Printed Circuit Boards (PCBs) are the backbone of modern electronics, connecting various components to create functional devices. Among the numerous elements that make up a PCB, the edge connector plays a crucial role in ensuring seamless connectivity and communication between different parts of an electronic system. In this comprehensive guide, we will delve into the world of PCB edge connectors, exploring their types, applications, and how they work, with a special focus on PCI Express and card edge connectors.

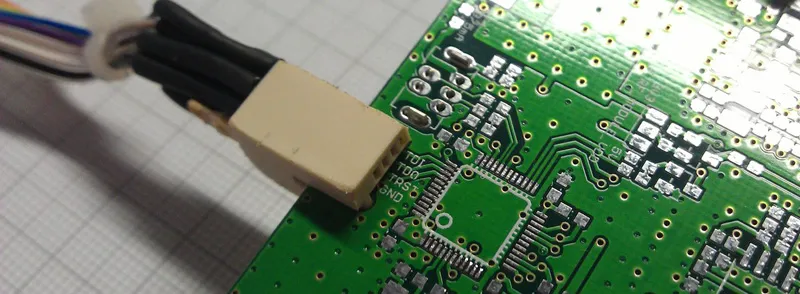

A PCB edge connector is a type of electrical connector that allows for the connection of a PCB to an external device or another PCB. These connectors are typically located on the edge of the PCB, hence the name, and they facilitate the transfer of power, signals, and data between different components or systems. The edge connector consists of a series of conductive pads or fingers that align with corresponding contacts in a mating connector, ensuring a secure and reliable connection.

There are several types of PCB edge connectors, each designed for specific applications and requirements. Some of the most common types include:

Card edge connectors are one of the most widely used types of PCB edge connectors. They feature a series of conductive pads along the edge of the PCB, which mate with corresponding contacts in a connector socket. Card edge connectors are commonly used in computer hardware, such as graphics cards, memory modules, and expansion cards.

PCI Express (Peripheral Component Interconnect Express) connectors are a specialized type of card edge connector used in high-speed data transfer applications. They are designed to provide high bandwidth and low latency connections, making them ideal for use in modern computer systems, including graphics cards, network cards, and storage devices.

Gold finger connectors are a type of card edge connector characterized by their gold-plated conductive pads. The gold plating provides excellent conductivity and resistance to corrosion, making these connectors suitable for high-reliability applications where signal integrity is critical.

Slot connectors are used to connect PCBs to a backplane or motherboard. They feature a series of conductive pads that mate with corresponding contacts in a slot on the backplane or motherboard, allowing for easy installation and removal of the PCB.

PCB edge connectors work by establishing an electrical connection between the conductive pads on the edge of the PCB and the contacts in a mating connector. When the PCB is inserted into the connector socket, the conductive pads align with the contacts, creating a secure and reliable connection. This allows for the transfer of power, signals, and data between the PCB and other components or systems.

The design and construction of PCB edge connectors are critical to ensuring a reliable connection. The conductive pads must be precisely aligned and spaced to match the contacts in the connector socket. Additionally, the materials used for the conductive pads and contacts must provide excellent conductivity and resistance to corrosion to ensure a long-lasting connection.

PCB edge connectors are used in a wide range of applications, from consumer electronics to industrial equipment. Some of the most common applications include:

PCB edge connectors are extensively used in computer hardware, including graphics cards, memory modules, and expansion cards. PCI Express connectors, in particular, are essential for high-speed data transfer between the motherboard and peripheral devices.

In telecommunications equipment, PCB edge connectors are used to connect various circuit boards and modules, ensuring reliable communication and data transfer.

Industrial automation systems rely on PCB edge connectors to connect various control and monitoring modules, enabling efficient and reliable operation of machinery and equipment.

From smartphones to gaming consoles, PCB edge connectors are used in a wide range of consumer electronics to connect various components and ensure seamless operation.

In automotive electronics, PCB edge connectors are used to connect various control modules and sensors, ensuring reliable operation of the vehicle's electronic systems.

PCB edge connectors offer several benefits, making them a popular choice for a wide range of applications. Some of the key benefits include:

PCB edge connectors provide a secure and reliable connection, ensuring consistent performance and reducing the risk of connection failures.

The design of PCB edge connectors allows for easy installation and removal of PCBs, making them ideal for applications where frequent maintenance or upgrades are required.

PCI Express connectors, in particular, offer high bandwidth and low latency connections, making them ideal for high-speed data transfer applications.

PCB edge connectors are compact and space-efficient, making them suitable for use in devices with limited space.

PCB edge connectors are available in a wide range of types and configurations, making them suitable for a variety of applications and requirements.

When selecting a PCB edge connector for your application, there are several factors to consider:

Consider the specific requirements of your application, including the type of signals or data being transferred, the required bandwidth, and the environmental conditions.

Choose the appropriate type of connector for your application, such as card edge connectors, PCI Express connectors, or gold finger connectors.

The material used for the contacts is critical to ensuring a reliable connection. Gold-plated contacts are often preferred for their excellent conductivity and resistance to corrosion.

Ensure that the conductive pads on the PCB are precisely aligned and spaced to match the contacts in the connector socket.

Consider the durability and longevity of the connector, especially if it will be subjected to frequent installation and removal.

A PCB edge connector is an electrical connector that allows for the connection of a PCB to an external device or another PCB. It consists of conductive pads on the edge of the PCB that mate with corresponding contacts in a connector socket.

Common types of PCB edge connectors include card edge connectors, PCI Express connectors, gold finger connectors, and slot connectors.

A PCI Express connector is a specialized type of card edge connector used for high-speed data transfer applications. It provides high bandwidth and low latency connections, making it ideal for use in modern computer systems.

Benefits of using PCB edge connectors include high reliability, easy installation and removal, high bandwidth, compact design, and versatility.

When choosing a PCB edge connector, consider factors such as application requirements, connector type, contact material, alignment and spacing, and durability.

In conclusion, PCB edge connectors are essential components in modern electronics, providing reliable and efficient connections between PCBs and other devices. By understanding the different types of connectors, their applications, and how they work, you can make informed decisions when selecting the right connector for your needs. Whether you're working with computer hardware, telecommunications equipment, or industrial automation systems, PCB edge connectors are critical to ensuring seamless connectivity and optimal performance.