the copper traces and prevent solder bridges during component assembly. The silkscreen layer is added to provide labels and markings for components and test points.

The PCB undergoes final assembly, where components are mounted and soldered onto the board. The completed board is then tested to ensure it meets the required specifications and functions correctly.

Laminate PCB boards are used in a wide range of applications across various industries. Some common examples include:

Devices such as smartphones, tablets, and laptops rely on laminate PCB boards for their compact and high-performance designs.

Modern vehicles incorporate numerous electronic systems, from infotainment to advanced driver-assistance systems (ADAS). Laminate PCB boards are essential for developing and testing these systems.

Automation and control systems in industrial settings use laminate PCB boards for their durability and precision.

Medical devices, including diagnostic equipment and wearable health monitors, use laminate PCB boards for their reliability and performance.

A laminate PCB board is a type of PCB that uses layers of laminate materials, such as glass fiber, epoxy resin, and copper foil, to create a stable and reliable platform for electronic circuits.

Glass fiber provides the mechanical strength and rigidity necessary to support the PCB structure. It is woven into a fabric and impregnated with resin to form the core of the laminate.

The dielectric constant affects the electrical performance of the PCB. Materials with a low dielectric constant are preferred for high frequency circuits to minimize signal loss and interference.

The glass transition temperature (Tg) is the temperature at which the laminate material transitions from a rigid state to a more flexible state. A higher Tg indicates better thermal stability and resistance to deformation under high temperatures.

Multi layered PCBs consist of multiple layers of laminate materials stacked and bonded together. These boards allow for more complex circuit designs and higher component density.

High Tg epoxy laminates offer higher thermal stability and resistance to deformation under high temperatures, making them suitable for high temperature and high frequency applications.

Industries such as consumer electronics, automotive electronics, industrial automation, and medical devices use laminate PCB boards for various applications.

In conclusion, laminate PCB boards are a cornerstone of modern electronics, providing the foundation for reliable and high-performance circuit designs. By understanding the components, properties, and manufacturing process of laminate PCB boards, engineers and designers can continue to innovate and bring cutting-edge electronic devices to market.