In the world of electronics, power supplies are the unsung heroes that ensure our devices function smoothly. Among the various types of power supplies, the 5V power supply is one of the most commonly used, especially in small electronic projects and gadgets. This article delves deep into the intricacies of designing a 5V power supply PCB (Printed Circuit Board), exploring everything from the basics of DC power supplies to practical design tips. Whether you're a hobbyist or an engineer, this guide will equip you with the knowledge to create a reliable 5V power supply PCB.

Before diving into the specifics of a 5V power supply PCB, it's essential to understand the fundamentals of DC power supplies. DC (Direct Current) power supplies convert AC (Alternating Current) from the mains into a stable DC voltage. This stable voltage is crucial for powering electronic circuits and devices.

1. Linear Power Supplies: These are simple and provide a very stable output. However, they are not very efficient and can generate a lot of heat.

2. Switching Power Supplies: More efficient than linear power supplies, these use a high-frequency switching regulator to convert AC to DC. They are more complex but are preferred for their efficiency and compact size.

The 5V power supply is ubiquitous in electronics for several reasons:

Compatibility: Many microcontrollers, sensors, and other electronic components operate at 5V.

Availability: 5V regulators and components are readily available and cost-effective.

Versatility: A 5V power supply can be used in a wide range of applications, from simple LED circuits to complex microcontroller-based systems.

Designing a 5V power supply PCB involves several critical steps, from selecting components to laying out the PCB. Let's explore each step in detail.

The first step in designing a 5V power supply PCB is to define the requirements. Consider the following questions:

What is the input voltage range? This could be a standard AC mains voltage or a different DC voltage.

What is the maximum current requirement? Determine the maximum current your circuit will draw.

Are there any specific size constraints? This is particularly important for compact or portable devices.

What is the acceptable level of ripple and noise?This is crucial for sensitive electronic circuits.

Choosing the right components is vital for a reliable 5V power supply PCB. Here are the key components you'll need:

1. Transformer (if using AC input): Steps down the AC voltage to a lower AC voltage.

2. Rectifier: Converts AC to DC. A bridge rectifier is commonly used.

3. Filter Capacitors: Smooth out the rectified DC voltage.

4. Voltage Regulator: Maintains a stable 5V output. Popular options include the 7805 linear regulator or a switching regulator like the LM2596.

5. Inductors and Capacitors (for switching regulators): Used for filtering and stabilizing the output.

6. Protection Components: Such as fuses, diodes, and TVS (Transient Voltage Suppression) diodes to protect against surges and overcurrent.

Once you've selected the components, the next step is to create the schematic diagram. This diagram shows how each component is connected. Here are some tips for designing a clear and effective schematic:

Label all components clearly: Use descriptive names and values.

Group related components: For example, place all filtering capacitors near the rectifier.

Follow standard conventions: Use standard symbols and notation for components.

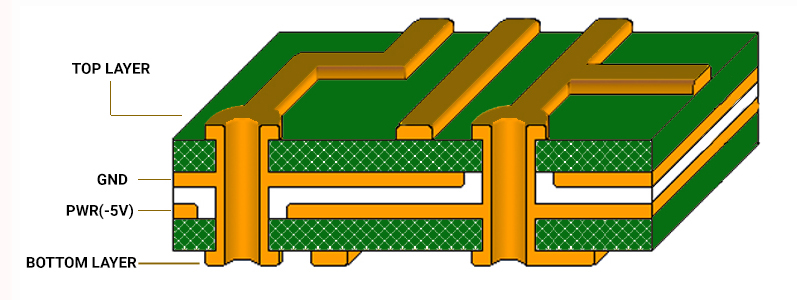

The PCB layout is where your design comes to life. A well-designed PCB layout ensures reliable operation and minimizes issues like noise and interference. Here are some best practices for laying out a 5V power supply PCB:

1. Component Placement: Place the voltage regulator and critical components in the center of the PCB to minimize trace lengths.

2. Ground Plane: Use a solid ground plane to reduce noise and provide a stable reference.

3. Trace Width: Ensure traces carrying high current are wide enough to handle the current without excessive heating.

4. Thermal Management: Provide adequate heat sinking for components that generate heat, such as the voltage regulator.

5. Decoupling Capacitors: Place decoupling capacitors close to the power pins of ICs to filter out noise.

6. Routing: Keep power and ground traces short and wide. Avoid running sensitive signal traces near high-current traces.

After designing the PCB, the next step is to create a prototype and test it. Here are some tips for effective prototyping and testing:

Visual Inspection: Check for any obvious errors or shorts on the PCB.

Continuity Testing: Use a multimeter to check for continuity in the traces.

Power-Up Testing: Gradually apply power and monitor the output voltage and current.

Load Testing: Test the power supply under different load conditions to ensure it can handle the maximum current.

If you encounter issues during testing, here are some common problems and their solutions:

No Output Voltage: Check for shorts, open connections, and component orientation.

Excessive Heat: Ensure components are properly rated for the current and have adequate heat sinking.

Ripple and Noise: Add additional filtering capacitors and ensure proper grounding.

A 5V power supply PCB can be used in a wide range of applications. Here are a few examples:

1. Microcontroller Projects: Many microcontrollers, such as the Arduino and Raspberry Pi, operate at 5V.

2. Sensor Modules: Many sensors and modules, such as temperature sensors and GPS modules, require a stable 5V supply.

3. Portable Devices: A compact 5V power supply PCB can be used in portable devices like battery chargers and handheld gadgets.

4. DIY Electronics: Hobbyists and makers often use 5V power supplies in their DIY projects.

Designing a 5V power supply PCB is a rewarding and essential skill for anyone involved in electronics. By understanding the basics of DC power supplies and following best practices in component selection, schematic design, PCB layout, and testing, you can create a reliable and efficient 5V power supply for your projects. Whether you're powering a simple LED circuit or a complex microcontroller system, a well-designed 5V power supply PCB will ensure your devices run smoothly and efficiently.

Remember, the key to a successful design is careful planning, attention to detail, and thorough testing. With these principles in mind, you'll be well on your way to mastering the art of 5V power supply PCB design. Happy designing!