In the world of mechanical keyboards, enthusiasts are always looking for ways to create the perfect typing experience. While keycaps and switches often steal the spotlight, there's an unsung hero at the core of every great custom keyboard: the PCB. The Printed Circuit Board (PCB) is the foundation upon which your dream keyboard is built, and customizing it can take your typing experience to a whole new level.

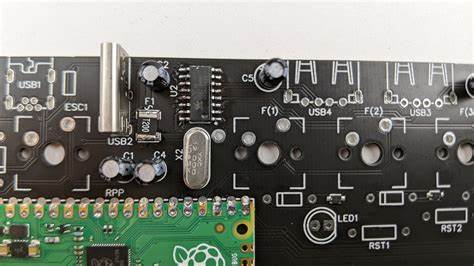

A custom mechanical keyboard PCB is the circuit board that connects all the electrical components of your keyboard. It's where the switches are mounted and where the magic happens to translate your keystrokes into signals your computer can understand. Unlike mass-produced PCBs found in off-the-shelf keyboards, custom PCBs offer a range of features and options that cater to the specific needs and preferences of keyboard enthusiasts.

1. Personalization: Custom PCBs allow you to choose the exact layout, size, and features you want in your keyboard.

2. Quality: Many custom PCBs are made with higher-quality materials and more precise manufacturing processes than mass-produced boards.

3. Programmability: Most custom PCBs support advanced firmware like QMK or VIA, giving you unprecedented control over your keyboard's functionality.

4. Unique Features: Want RGB underglow? Hot-swap sockets? A rotary encoder? Custom PCBs can accommodate these and more.

1. Microcontroller: The brain of the PCB, typically an ATmega32U4 or similar chip.

2. Switch Mounting Points: These determine the layout and size of your keyboard.

3. Diodes: These prevent "ghosting" when multiple keys are pressed simultaneously.

4. USB Port: For connecting your keyboard to your computer.

5. RGB LEDs: For backlighting or underglow effects (optional).

6. Hot-swap Sockets: Allow for easy switch swapping without soldering (optional).

7. Additional Features: Things like rotary encoders, OLED screens, or wireless modules can be added to some custom PCBs.

If you're tech-savvy and up for a challenge, you can design your own PCB from scratch. This process involves:

1. Choosing Your Layout: Decide on the size and arrangement of keys you want.

2. Selecting Components: Choose your microcontroller, diodes, and any additional features.

3. Creating the Schematic: Design the electrical connections between components.

4. Laying Out the PCB: Arrange the components and traces on the board.

5. Generating Production Files: Create the files needed for manufacturing.

For those who aren't ready to dive into PCB design, there are many open-source designs available that you can modify to suit your needs.

1. Hot-swap Sockets: These allow you to change switches without soldering, perfect for trying out different switch types.

2. RGB Lighting: Whether it's per-key backlighting or underglow effects, RGB adds a visual flair to your keyboard.

3. Split Designs: For ergonomic keyboards that can be separated into two halves.

4. Wireless Connectivity: Some custom PCBs support Bluetooth or other wireless protocols.

5. OLED Displays: Small screens that can show keyboard information or custom graphics.

6. Rotary Encoders: Knobs that can be programmed for volume control, scrolling, or other functions.

The firmware is the software that runs on your PCB's microcontroller. Most custom PCBs use open-source firmware like QMK (Quantum Mechanical Keyboard) or VIA. These allow for extensive customization of your keyboard's functionality, including:

1. Key Remapping: Change what each key does, create layers for different functions.

2. Macros: Program complex sequences of keystrokes to a single button.

3. Lighting Control: Customize RGB effects and animations.

4. Advanced Features: Implement things like tap dance (different actions for tapping vs holding a key) or leader keys.

Once you have your design ready, it's time to get it made. There are several PCB manufacturing services available online that cater to small-batch production. Some popular options include:

1. JLCPCB

2. RigaoElectronic

3. PCBWay

These services allow you to upload your design files and choose options like PCB color, thickness, and surface finish. They'll then manufacture and ship your custom PCBs to you.

With your custom PCB in hand, it's time to bring your keyboard to life. This typically involves:

1. Soldering switches (or installing them in hot-swap sockets)

2. Adding stabilizers for larger keys

3. Programming the firmware

4. Installing the PCB in a case

5. Adding keycaps

The result is a truly unique keyboard that's tailored to your exact specifications.

As the mechanical keyboard hobby continues to grow, we're seeing constant innovation in the world of custom PCBs. Some exciting trends include:

1. More Powerful Microcontrollers: Allowing for even more advanced features and customization.

2. Improved Wireless Technology: Better battery life and connectivity for wireless keyboards.

3. Integration with Other Devices: Custom PCBs that can interact with your computer or smartphone in new ways.

4. Sustainability: PCBs made with more environmentally friendly materials and manufacturing processes.

Custom mechanical keyboard PCBs are the unsung heroes of the keyboard world. They provide the foundation for creating truly unique and personalized typing experiences. Whether you're designing your own PCB from scratch or modifying an existing design, the world of custom PCBs offers endless possibilities for keyboard enthusiasts. So the next time you're planning your dream keyboard build, remember to give some serious thought to the PCB – it might just be the key to creating your perfect keyboard.

A: While some programming knowledge can be helpful, many custom PCBs come with user-friendly configurators that allow you to customize your keyboard without coding. However, if you want to dive deep into advanced features, learning a bit about programming can be beneficial.

Q2: Are custom PCBs more expensive than standard ones?

A: Custom PCBs can be more expensive due to their specialized features and smaller production runs. However, the cost can vary widely depending on the complexity of the design and the manufacturing process. Some basic custom PCBs can be quite affordable.

A: It depends on the PCB design. Some PCBs are designed for specific switch types (like Cherry MX-style or Alps), while others, especially those with hot-swap sockets, can accommodate a variety of switch types. Always check the PCB specifications before purchasing switches.

A: Designing a PCB from scratch requires a good understanding of electronics and PCB design software. It can be challenging for beginners but is certainly achievable with dedication and learning. Many keyboard enthusiasts start by modifying existing open-source designs before creating their own.

A: Not necessarily. Custom PCBs are often designed to fit specific case sizes and mounting styles. It's important to ensure that your PCB is compatible with your chosen case, or design your case around your PCB if you're going fully custom.