In today's fast-paced world, electric massagers have become an essential tool for relaxation and therapy. These devices are no longer just a luxury but a necessity for many, especially those dealing with chronic pain or stress. The backbone of these advanced electronic devices is the High Density Interconnect (HDI PCB) Printed Circuit Board assembly. This article delves into the intricacies of HDI PCB assembly and its significance in the realm of consumer electronics and medical devices.

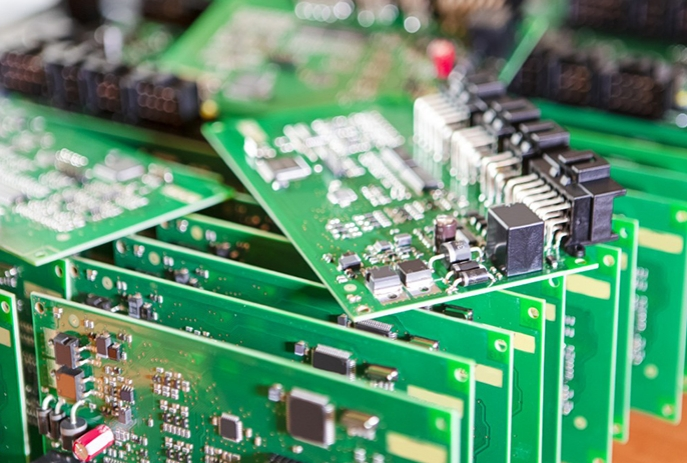

High Density Interconnect (HDI) technology refers to a type of PCB that has a higher wiring density per unit area compared to traditional PCBs. This is achieved through the use of finer lines and spaces, smaller vias, and capture pads, and higher connection pad density. HDI boards are characterized by multiple layers, which allow for more complex and compact designs.

HDI PCBs are pivotal in the development of modern electronic devices. They enable the creation of smaller, lighter, and more efficient gadgets. This is particularly important in consumer electronics, where there is a constant demand for compact and portable devices. The use of HDI technology allows manufacturers to pack more functionality into a smaller space, enhancing the performance and capabilities of the device.

Electric massagers rely heavily on HDI PCB assembly to ensure high performance and reliability. The multiple layers in HDI boards allow for better signal routing and reduced signal loss, which is crucial for the precise operation of these devices. The advanced HDI technology ensures that the massagers can deliver consistent and effective performance, whether they are used for relaxation or therapeutic purposes.

One of the significant advantages of HDI PCBs is their ability to support miniaturization. Electric massagers need to be compact and lightweight for ease of use and portability. HDI PCB assembly makes this possible by allowing more components to be integrated into a smaller area without compromising on functionality or performance.

Medical devices, including electric massagers, require a high level of durability and longevity. HDI PCBs are known for their robustness and ability to withstand harsh conditions. This makes them ideal for use in medical devices, where reliability and durability are paramount. The advanced HDI technology ensures that the electric massagers can endure prolonged use without any degradation in performance.

In the realm of consumer electronics, HDI PCBs are used in a wide range of devices, including smartphones, tablets, and wearables. The high density interconnect technology allows these gadgets to be more powerful and feature-rich while maintaining a sleek and compact design. Electric massagers, as part of this category, benefit immensely from HDI PCB assembly, enabling them to offer advanced features and superior performance.

HDI PCBs play a crucial role in the development of medical devices. These devices often require precise and reliable operation, which can be achieved through the use of HDI technology. Electric massagers used for therapeutic purposes must deliver consistent performance and withstand rigorous use. HDI PCB assembly ensures that these devices meet the stringent requirements of the medical industry.

One of the key benefits of HDI PCB assembly is improved signal integrity. The multiple layers and advanced design techniques reduce signal loss, ensuring that the electronic devices operate efficiently and accurately. This is particularly important in electric massagers, where precise control and operation are essential for effective therapy.

HDI PCBs are designed to manage heat more effectively than traditional PCBs. This is crucial for electronic devices that generate significant amounts of heat during operation. The improved thermal management ensures that the devices remain cool and function optimally, enhancing their lifespan and reliability.

The use of HDI technology provides greater design flexibility, allowing manufacturers to create innovative and complex designs. This flexibility is essential for developing cutting-edge consumer electronics and medical devices that meet the evolving needs of users.

HDI PCB assembly refers to the process of creating printed circuit boards with high wiring density per unit area. This involves the use of finer lines and spaces, smaller vias, and multiple layers to achieve a compact and efficient design.

HDI technology is crucial in electric massagers because it allows for the integration of more components into a smaller space, enhancing the device's performance and reliability. It also ensures better signal integrity and thermal management, which are essential for the precise operation of these devices.

HDI PCB assembly benefits consumer electronics by enabling the creation of smaller, lighter, and more powerful devices. The high density interconnect technology allows for more functionality to be packed into a compact design, enhancing the overall performance and capabilities of the gadgets.

Yes, HDI PCBs are known for their durability and ability to withstand harsh conditions. This makes them ideal for use in both consumer electronics and medical devices, where reliability and longevity are crucial.

HDI PCBs are used in a wide range of medical devices, including electric massagers, diagnostic equipment, and monitoring devices. The high density interconnect technology ensures that these devices operate reliably and accurately, meeting the stringent requirements of the medical industry.

HDI PCB assembly is a game-changer in the world of consumer electronics and medical devices. The advanced HDI technology enables the creation of compact, efficient, and reliable devices, including electric massagers. By reducing signal loss, improving thermal management, and offering greater design flexibility, HDI PCBs ensure that these devices deliver superior performance and durability. As technology continues to evolve, the role of HDI PCB assembly in developing innovative electronic devices will only become more significant.